System and method for preparing LNG and co-producing hydrogen by deeply purifying coke oven gas

A coke oven gas and deep purification technology, which is applied in combustible gas purification, chemical instruments and methods, combustible gas purification/transformation, etc., can solve the problems of affecting the stable operation of the system, increasing operating costs, and low hydrogen yield, and achieves the goal of using The effect of prolonging life, reducing investment, and making acid with high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below with reference to the accompanying drawings and examples.

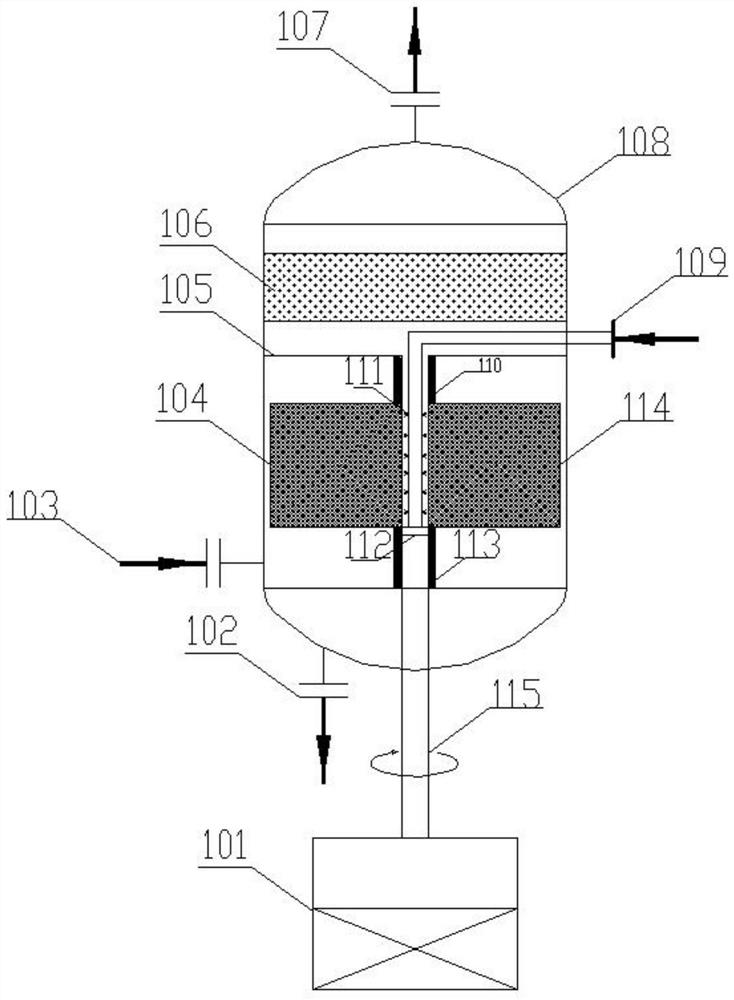

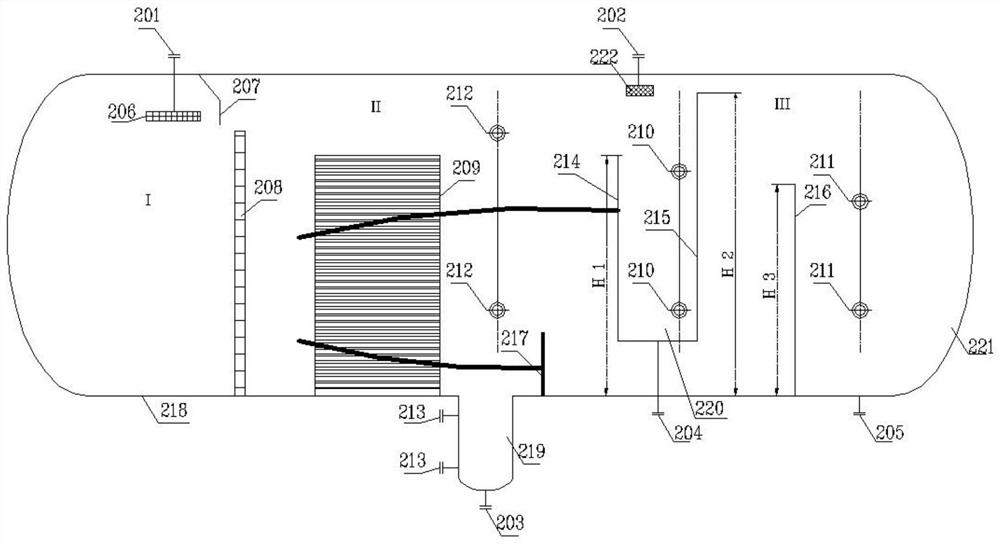

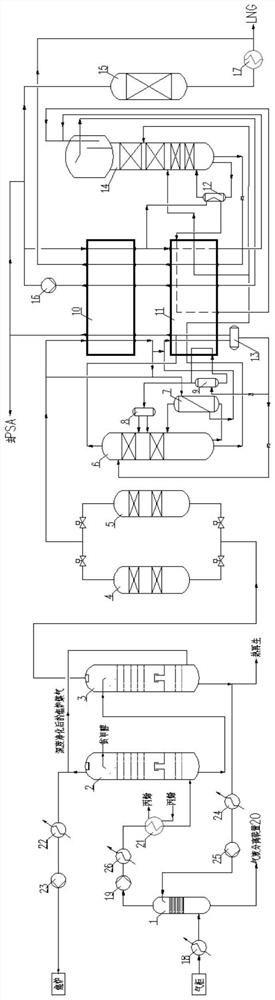

[0040] Such as figure 1 As shown, the embodiment of the present invention provides a system of coke oven gas depth purification, LNG joint hydrogen, including pre-washing tower 1, desulfurization tower 2, decarbonate tower 3, first absorbent tower 4, second absorbent tower 5, stripper 6, first reboiler 7, first gas liquid separator 8, second gas liquid separator 9, first cold tank 10, second cold tank 11, second reboiler 12, The three gas separator 13, the separation column 14, and the methane tube 15, wherein the preamble tower 1 is an overweight rotating device, wherein the gas cabinet is inlet with the first heat exchanger 18 and the lower portion of the pre-washed tower 1 103 is connected, the liquid phase outlet 102 of the pre-washing tower 1 is connected to the gas-liquid separation device 20, the gas outlet 107 at the top of the pre-washing towe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com