Composite dephosphorizing agent for tapping after furnace, preparation method and application

A composite dephosphorization agent and post-furnace technology, applied in the field of metallurgy, can solve the problems of unconsidered, limited contact area between dephosphorization flux and molten steel, etc., and achieve the effects of short reaction time, obvious phosphorus fixation effect, and obvious use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

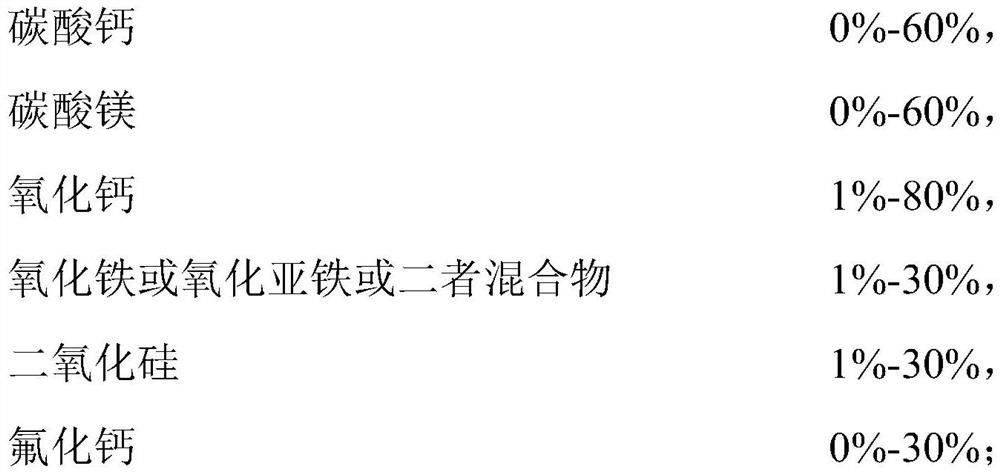

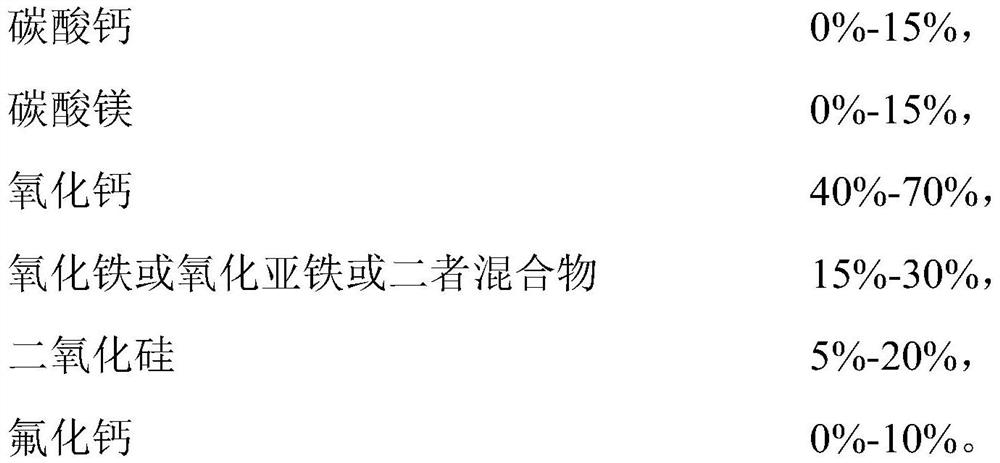

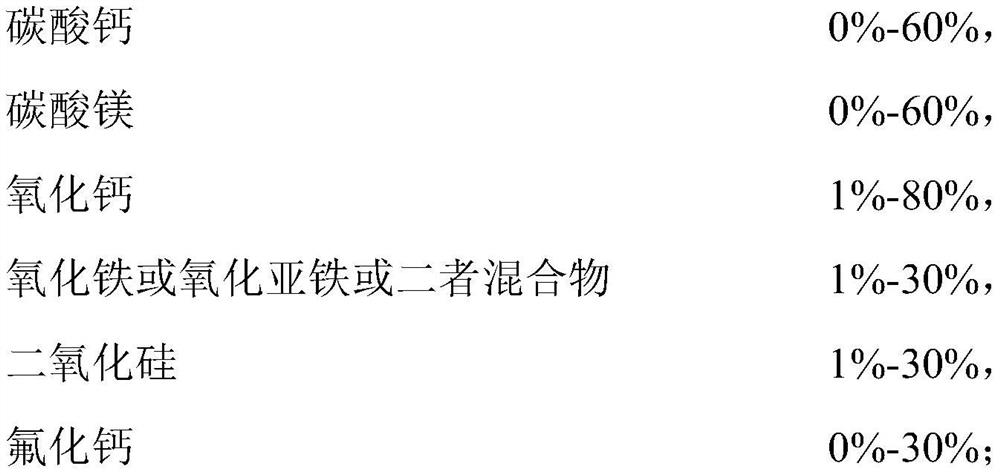

[0032] Described sintering dephosphorization powder takes CaO 40kg according to formula ratio, SiO 2 10kg, Fe 2 o 3 10kg, CaF 2 5kg, put into a crusher for crushing and grinding to a powder with a particle size of 1mm. Put the above-mentioned powder and 5 kg of binder into a mixer for thorough mixing, and the mixing time is 2 hours. After fully mixing, use a sintering machine to sinter at a temperature of 800°C for 6 hours. The binder is prepared by mixing 30% clay, 30% water glass and 40% bentonite according to the formula. Put the sintered particles into the crushing and grinding machine again for secondary crushing and grinding. The grinding time is 2.5 hours to obtain a powder with a particle size of less than 2 mm. Put the secondary crushed powder into a dryer for drying, the drying temperature is 100°C, and the drying time is 7 hours. After cooling to room temperature, pack it in bags, each bag is 20kg, and use it within one month. Adding 4kg / ton of this produc...

Embodiment 2

[0034] The formula of the mechanical mixing powder dephosphorization agent is to take CaCO 3 20kg, CaO 50kg, SiO 2 15kg and 15kg of FeO were prepared, put into a crusher for fully crushing and mixing, the crushing and mixing time was 2 hours, and the powder was screened by sieving to obtain a dephosphorization agent powder with a particle size of 1.5mm. Use a dryer to dry the above dephosphorizing agent powder at a temperature of 120°C for 6 hours. After cooling to room temperature, pack it into bags of 30kg each and use it within one month. Adding 5kg / ton of this product in the tapping process after the furnace can reduce the phosphorus content in molten steel from 0.014% to 0.0045%.

Embodiment 3

[0036] The formula of the mechanical mixing powder dephosphorization agent is to take CaCO 3 10kg, MgCO 3 10kg, CaO 50kg, SiO 2 15kg, Fe 2 o 3 15kg for preparation, put into a crusher for fully crushing and mixing, the crushing and mixing time is 1 hour, and the powder is screened by sieving to obtain a dephosphorizing agent powder with a particle size of 2mm. Use a dryer to dry the above-mentioned dephosphorizing agent powder at a temperature of 150°C for 8 hours. After cooling to room temperature, pack it in bags of 40kg each and use it within one month. Adding 4.5kg / ton of this product in the tapping process after the furnace can reduce the phosphorus content in molten steel from 0.013% to 0.005%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com