Silicon-carbon composite negative electrode material and preparation method thereof, electrode and secondary battery

A negative electrode material, silicon carbon composite technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as poor electrochemical performance, and achieve the effects of improving performance stability, alleviating volume expansion effect, and excellent charge-discharge efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

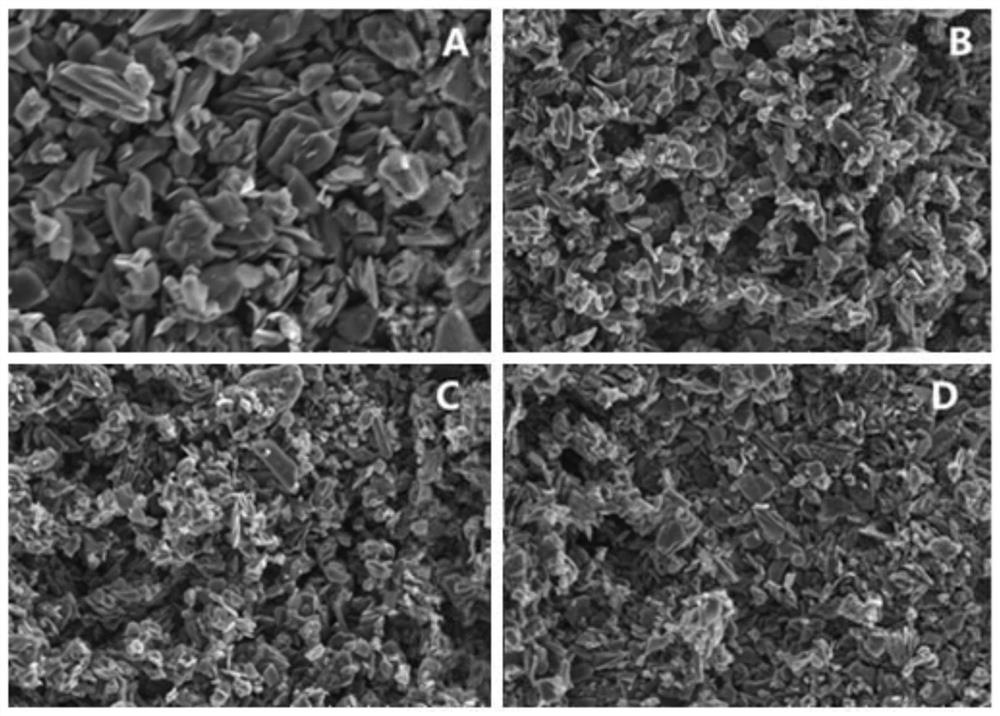

Image

Examples

preparation example Construction

[0035] A method for preparing a silicon-carbon composite negative electrode material, comprising the following steps:

[0036] S01, conducting mixed ball milling of conductive carbon and nano-silicon to obtain a silicon / carbon composite;

[0037] S02. Mixing the silicon / carbon composite and soft carbon to obtain a precursor;

[0038] S03. Calcining the precursor in an inert gas atmosphere to obtain a silicon-carbon composite negative electrode material with a core-shell structure;

[0039] Wherein, based on the total weight of the conductive carbon, the nano-silicon and the soft carbon as 100%, the weight percentage of the nano-silicon is 2%-20%, and the weight percentage of the soft carbon 2%-4%.

[0040] The preparation method of the silicon-carbon composite negative electrode material provided by the embodiment of the present invention, on the one hand, conducts mixed ball milling of conductive carbon and nano-silicon, so that the nano-silicon can be evenly embedded in the ...

Embodiment 1

[0071] This embodiment provides a silicon-carbon composite negative electrode material, the preparation method of which comprises the following steps:

[0072] (1) Weigh 2 parts of nano-silicon, 2 parts of pitch and 96 parts of artificial graphite (produced by Shanghai Shanshan, the specification is FS-1); the purity of nano-silicon is 99.9%, and the particle size is 20nm;

[0073] (2) Add nano-silicon to graphite, mix evenly, and ball mill in a planetary ball mill (produced in Shanghai, specification is PM-2A), set the ball milling speed to 250rmp, the ball milling time to 1.5h, and the ball-to-material ratio to 12:1, to obtain Silicon / carbon composite;

[0074] (3) Place the silicon / carbon composite in a VC mixer (produced in Shanghai, specification V150), add asphalt, and perform mixing until it is evenly mixed to obtain a precursor;

[0075] (4) Under a nitrogen atmosphere, calcinate the precursor in a high-temperature furnace at 850°C (SG1400 produced in Shanghai) for 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com