Shell fruit and vegetable cleaning agent as well as preparation method and application thereof

A fruit and vegetable cleaning agent and shell technology, applied in the field of daily chemicals, can solve the problems of no antibacterial effect and high cost of raw materials, achieve good sterilization effect, improve adsorption efficiency, and improve the effect of solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

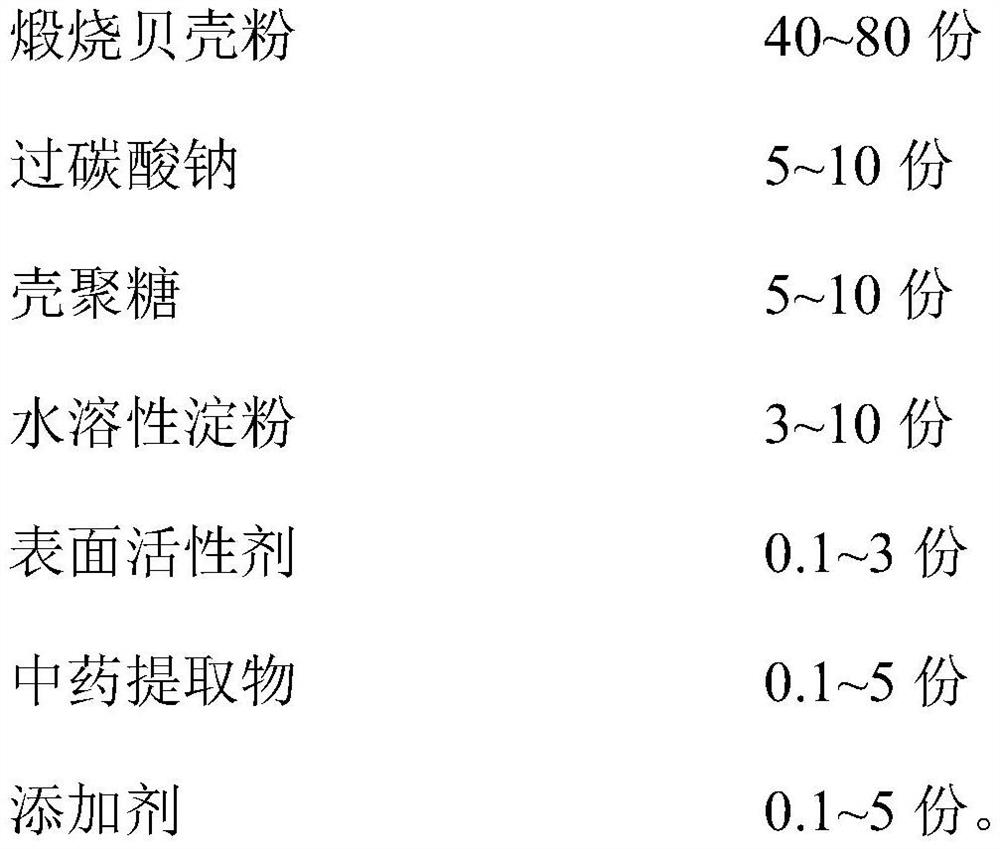

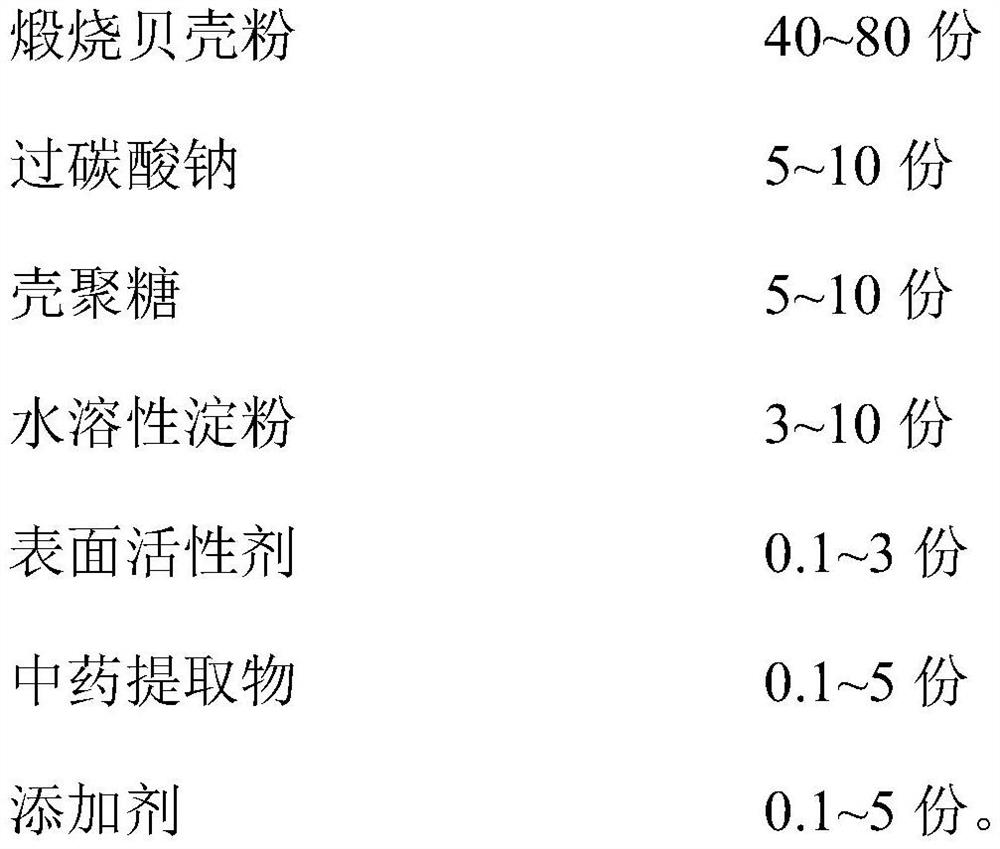

[0055] This embodiment provides a shell fruit and vegetable cleaning agent, which specifically includes the following components:

