Compression, degassing and carbonization method and device for solid waste, and system comprising device

A technology of degassing carbonization and degassing chamber, which is applied in the direction of presses, special forms of dry distillation, petroleum industry, etc. It can solve the inconvenience of fine classification or centralized treatment and disposal, the difficulty of finding common points in the geometric properties of bulk materials, and the complexity of collection and treatment processes and other issues, to achieve the effect of deep reduction, promotion of comprehensive energy efficiency and improvement of comprehensive efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

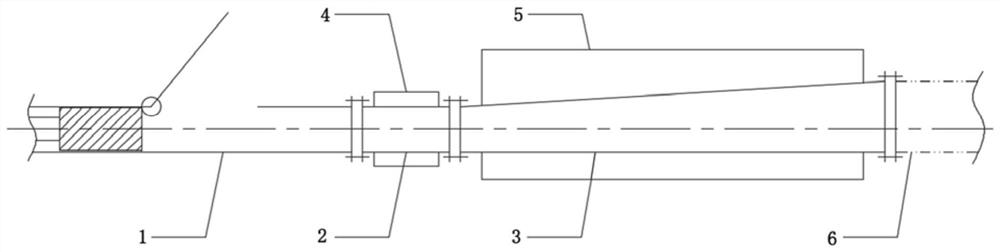

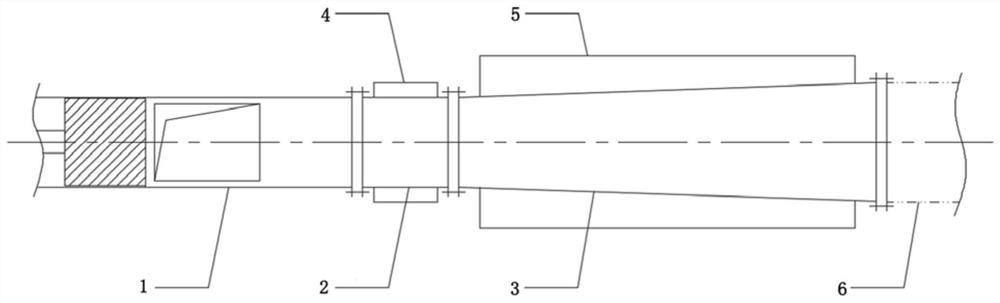

[0031] Such as figure 1 , figure 2 As shown, a compression degassing carbonization device includes: a high-pressure compression device 1 , a material sealing chamber 2 and a degassing chamber 3 .

[0032] The high-pressure compression equipment, the material sealing chamber and the degassing chamber are sealed in sequence and installed on the same central axis. The high-pressure compression equipment is used for multi-stage, high-pressure, continuous compression molding of solid waste and bulk materials, as well as continuous discharge and material sealing. The chamber is filled with compressed solid waste material to form a natural isolation between the high-pressure compression equipment and the degassing chamber, so that the inlet of the degassing chamber is isolated from oxygen (air). The degassing chamber is used for drying, anaerobic pyrolysis and carbonization of solid waste blocks, and finally converts solid waste blocks into carbon powder and pyrolysis gas.

[0033...

Embodiment 2

[0045] A high-temperature melting gasification system is used for high-temperature melting treatment of solid waste and hazardous waste, including the solid waste compression degassing and carbonization device in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com