Flat plate type membrane module integrated with feed liquid heating function and application thereof in membrane distillation

A flat-plate membrane and integrated material technology, applied in the field of membrane separation, can solve the problems of reducing MD separation efficiency, transmission power loss, etc., and achieve the effects of reducing the impact of the boundary layer, improving energy efficiency, and enhancing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

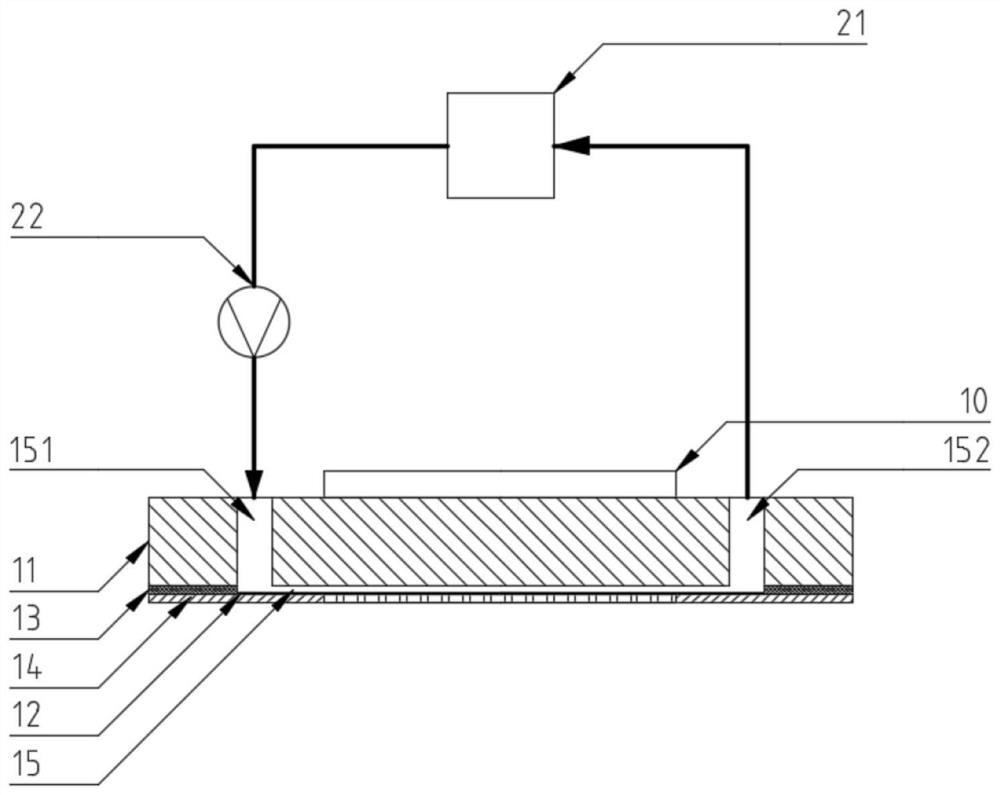

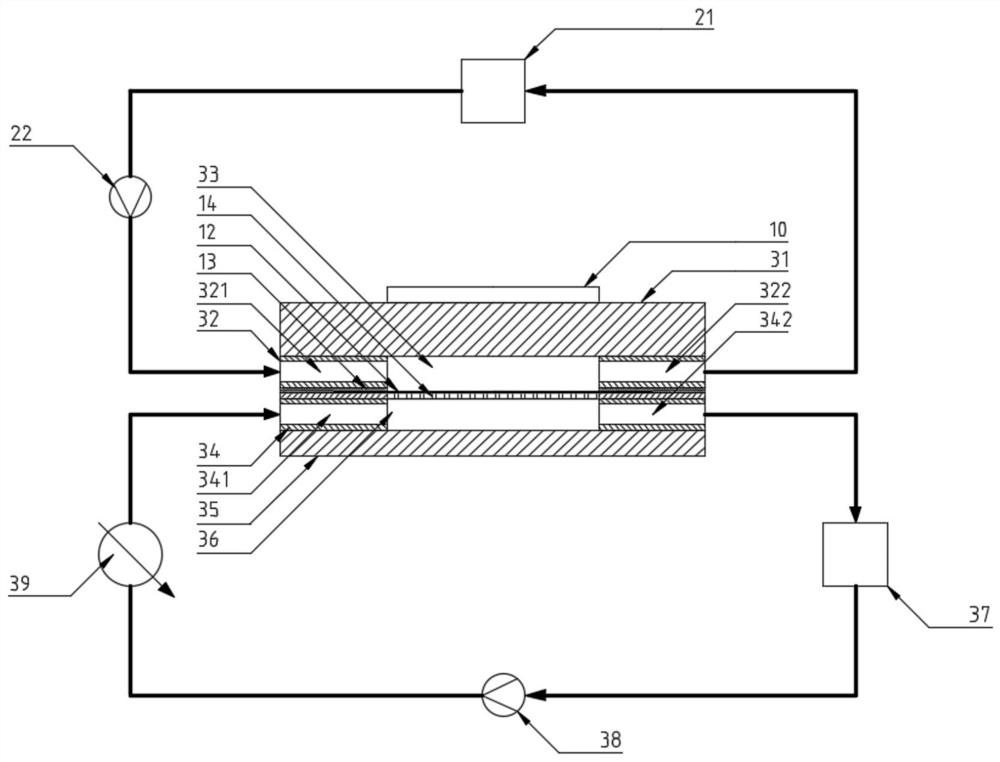

[0049] A DCMD system for concentration and desalination of brine is constructed by using the membrane module of this embodiment. Such as Figure 4 As shown, the membrane assembly including the integrated heating component adopting the U-shaped flow channel design scheme of the present invention, and as figure 2 The process of the feed liquid side and the process of the permeate side are the same as those of the comparative example.

[0050] The membrane module with integrated heating components adopts U-shaped flow channel design, and through the inlet and outlet channels set perpendicular to the membrane surface, a sufficiently small distance between the heating plate and the membrane surface can be obtained, so that the liquid on the surface of the microporous hydrophobic membrane 12 can be heated The plates 11 are heated efficiently, thereby significantly increasing the separation performance. An automatic control electric heating element 10 with a rated power of 120W is...

Embodiment 2

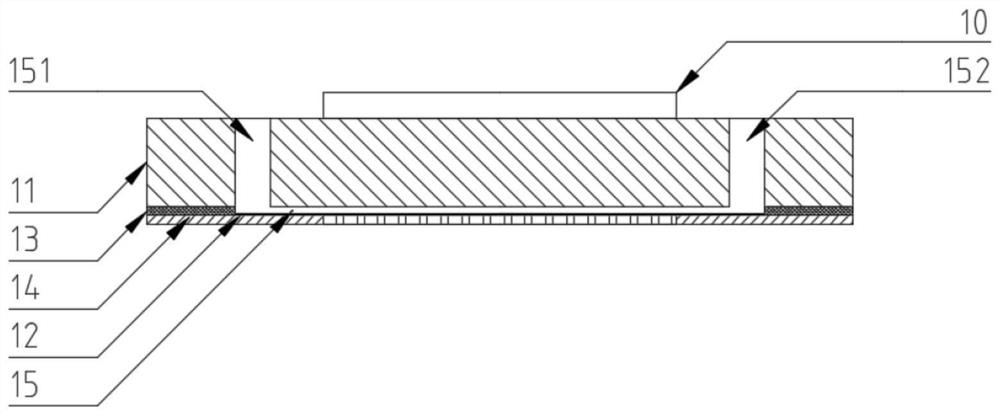

