Intermediate material particle step-by-step screening device for rumen bypass product processing

A screening device and rumen-passing technology, which is applied in the field of step-by-step screening devices for intermediate material particles in the processing of rumen-passed products, can solve the problems of reducing screening efficiency and easy blockage of screen holes, so as to improve the degree of refinement and meet the requirements of processing. , to solve the effect of blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

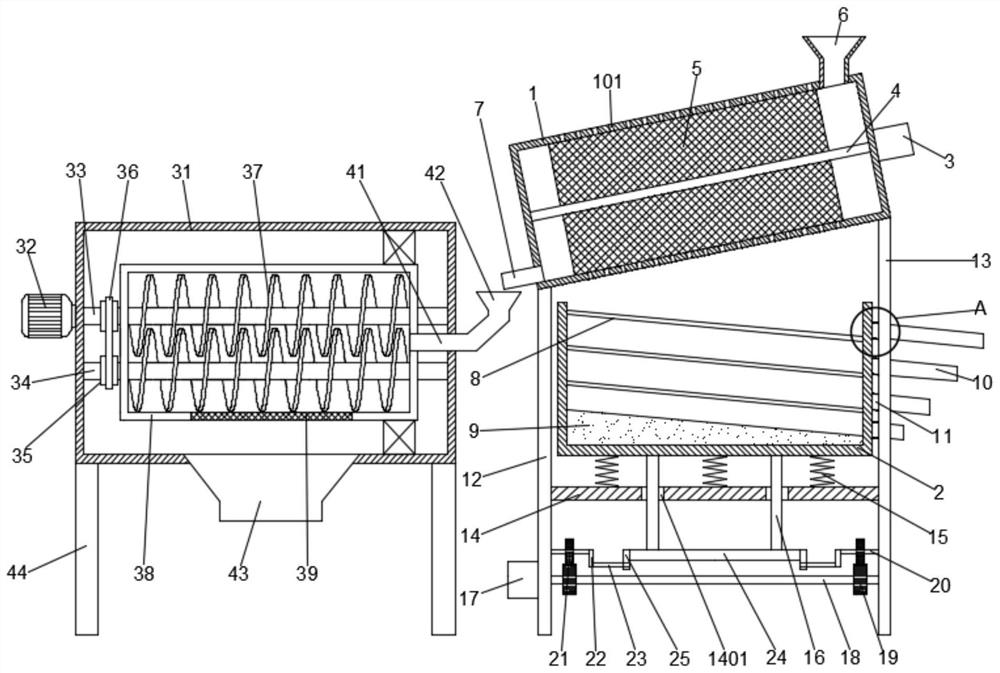

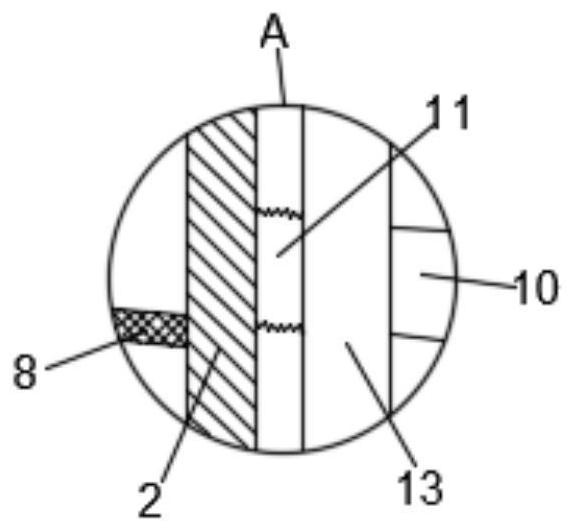

[0036] Such as Figure 1-7 As shown, a step-by-step screening device for processing intermediate material particles of rumen products, including a trommel 1, a sieve box 2 and a transmission box 31;

[0037]The middle part of the trommel 1 is provided with a sieve hole 101, and the trommel 1 is arranged obliquely. The upper side of the higher end of the trommel 1 is provided with a feed hopper 6 communicating with the interior thereof. The bottom of the lower end of the trommel 1 is There is a discharge pipe 7 communicating with the inside, and the right end of the transfer box 31 is provided with a connecting pipe 41 communicating with the inside, and the connecting pipe 41 is located below the discharge pipe 7; qualified particles fall through the sieve hole 101 into the Refined screening is carried out in the sieve box 2, and the larger lump particles enter the transfer box 31 through the discharge pipe 7 and the connecting pipe 41 for processing.

