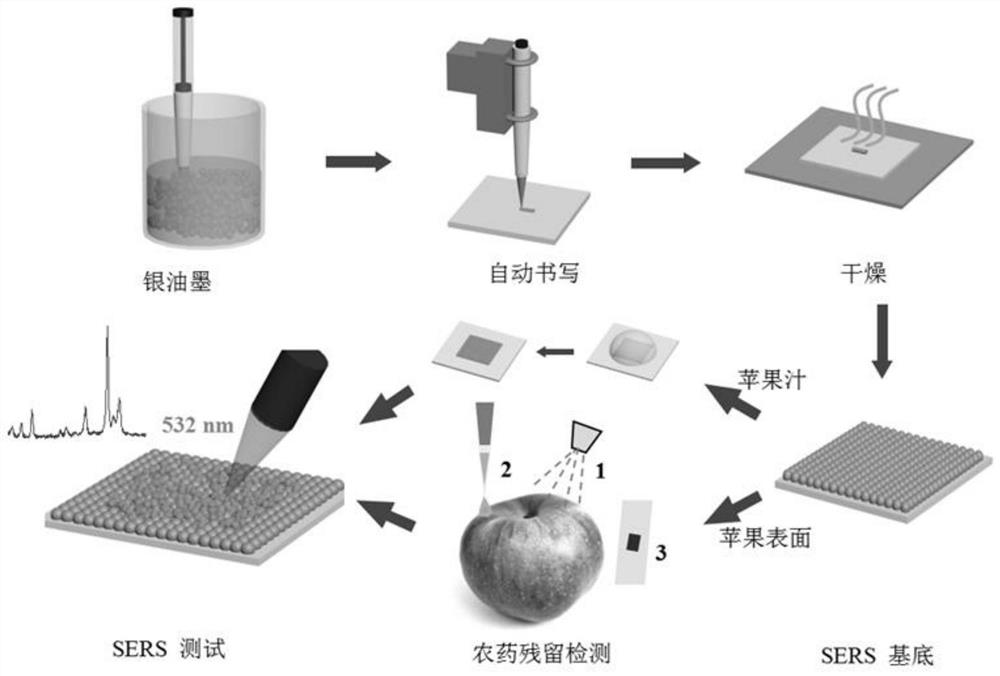

Preparation method and application of automatic writing type SERS substrate

An automatic, substrate technology, applied in the field of analysis and detection, can solve the problems of poor substrate uniformity and repeatability, achieve good uniformity, improve repeatability and uniformity, and controllable writing shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Preparation of silver film / photo paper SERS substrate, the specific steps include:

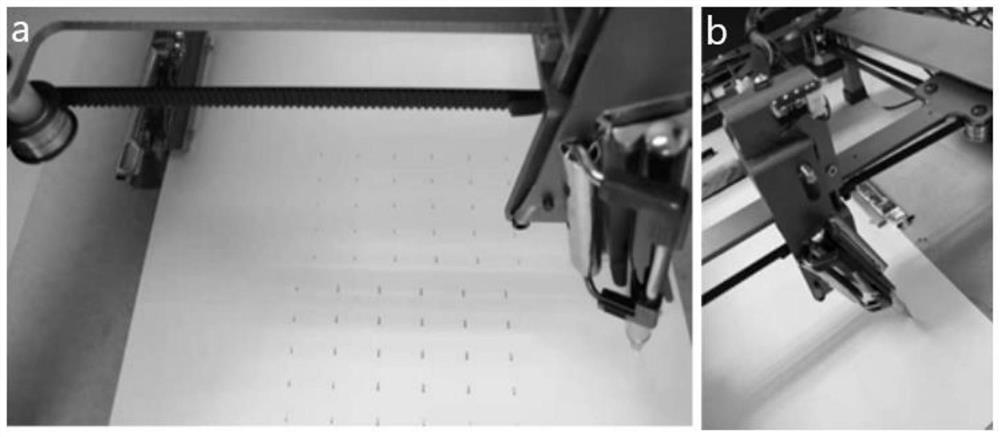

[0062] S1: Use a pen to absorb the ultrasonic silver nano-ink (viscosity coefficient of 100cP), and fix the photo paper on the writing platform; when the ink viscosity coefficient is 100cP, a uniform writing effect can be obtained.

[0063] S2: Set the writing speed of the pen to 12000 μm / s, the height of the pen to 5 mm, and the shape of the writing to be a thin line with a length of 3 mm, distributed in the form of n rows×m columns, where n is 6 and m is 8. The distance between the upper, lower, left, and right sides of the thin lines is 1.5 cm.