[0056]

[0057] The shell fruit and vegetable cleaning agent is prepared by the following method:

[0058] (1) Add the shells to a high-temperature calciner for gradient calcination, first calcining at 50°C for 10 minutes, then raising the temperature to 100°C for 30 minutes, then raising the temperature to 200°C for 10 minutes, then raising the temperature to 400°C for 60 minutes, and again Heat up to 800°C for 15 minutes, heat up to 1000°C for 60 minutes, then heat up to 1100°C for 30 minutes;

[0059] After the calcination is completed, the shells are naturally cooled in the muffle furnace (in order to accelerate the cooling process, nitrogen can also be blown to cool down);

[0060] (2) The cooled shells are taken out, powdered, digested, and sieved to prepare calcined shell powder, and the particle size range of the calcined shell powder ...

Embodiment 2

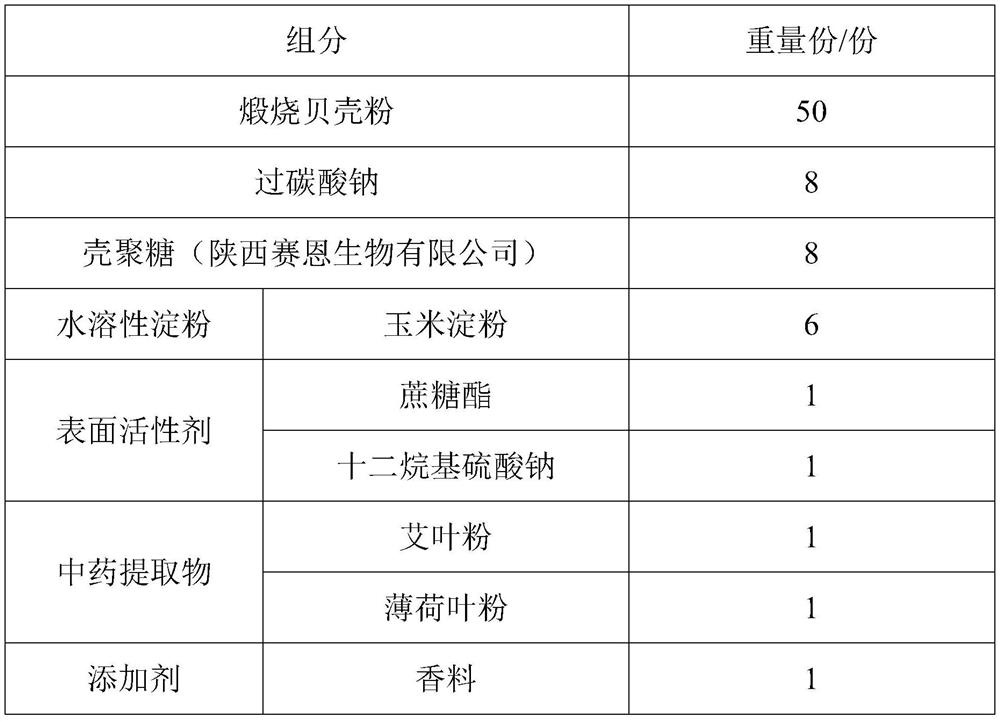

[0063] This embodiment provides a shell fruit and vegetable cleaning agent, which specifically includes the following components:

[0064]

[0065] The shell fruit and vegetable cleaning agent is prepared by the following method:

[0066] (1) Preparation of calcined shell powder: add the shells to a high-temperature calciner for gradient calcination, first calcining at 80°C for 10 minutes, then heating up to 120°C for 25 minutes, then raising the temperature to 300°C for 8 minutes, and then raising the temperature to 500°C Calcining for 40 minutes, then raising the temperature to 800°C for 10 minutes, raising the temperature to 1000°C for 40 minutes, then raising the temperature to 1100°C for 20 minutes, blowing nitrogen to cool the shell after the calcination;

[0067] (2) The cooled shells are taken out, powdered, digested, and sieved to prepare calcined shell powder, and the particle size range of the calcined shell powder is 100-200 mesh;

[0068] (3) Mix calcined shel...

Embodiment 3

[0070] This embodiment provides a shell fruit and vegetable cleaning agent, which specifically includes the following components:

[0071]

[0072] The shell fruit and vegetable cleaning agent is prepared by the following method:

[0073] (1) Preparation of calcined shell powder: add the shells to a high-temperature calciner for gradient calcination, first calcining at 40°C for 12 minutes, then heating up to 110°C for 35 minutes, then raising the temperature to 120°C for 12 minutes, and then raising the temperature to 300°C Calcining for 60 minutes, then raising the temperature to 500°C for 20 minutes, then raising the temperature to 800°C for 60 minutes, then raising the temperature to 1000°C for 40 minutes, blowing nitrogen to cool the shell after the calcination;

[0074] (2) The cooled shells are taken out, powdered, digested, and sieved to prepare calcined shell powder, and the particle size range of the calcined shell powder is 100-200 mesh;

[0075] (2) Mix calcined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com