Shape-controllable silicon dioxide nano array and preparation method and application thereof

A silicon dioxide and nanoarray technology, applied in the field of nanomaterials, can solve the problems of complex processing process and difficult to control surface structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

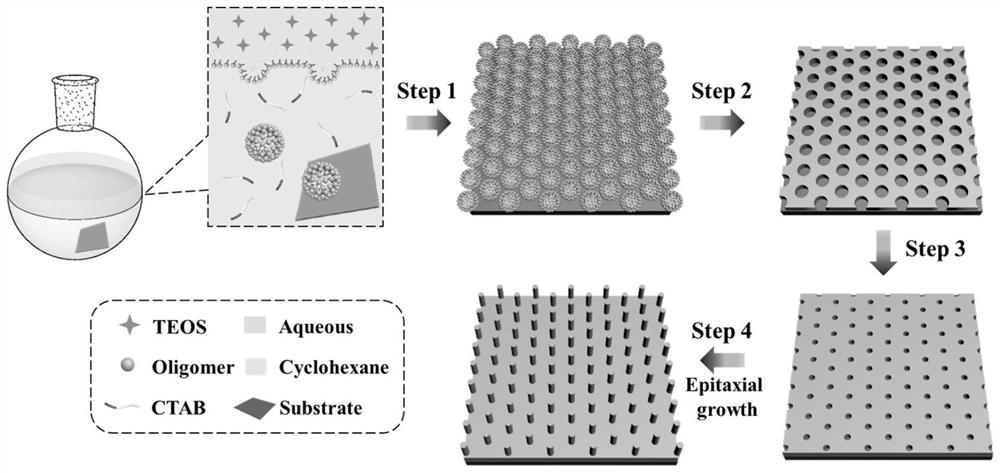

[0054] Growth of silica nanoarrays on silicon wafers:

[0055] (1) Dissolve 0.5 wt.% cetyltrimethylammonium bromide (CTAB) and 0.008 wt.% sodium hydroxide in water in turn to obtain a clear solution, and control the temperature at 60 °C;

[0056] (2) Add silicon wafers and continue to stir at 60 °C;

[0057] (3) Add a mixed solution of cyclohexane and tetraethylorthosilicate (TEOS), and control the volume ratio of cyclohexane, TEOS and water to 6: 1.5: 10;

[0058] (4) Control the temperature at 60 °C and react for 48 h;

[0059] (5) After the reaction is over, take out the silicon wafer and wash it.

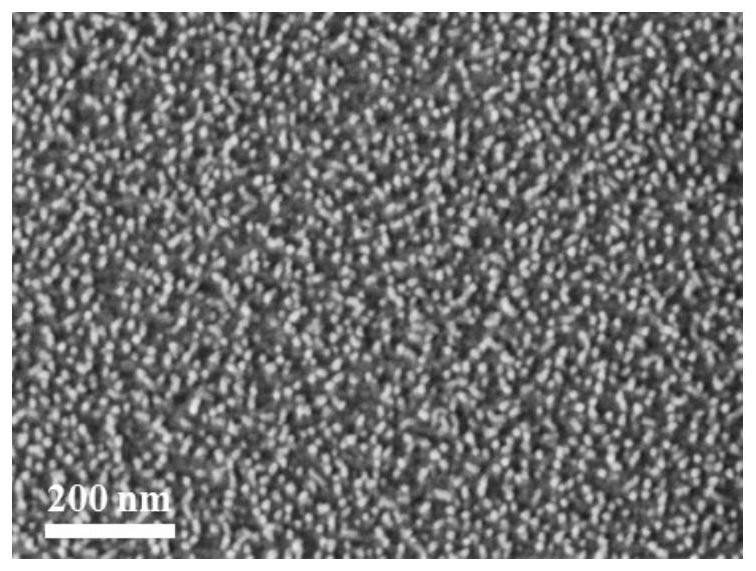

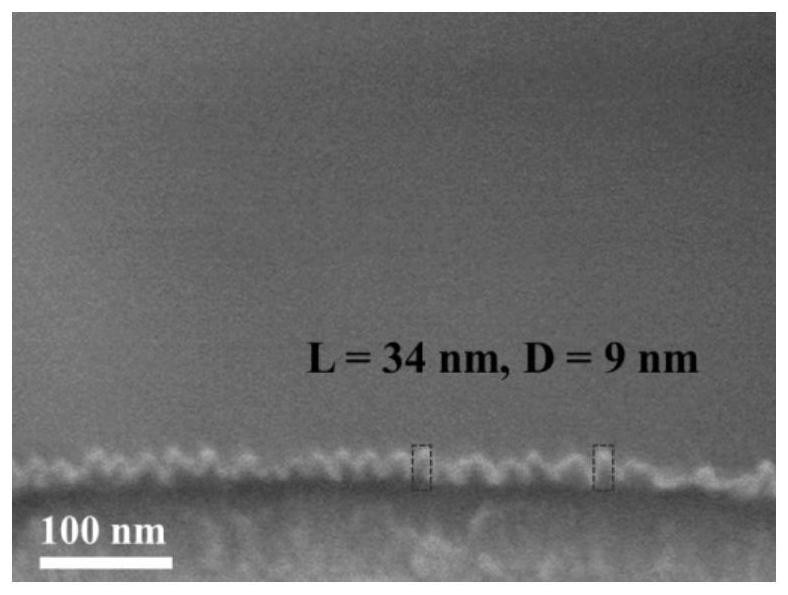

[0060] The silicon dioxide nanoarray layer grown on the silicon wafer was obtained, and the distribution density of the silicon dioxide nanoarray (spine) was 510 nanothorns / μm 2 , the average distance between adjacent silica nanopeaks is 46 nm. like Figure 4 , Figure 5 shown.

Embodiment 2

[0062] Growth of silica nanoarrays on glass rods:

[0063] (1) Dissolve 2 wt.% cetyltrimethylammonium bromide (CTAB) and 0.01 wt.% sodium hydroxide in water in turn to obtain a clear solution, and control the temperature at 60 °C;

[0064] (2) Add a glass rod and continue stirring at 60 °C;

[0065] (3) Add a mixed solution of cyclohexane and tetraethylorthosilicate (TEOS), and control the volume ratio of cyclohexane, TEOS and water to 6: 1.5: 10;

[0066] (4) Control the temperature at 60 °C and react for 48 h;

[0067] (5) After the reaction, the glass rod was taken out and washed to obtain a silicon dioxide nano-array layer grown on the glass rod. like Figure 6 , Figure 7 shown.

Embodiment 3

[0069] Growth of silica nanoarrays on glass tubes:

[0070] (1) Dissolve 2 wt.% cetyltrimethylammonium bromide (CTAB) and 0.01 wt.% sodium hydroxide in water in turn to obtain a clear solution, and control the temperature at 60 °C;

[0071] (2) Add the glass tube and continue stirring at 60 °C;

[0072] (3) Add a mixed solution of cyclohexane and tetraethylorthosilicate (TEOS), and control the volume ratio of cyclohexane, TEOS and water to 6: 1.5: 10;

[0073] (4) Control the temperature at 60 °C and react for 48 h;

[0074] (5) After the reaction, the glass tube was taken out and washed to obtain a silicon dioxide nano-array layer grown on the glass tube. like Figure 8 , Figure 9 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com