Electrolyte for high voltage bolt capacitor and preparation method thereof

An electrolyte and capacitor technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problem of high cost, achieve stable performance, reduce equipment size, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] After mixing polyvinyl alcohol with an amide structure, ethylene glycol, water and boric acid, the reaction was stirred at 160° C. for 3 h to obtain a flash fire elevating agent.

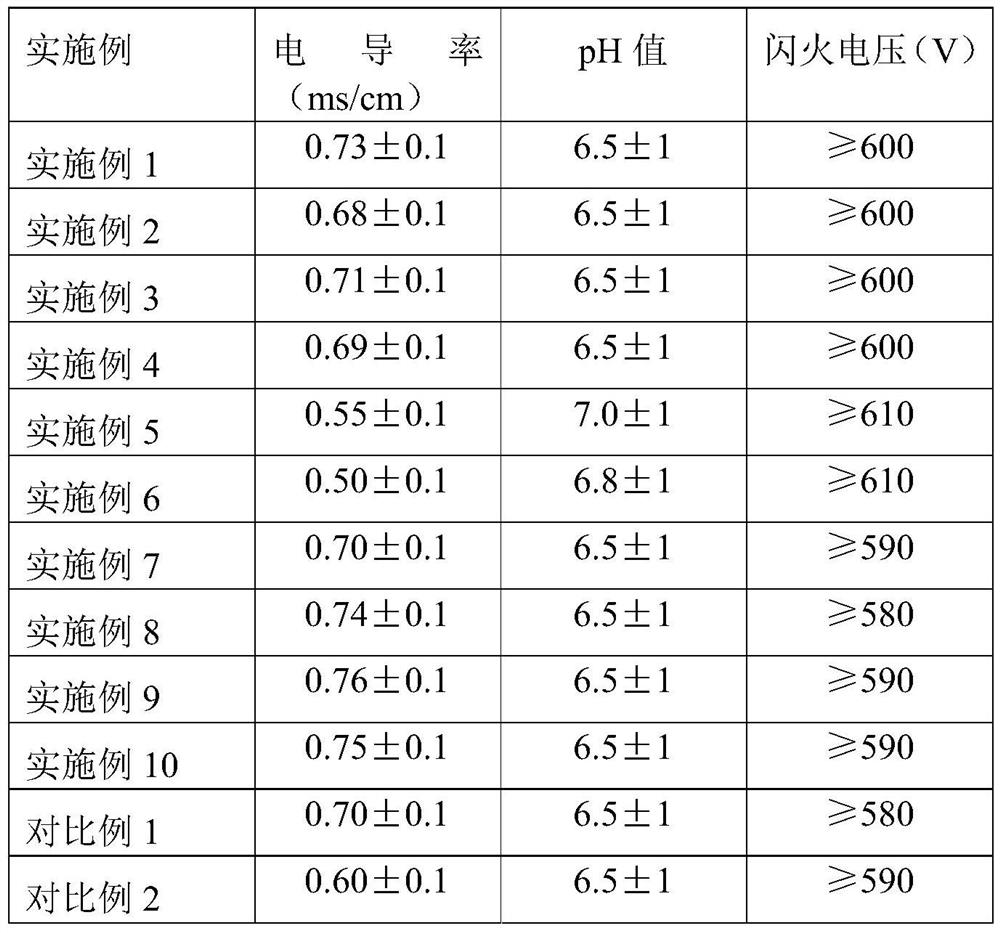

[0026] After mixing the main solvent and auxiliary solvent, heat to 140 °C, add flash fire enhancer for 60 nin, then cool down to 110 °C, add main solute and auxiliary solute for 60 nin, then cool to 90 °C, add hydrogen remover for 30 nin. After the preparation is completed, it is cooled to below 60° C. to obtain an electrolyte solution for a high-voltage capacitor. By changing the types and parts by weight of each component, Examples 1-4 were obtained. The specific types of each component of the electrolyte and the added weight parts are shown in Table 1.

[0027] Among them, polymeric carboxylic acid ammonium salt, 8,13-dimethyl-8,12-diene-eicosadicarboxylate ammonium salt, polyvinyl alcohol with amide structure and common polyvinyl alcohol were all purchased from Wuhan Haispring Technolog...

Embodiment 5

[0039] Example 5 did not add polymeric carboxylate ammonium salt, Example 6 did not add 8,13-dimethyl-8,12-diene-eicosodicarboxylate ammonium salt, the conductivity of the obtained electrolyte decreased, and flash fire occurred. Voltage rises.

Embodiment 7

[0040] In Example 7, ordinary polyvinyl alcohol was used instead of polyvinyl alcohol with an amide structure, and the conductivity of the obtained electrolyte was basically the same as that in Examples 1 to 4, and the flash voltage was reduced.

[0041] In Examples 8-10, the reaction temperature was changed, the conductivity of the electrolyte was increased, and the flash voltage was decreased. Conductivity and flash voltage are the main performance parameters of electrolyte, but in general, there is an inverse relationship between conductivity and flash voltage. When the electrical conductivity is high, the flash fire voltage will decrease accordingly; while increasing the flash fire voltage, the electrical conductivity will decrease. The conductivity affects the loss of the product, and the high conductivity electrolyte can reduce the loss of the capacitor and improve the ability to withstand ripple current. If it has a higher flash voltage, the stability of the electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com