Method for preparing bio-organic fertilizer from kitchen garbage

A bio-organic fertilizer and kitchen waste technology is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, and organic fertilizers. Social effects, improved crop growth, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

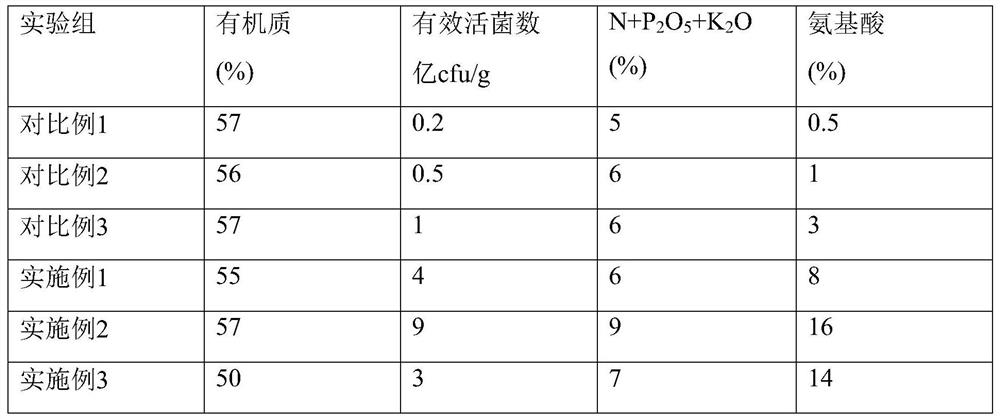

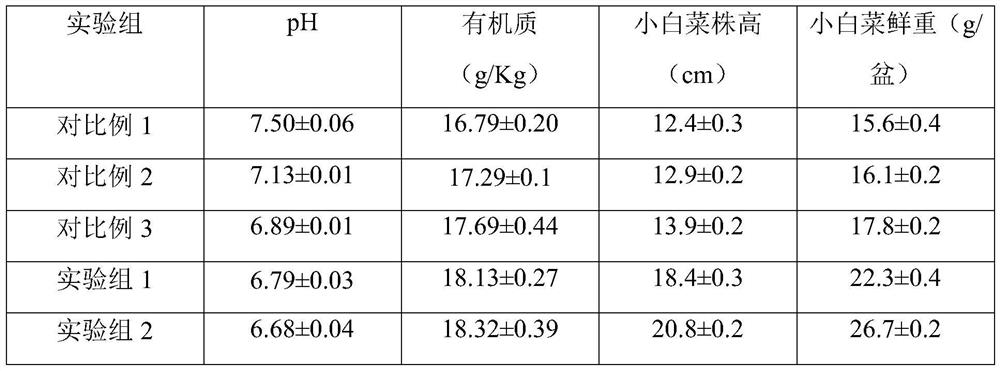

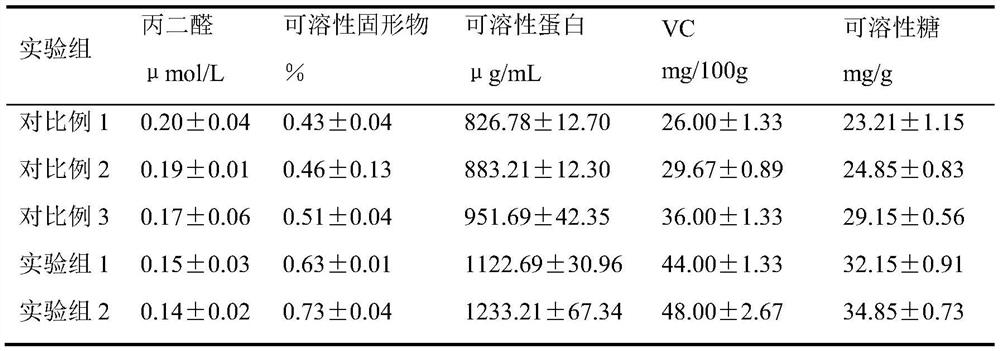

Examples

Embodiment 1

[0037] The method of the bio-organic fertilizer of the present embodiment may further comprise the steps:

[0038] (1) Collect the kitchen waste after garbage sorting, its moisture content is 80%, and use it after being crushed to 12-60mm;

[0039] (2) With straw as the substrate, the particle size after crushing is 0.5cm;

[0040] (3) Primary fermentation: Mix kitchen waste and straw at a mass ratio of 2:1, then add a total mass of 1‰ decomposed bacteria (Baiyibao EM bacteria), adjust the moisture content to 60%, and start fermentation for 7 days , turn the pile once a day, and keep the temperature above 50°C;

[0041] (4) Secondary fermentation: add duck feathers with a total mass of 10% to the fermented product after the first fermentation, and then add a total mass of 0.1% feather-degrading bacteria agent, and ferment again for 7 days to finally obtain bioorganic Fat.

Embodiment 2

[0043] The method of the bio-organic fertilizer of the present embodiment may further comprise the steps:

[0044] (1) Collect the kitchen waste after garbage sorting, its moisture content is 70%, and use it after crushing to 12-60mm;

[0045] (2) With straw as the substrate, the particle size after crushing is 1cm;

[0046] (3) Primary fermentation: Mix kitchen waste and straw at a mass ratio of 3:1, then add a decomposing bacterial agent with a total mass of 2‰, adjust the moisture content to 50%, start fermentation for 7 days, turn the pile once a day, and keep the temperature Above 50°C;

[0047] (4) Secondary fermentation: add chicken feathers with a total mass of 15% to the fermented product after the first fermentation, and then add a total mass of 0.5% feather-degrading bacteria agent, and ferment again for 10 days to finally obtain bio-organic fertilizer .

Embodiment 3

[0049] The method of the bio-organic fertilizer of the present embodiment may further comprise the steps:

[0050](1) Collect the kitchen waste after garbage sorting, its moisture content is 80%, and use it after being crushed to 12-60mm;

[0051] (2) With straw as the substrate, the particle size after crushing is 1cm;

[0052] (3) Primary fermentation: Mix kitchen waste and straw at a mass ratio of 5:1, then add a total mass of 2‰ of decomposing bacteria, adjust the moisture content to 40%, start fermentation for 9 days, turn the pile once a day, and keep the temperature Above 50°C;

[0053] (4) Secondary fermentation: Add chicken feathers with a total mass of 20% to the fermented product after the first fermentation, and then add a total mass of 1% feather-degrading bacteria agent, and ferment again for 7 days to finally obtain bio-organic fertilizer .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com