Method for retarding inhibition of palmitic acid on anaerobic digestion methane production of waste grease

An anaerobic digestion, palmitic acid technology, applied in chemical instruments and methods, waste fuel, water treatment parameter control, etc., can solve the problems of reducing the rate of methane production, hindering the transfer of nutrients and electrons, and washing out sludge by flotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

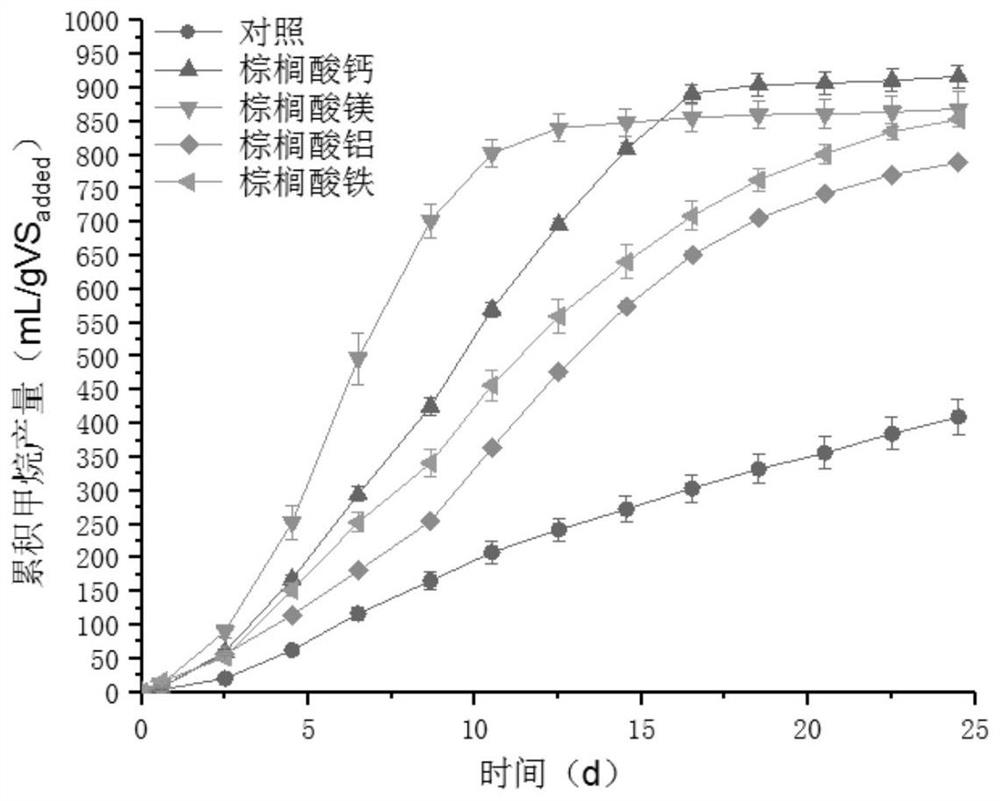

[0021] The present embodiment provides a method for alleviating the inhibition of palmitic acid on methane production from anaerobic digestion of waste oil and fat, which specifically includes the following steps:

[0022] In this example, calcium palmitate was used as the reaction substrate, and three groups of anaerobic digestion flasks with a total volume of 150 mL were set up, and three parallel samples were set in each group, namely the calcium palmitate group. In the initial stage of the reaction, according to the ratio of substrate to inoculum of 1:1 (gVS / gVS), 20 mL of inoculated sludge was added to each group of anaerobic digestion flasks, and then the corresponding amount of calcium palmitate was added, respectively Nitrogen was passed through the anaerobic digestion bottle for 5 minutes, and the air was exhausted to maintain anaerobic conditions.

[0023] All anaerobic digestion flasks were subjected to anaerobic digestion at a temperature of 35-37 °C and a rotation...

Embodiment 2

[0025] The present embodiment provides a method for alleviating the inhibition of palmitic acid on methane production from anaerobic digestion of waste oil and fat, which specifically includes the following steps:

[0026] In this example, magnesium palmitate was used as the reaction substrate, and three groups of anaerobic digestion flasks with a total volume of 150 mL were set up, and three parallel samples were set in each group, namely the magnesium palmitate group. In the initial stage of the reaction, according to the ratio of substrate to inoculum of 1:1 (gVS / gVS), 20 mL of inoculated sludge was added to each group of anaerobic digestion flasks, and then the corresponding amount of magnesium palmitate was added, respectively Nitrogen was passed through the anaerobic digestion bottle for 5 minutes, and the air was exhausted to maintain anaerobic conditions.

[0027] All anaerobic digestion flasks were subjected to anaerobic digestion at a temperature of 35-37 °C and a ro...

Embodiment 3

[0029] The present embodiment provides a method for alleviating the inhibition of palmitic acid on methane production from anaerobic digestion of waste oil and fat, which specifically includes the following steps:

[0030] In this example, aluminum palmitate was used as the reaction substrate, and three groups of anaerobic digestion flasks with a total volume of 150 mL were set up, and three parallel samples were set in each group, namely the aluminum palmitate group. In the initial stage of the reaction, according to the ratio of substrate to inoculum of 1:1 (gVS / gVS), 20 mL of inoculated sludge was added to each group of anaerobic digestion flasks, and then the corresponding amount of aluminum palmitate was added, respectively Nitrogen was passed through the anaerobic digestion bottle for 5 minutes, and the air was exhausted to maintain anaerobic conditions.

[0031] All anaerobic digestion flasks were subjected to anaerobic digestion at a temperature of 35-37 °C and a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com