Halogen-free flame-retardant polypropylene compound suitable for new energy automobile as well as application and preparation method of halogen-free flame-retardant polypropylene compound

A technology for flame-retardant polypropylene and new energy vehicles, which is applied in the field of high-molecular polymers, can solve the problems of poor thermal stability of phosphorus-nitrogen-type halogen-free intumescent flame retardants, decreased flame-retardant properties of materials, and poor hydrolytic stability. Excellent heat resistance and hydrolysis resistance, improve poor water resistance, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

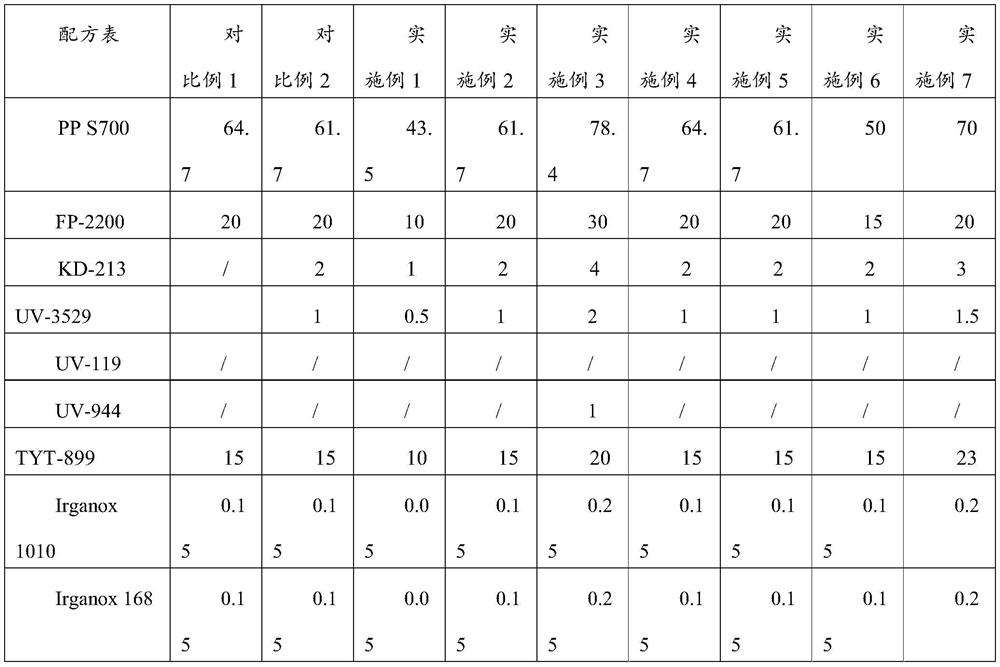

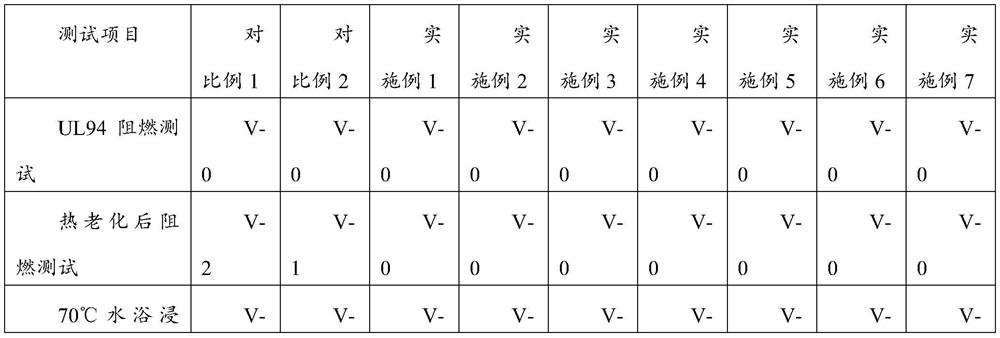

[0036] The halogen-free flame-retardant polypropylene compound of this embodiment is composed of the components in Table 1 (Example 1), and the preparation method of the halogen-free flame-retardant polypropylene compound is as follows:

[0037] (1) Mix 0.5 parts by weight of hindered amine light stabilizer UV-3529, 1 part by weight of epoxy resin KD-213, 10 parts by weight of intumescent halogen-free flame retardant FP-2200 and 10 parts by weight of polypropylene PP S700 in banburying Fully banbury in the machine for 30 minutes to ensure that the surface of the halogen-free flame retardant is fully coated with epoxy resin and hindered amine light stabilizer, so as to improve the thermal stability and hydrolysis resistance of the halogen-free flame retardant. A single-screw extruder connected in series with an internal mixer is extruded and granulated to obtain flame-retardant masterbatches.

[0038] (2) Combine the flame retardant masterbatch produced by the first step intern...

Embodiment 2

[0040] The halogen-free flame-retardant polypropylene compound of this embodiment is composed of the components in Table 1 (Example 2), and the preparation method of the halogen-free flame-retardant polypropylene compound is as follows:

[0041](1) 1 part by weight of hindered amine light stabilizer UV-3529, 2 parts by weight of epoxy resin KD-213, 20 parts by weight of intumescent halogen-free flame retardant FP-2200 and 5 parts by weight of polypropylene PP S700 in banburying Fully banbury in the machine for 30 minutes to ensure that the surface of the halogen-free flame retardant is fully coated with epoxy resin and hindered amine light stabilizer, so as to improve the thermal stability and hydrolysis resistance of the halogen-free flame retardant. A single-screw extruder connected in series with an internal mixer is extruded and granulated to obtain flame-retardant masterbatches.

[0042] (2) The flame retardant masterbatch produced by the first step internal mixer interna...

Embodiment 3

[0044] The halogen-free flame-retardant polypropylene compound of this embodiment is composed of the components in Table 1 (Example 3), and the preparation method of the halogen-free flame-retardant polypropylene compound is as follows:

[0045] (1) 2 parts by weight of hindered amine light stabilizer UV-3529, 4 parts by weight of epoxy resin KD-213, 30 parts by weight of intumescent halogen-free flame retardant FP-2200 and 15 parts by weight of polypropylene PP S700 in banburying Fully banbury in the machine for 30 minutes to ensure that the surface of the halogen-free flame retardant is fully coated with epoxy resin and hindered amine light stabilizer, so as to improve the thermal stability and hydrolysis resistance of the halogen-free flame retardant. A single-screw extruder connected in series with an internal mixer is extruded and granulated to obtain flame-retardant masterbatches.

[0046] (2) The flame-retardant masterbatch produced by the first step of internal mixer m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com