[0057] The same DCMD system as in Example 1 was used for concentration and desalination of brine, wherein the sealing gasket 13 was a 1.5 mm thick PTFE gasket, and other equipment, processes and operating parameters were the same as in Example 1. The material-liquid side channel 15 enclosed by the heating plate 11, the hydrophobic membrane 12 and the gasket 13 has a cross section as figure 1 In the U-shape shown, the actual distance between the heating plate 11 and the membrane surface 12 should be smaller than the thickness of the gasket 13 due to the deformation of the gasket under the clamping of the fastening bolts of the membrane module. The measured result is 1.02mm. After testing, the membrane flux of this embodiment 2 is 50.1kg / m 2 -h.

Embodiment 3

[0059] The same DCMD system as in Example 1 was used to carry out concentration and desalination of brine. Wherein the sealing gasket 13 adopts 2.0mm thick PTFE gasket, and other equipment, process and operating parameters are all the same as in embodiment 1. The material-liquid side channel 15 enclosed by the heating plate 11, the microporous hydrophobic membrane 12 and the sealing gasket 13 has a cross section as figure 1 In the U-shape shown, the actual distance between the heating plate 11 and the microporous hydrophobic membrane 12 should be smaller than the thickness of the gasket 13 due to the deformation of the gasket under the clamping of the fastening bolts of the membrane module. The measured result is 1.80mm. After testing, the membrane flux of this embodiment 3 is 43kg / m 2 -h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com