High-strength corrosion-resistant cartridge case and preparation method thereof

A corrosion-resistant, high-strength technology, which is applied in the field of high-strength corrosion-resistant bullet casings and their preparation, can solve problems such as not being able to meet military applications, and achieve the effects of improving intergranular corrosion resistance, reducing weight, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

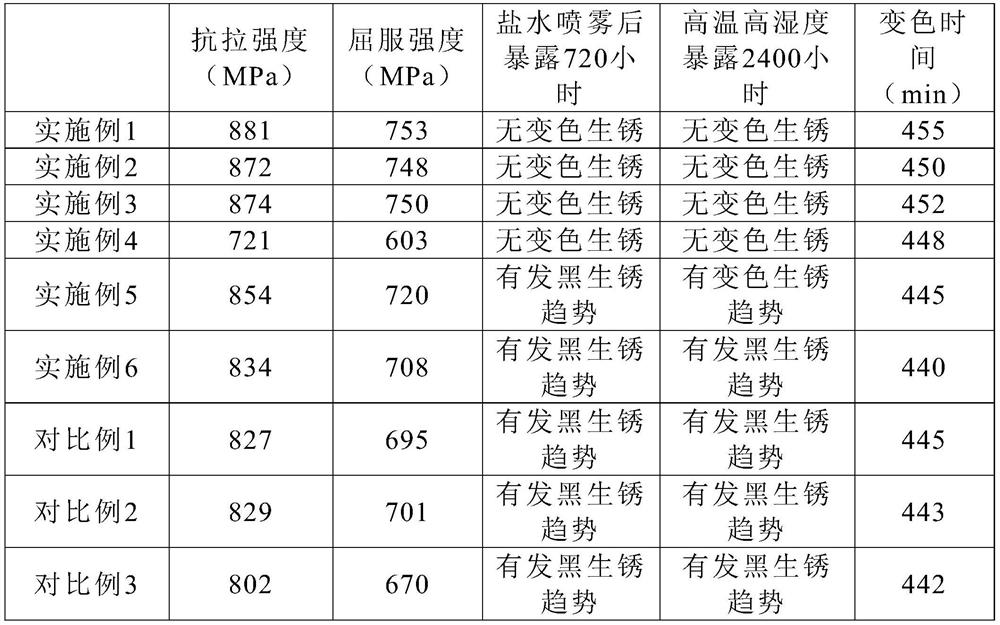

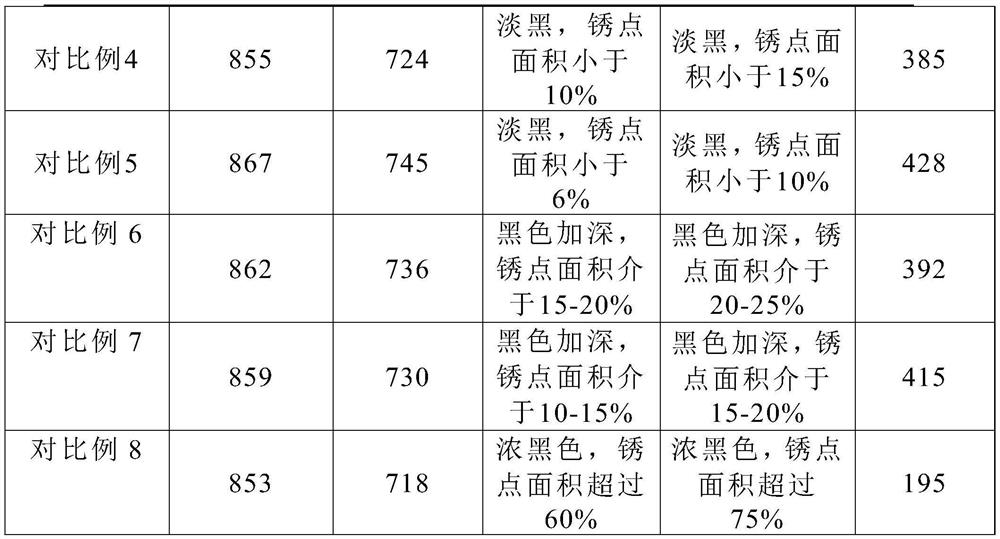

Examples

Embodiment 1

[0028] Weigh the following raw materials according to mass percentage: Zn: 7.5%, Mg: 2.5%, Cu: 8.0%, Li: 1.2%, Zr: 2.1%, Mn: 1.7%, Sm: 0.7%, and the balance is Al and unavoidable Impurities, and smelting, billet; Extrude the billet at a speed of 8mm / s at 450°C;

[0029] For heat treatment of molded parts, firstly perform primary solution treatment at 420-℃ for 3 hours, then perform secondary solution treatment at 470℃ for 2 hours; then perform primary aging treatment at 140℃ for 20 hours, and finally at 180℃ 24h secondary aging treatment;

[0030] Carry out surface cleaning on the cartridge case, firstly treat it with an aqueous solution composed of sodium hydroxide with a concentration of 7g / L and sodium bicarbonate with a concentration of 13g / L at 55°C for 6 minutes, then wash with water, and then wash it with water at 85°C with a concentration of 320ml / L of H 2 SO 4 (98%) and a concentration of 430ml / L of H 3 PO 4 (85%) mixed solution composed of processing 45s, washe...

Embodiment 2

[0034] Weigh the following raw materials Zn: 5.2%, Mg: 1.5%, Cu: 7.5%, Li: 0.8%, Zr: 1.2%, Mn: 1.5%, Sm: 0.6%, and the balance is Al and unavoidable Impurities, and smelting, billet; Extrude the billet at a speed of 6mm / s at 420°C;

[0035] Heat treatment of molded parts, firstly carry out primary solution treatment at 400°C for 3 hours, then carry out secondary solution treatment at 450°C for 2 hours; then carry out primary aging treatment at 130°C for 24 hours, finally at 170°C Carry out 28h secondary aging treatment;

[0036] Carry out surface cleaning on the cartridge casing, firstly treat it with an aqueous solution composed of sodium hydroxide with a concentration of 6g / L and sodium bicarbonate with a concentration of 12g / L at 50°C for 8 minutes, then wash with water, and then wash it with water at a concentration of 300ml / L at 80°C. L of H 2 SO 4 (98%) and a concentration of 400ml / L of H 3 PO 4 (85%) The mixed solution that forms is processed 50s, washes again;

...

Embodiment 3

[0040] Weigh the following raw materials according to mass percentage: Zn: 8.6%, Mg: 3.2%, Cu: 8.6%, Li: 1.6%, Zr: 2.5%, Mn: 2.3%, Sm: 0.9%, and the balance is Al and unavoidable Impurities, and smelting, billet; Extrude the billet at a speed of 10mm / s at 500°C;

[0041] For heat treatment of molded parts, firstly carry out primary solution treatment at 430°C for 1h, then carry out secondary solution treatment at 490°C for 2h; then carry out primary aging treatment at 150°C for 16h, and finally at 200°C Carry out 18h secondary aging treatment;

[0042] Carry out surface cleaning to the cartridge case, firstly treat it with an aqueous solution composed of sodium hydroxide with a concentration of 8g / L and sodium bicarbonate with a concentration of 15g / L at 60°C for 5 minutes, then wash it with water, and then wash it with water at 90°C with a concentration of 360ml / L L of H 2 SO 4 (98%) and a concentration of 450ml / L of H 3 PO 4 (85%) The mixed solution that forms is proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com