Gaseous iodine adsorption material with foamed nickel as framework as well as preparation method and application thereof

A foam nickel, iodine adsorption technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problem of insufficient adsorption, the risk of iodine migration, and the serious physical adsorption of iodine adsorption materials. and other problems, to achieve the effect of improving adsorption capacity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

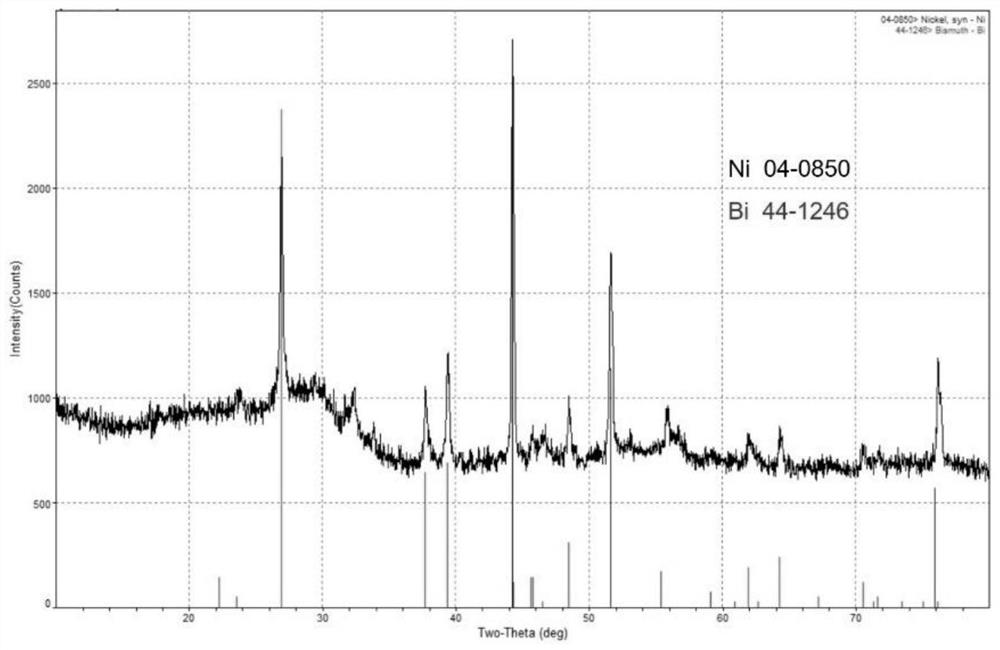

[0042] Preparation of adsorption material with nickel foam as the skeleton and bismuth as the active site:

[0043] (1) Cutting preparation of nickel foam: Cut the purchased nickel foam with a thickness of 0.5mm to 2.5×2cm 2 size, washed with ethanol ultrasonically and dried;

[0044] (2) Configuration of bismuth salt solution: Weigh 0.7275g of bismuth nitrate pentahydrate, dissolve in the mixed solution of ethanol and ethylene glycol (the volume ratio of ethanol to ethylene glycol is 1:1, each is 7.5mL), stir 30min;

[0045] (3) Solvothermal reaction: the nickel foam obtained in step (1) and the bismuth salt solution obtained in step (2) are placed in a 25ml reaction kettle together, and after standing for half an hour, react at 200°C for 12h;

[0046] (4) After the reaction is finished and the reaction is naturally lowered to room temperature, it is taken out with tweezers and washed several times, and dried to obtain the iodine adsorption material with nickel foam as the ...