[0038] The bottom of th...

Embodiment 2

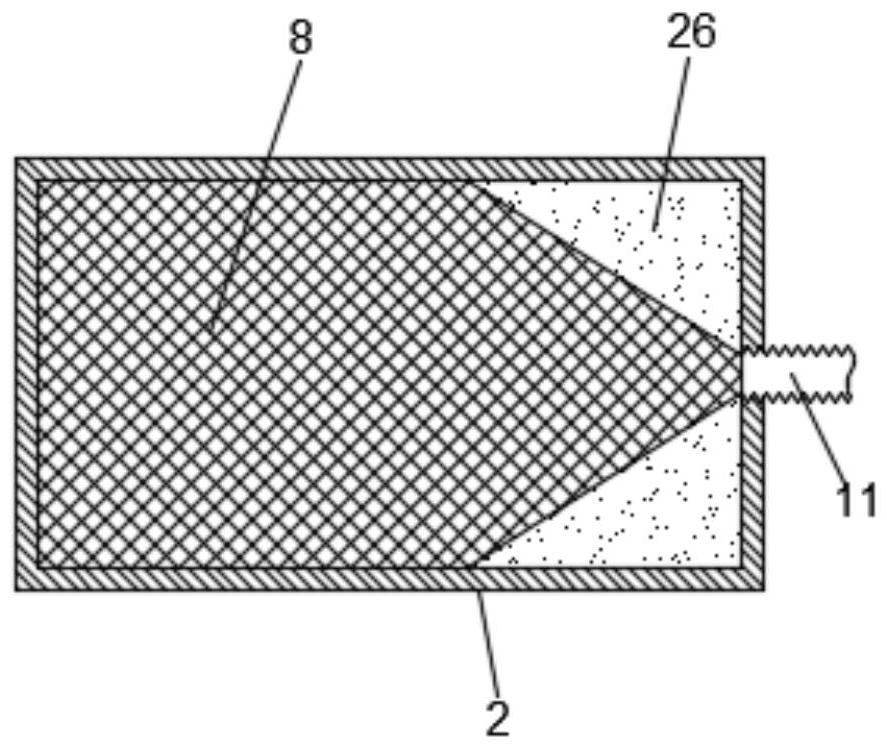

[0045] On the basis of Example 1, such as Figure 6 and Figure 7 As shown; the side of the rotary filter screen 5 away from the transmission shaft 4 is fixedly equipped with a connecting plate 27, and the side of the connecting plate 27 away from the rotary filter screen 5 is clamped with a cleaning plate 28, and the cleaning plate 28 and the draw-in groove 2701 A compression spring 29 is fixedly installed between them, and a brush 30 is fixedly installed on the side of the cleaning plate 28 close to the drum screen 1 , and the brush 30 is in close contact with the inner wall of the drum screen 1 .

[0046] Under the extrusion effect of the side wall of the drum screen 1, the cleaning plate 28 is pressed tightly inside the clamping groove 2701, and the action of the connecting plate 27 drives the cleaning plate 28 to rotate synchronously with the rotating screen 5, and through the cleaning action of the brush 30, the The rumen-passed product particles stuck in the screen hol...

Embodiment 3

[0049] On the basis of Example 2, such as Figure 8-10 As shown; the bottom of the transmission box 31 is fixedly equipped with several groups of legs 44, the middle part of the transmission box 31 is installed with a crushing cylinder 38 through bearing rotation, and the end of the connecting pipe 41 away from the discharge pipe 7 is connected with the interior of the crushing cylinder 38. The left side wall of the transmission box 31 is fixedly installed with a third motor 32, the output shaft of the third motor 32 penetrates the side wall of the transmission box 31 and is fixedly installed with a first crushing shaft 33, and the lower side of the first crushing shaft 33 is provided with There is a second crushing shaft 34, and the first crushing shaft 33 and the second crushing shaft 34 are fixedly equipped with pulleys 35 near the end of the third motor 32, and the two sets of pulleys 35 are connected by connecting belts 36. The first crushing shaft 33 and the middle part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com