[0064] S3: drying the prepared SERS substrate in a vacuum oven. The drying environment is air, and the drying temperature is 110°C. Drying time is 30min.

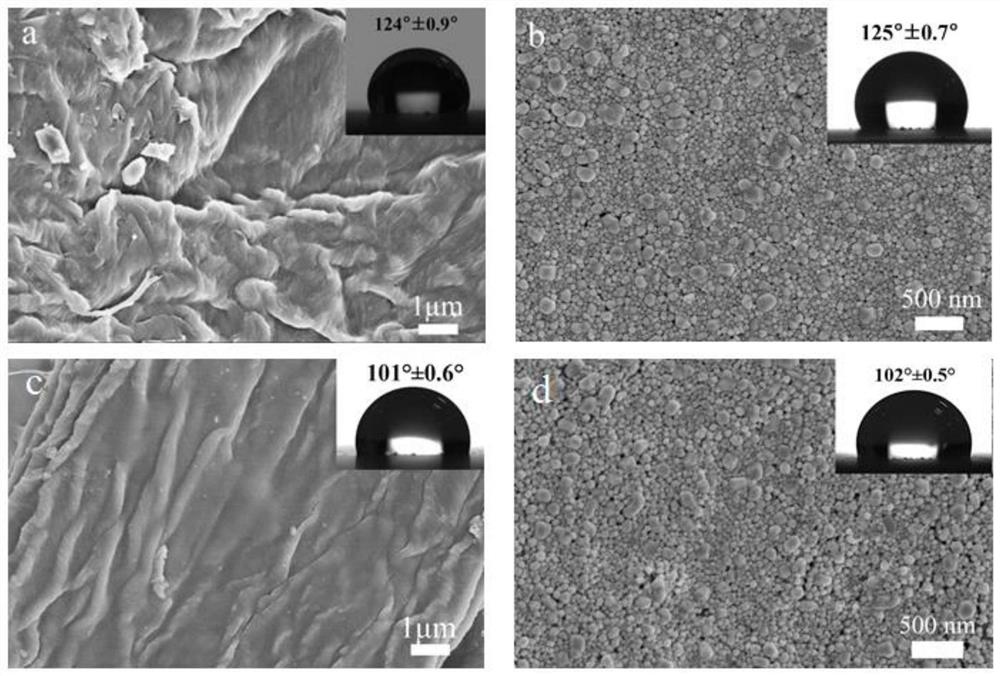

[0065] image 3 a is the field emission SEM image of photo paper, image 3 c is the field emission SEM image of the SERS substrate with photo paper as the substrate.

Embodiment 2

[0067] Preparation of silver film / painting paper SERS substrate, the specific steps include:

[0068] S1: Use a pen to absorb the ultrasonic silver nano-ink (viscosity coefficient of 100cP), and fix the drawing paper on the automatic writing operation platform; when the viscosity coefficient of the ink is 100cP, a uniform writing effect can be obtained.

[0069] S2: Set the writing speed of the pen to 10000 μm / s, the height of the pen to 4 mm, and the shape of the writing to be a thin line of 4 mm long, distributed in the form of n rows×m columns, where n is 6 and m is 8. The distance between the up, down, left, and right sides of the thin lines is 1.5 cm.

[0070] S3: drying the prepared SERS substrate in a vacuum oven. The drying environment is air, and the drying temperature is 100°C. Drying time is 30min.

[0071] image 3 b is the field emission scanning electron microscope image of drawing paper, image 3 d is the field emission SEM image of the SERS substrate with ...

Embodiment 3

[0073] The performance test of SERS substrate includes:

[0074] 1) Sensitivity test:

[0075] Take the SERS substrate prepared in Example 1, take 3 μL of different concentrations of thiram (tetramethylthiuram disulfide, CAS No. 137-26-8) solution and drop it on the SERS substrate, then randomly select points to measure the SERS spectrum, The result is as Figure 4 As shown in a, the minimum detection concentration of SERS substrate is 10 -10 mol / L, the intensity of Raman characteristic peaks decreases with the decrease of concentration, Figure 4 b is the linear fitting diagram of the characteristic peak intensity and concentration, from the graph we know that the characteristic peaks are 556, 1142, 1377cm -1 The linear correlation coefficients with concentration were 0.9490, 0.9303, 0.9956, respectively.

[0076] Take the SERS substrate prepared in Example 2, take 3 μL of different concentrations of malachite green solution and drop it on the SERS substrate, randomly sel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com