Embodiment 2

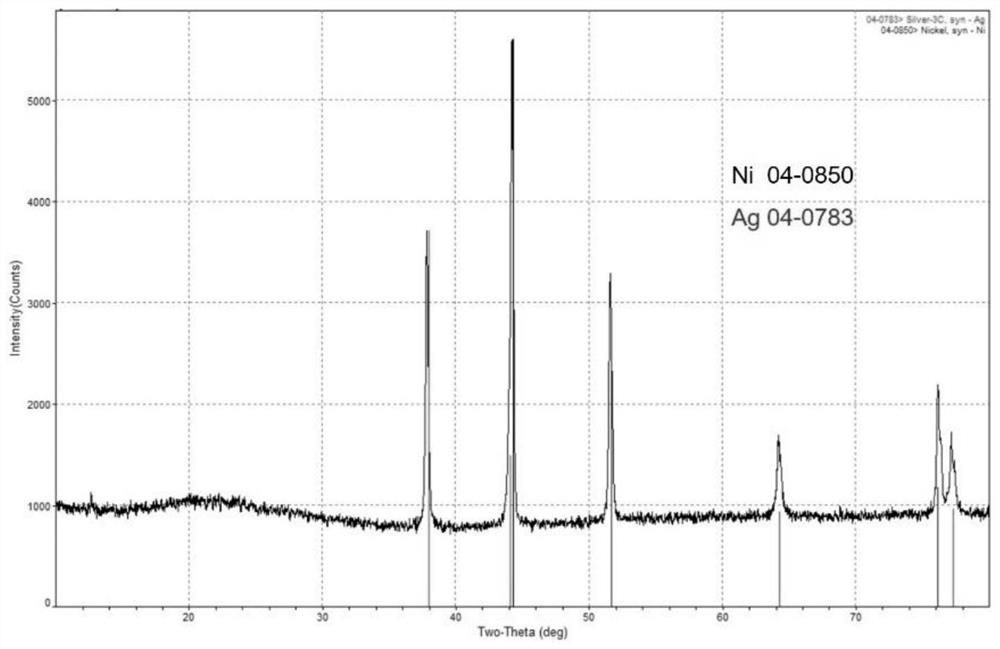

[0049] This embodiment is an iodine adsorption material with nickel foam as the skeleton and silver as the active site. Compared with Example 1, except that the bismuth nitrate pentahydrate in step (2) is replaced by 0.7275g silver nitrate, other steps unchanged, an iodine adsorption material with nickel foam as the skeleton and silver active sites was obtained.

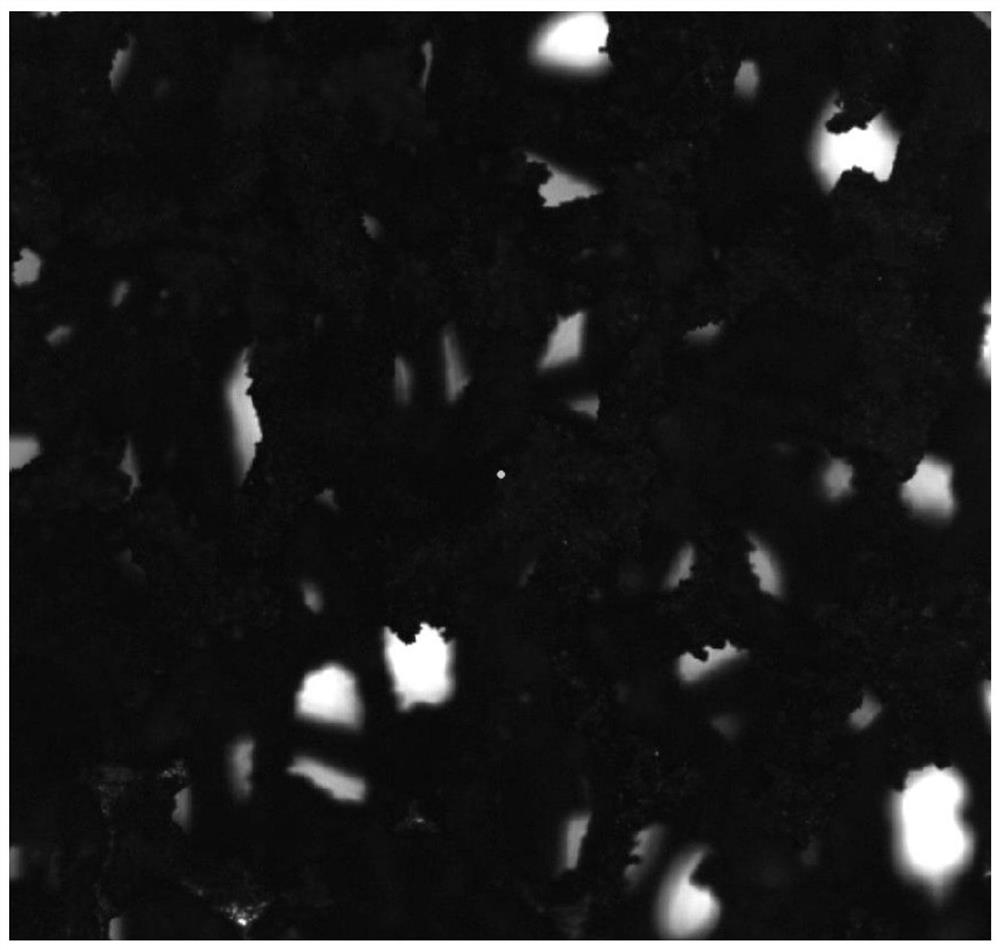

[0050] The adsorption material of embodiment 2 is characterized, and XRD collection of lines is as follows figure 2 As shown, all the diffraction peaks can be attributed to the simple substance of silver (PDF No.04-0783) and the nickel substance of the nickel foam framework (PDF No.04-0850), indicating that under the solvothermal reaction, the silver ions are all reduced to Silver is single substance and successfully loaded onto the nickel framework. Optical microscopy results such as Figure 4 As shown, it can be seen that a layer of silver particles has been firmly wrapped on the surface of the nickel foam, form...

Embodiment 3

[0052] According to the preparation process of Example 1, the solvent in step (2) was replaced with a mixed solution with a volume ratio of ethanol and ethylene glycol of 1:2 and 2:1, respectively, to prepare an adsorption material whose active site was bismuth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com