Acylhydrazone bond-based self-repairing polymer hydrogel and preparation method thereof

A polymer and self-healing technology, which is applied in the field of self-repairing polymer hydrogels based on acylhydrazone bonds and their preparation, can solve the problems of difficult grafting of reversible acylhydrazone bonds, cumbersome grafting steps, and low product yield, etc. Good biocompatibility, high self-healing efficiency, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

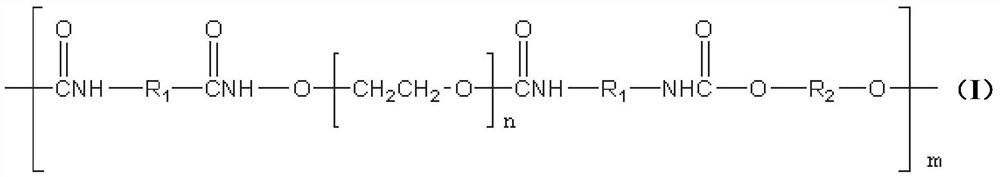

[0021] In one embodiment of the present invention, a kind of preparation method of self-healing polymer hydrogel based on acylhydrazone bond is provided, and the method steps are as follows:

[0022] Dissolving polyethylene glycol, aldehyde-containing double-terminal dihydroxy compound and catalyst in a solvent, stirring evenly, adding diisocyanate, and reacting to obtain a side chain aldehyde-containing polymer (BA-PU) solution;

[0023] After the BA-PU solution was cooled down, a DMF solution of triazine trihydrazide was added, stirred evenly, and left to stand at room temperature for reaction to obtain a self-healing polymer gel (AH-PU) based on an acylhydrazone bond; the prepared AH-PU Soak in deionized water and change the water regularly to obtain a self-healing polymer hydrogel (AH-WPU) based on acylhydrazone bonds;

[0024] Preferably, the BA-PU solution is cooled to 0-5°C;

[0025] Preferably, after stirring evenly, the step of degassing under reduced pressure is als...

Embodiment 1

[0055] Dissolve 50g of polyethylene glycol (10000g / mol), 0.45g of 2,3-dihydroxypropanal and 0.1g of stannous octoate in 30mL of DMF, stir well, add 2.22g of isophorone diisocyanate, and heat up under mechanical stirring React at 85° C. for 3 hours to obtain a branched chain aldehyde-based polymer (BA-PU) solution with a mass concentration of 65%.

[0056] Cool the BA-PU solution to 2°C, add 30mL of DMF solution in which 2.42g of triazine trihydrazide was dissolved, stir evenly, remove the gas under reduced pressure, then slowly pour it into the mold, and let it stand at room temperature for 4 h, Obtained self-healing polymer gel (AH-PU) based on acylhydrazone bonds. AH-PU was soaked in deionized water for 6 days, and the water was changed every 12 hours to obtain the self-healing polymer hydrogel AH-WPU-1 based on acylhydrazone bond.

Embodiment 2

[0058] Dissolve 80g polyethylene glycol (16000g / mol), 0.76g 2,4-dihydroxybenzaldehyde and 0.09g dibutyltin dilaurate in 30mL DMF, stir evenly, add 2.33g isophorone diisocyanate, mechanically stir , the temperature was raised to 85° C. for 3 h to obtain a polymer (BA-PU) solution with a mass concentration of 75% branched chain aldehyde group.

[0059] Cool the BA-PU solution to 3°C, add 30mL DMF solution in which 2.66g of triazine trihydrazide was dissolved, stir evenly, remove the gas under reduced pressure, then slowly pour it into the mold, and let it stand for 4 hours at room temperature. A self-healing polymer gel (AH-PU) based on acylhydrazone bonds was obtained. AH-PU was soaked in deionized water for 9 days, and the water was changed every 12 hours to obtain the self-healing polymer hydrogel AH-WPU-2 based on acylhydrazone bonds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com