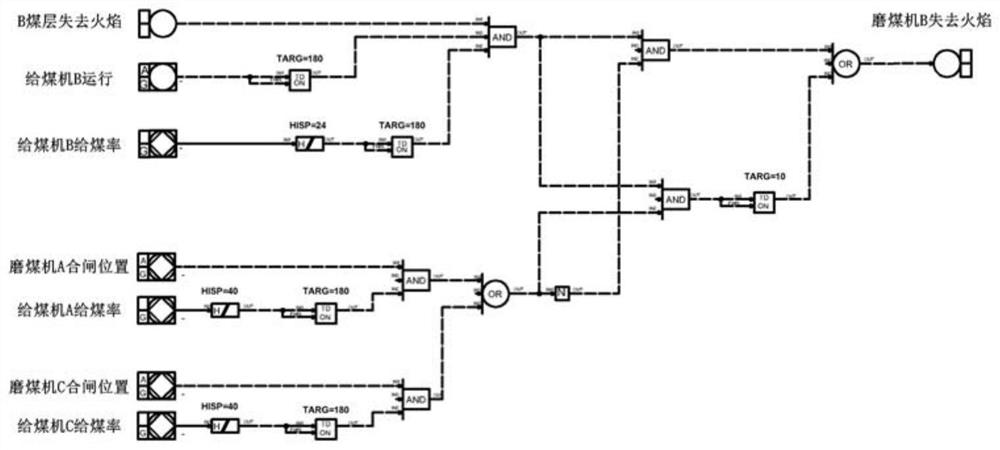

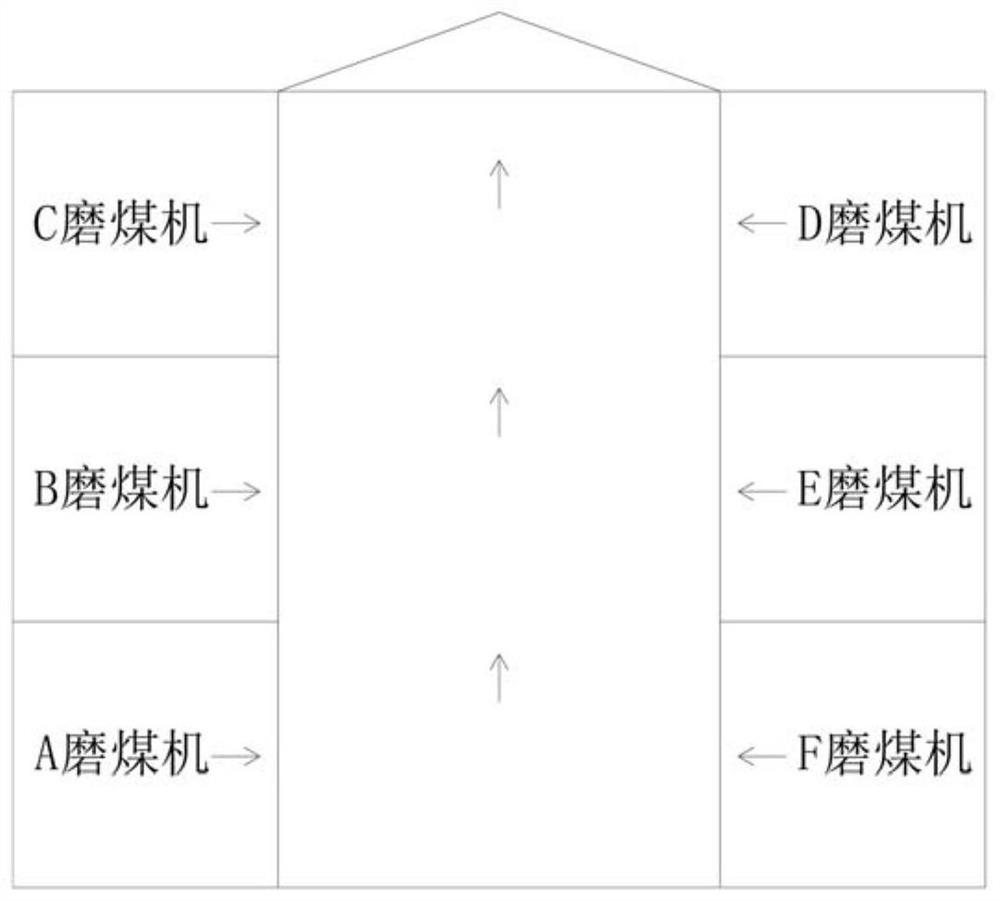

Boiler critical flame protection maloperation prevention regulation and control system

A control system and anti-misoperation technology, applied in the direction of combustion control, combustion method, lighting and heating equipment, etc., can solve problems such as large energy and time consumption, misoperation, power plant loss, etc., to reduce consumption and improve judgment accuracy , The effect of reducing the risk of tripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments. The drawings are for exemplary description, which is merely a schematic diagram, rather than the experiment, and is not to be understood to be in this patent; in order to better illustrate the embodiments of the invention, there will be omitted, Enlarge or shrink does not represent the size of the actual product; some well-known structures and descriptions thereof may be understood in the drawings in the drawings.

[0025] The same or similar components in the drawings of the embodiments correspond to the same or similar components; in the description of the present invention, it is to be understood that if there is a term "upper", "lower", "left", "right" The orientation or positional relationship of the indication is based on the orientation or positional relationship shown in the drawings, is merely described in order to facilitate the description of the present invention and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com