Preparation method of metal monatomic catalyst, metal monatomic catalyst and application

A catalyst and metal technology, applied in catalyst activation/preparation, preparation of organic compounds, preparation of amino compounds, etc., can solve the problems of metal single-atom catalysts, such as poor dispersion and high thermal stability, high preparation cost, and poor universality. Good application prospects, precise and controllable preparation, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

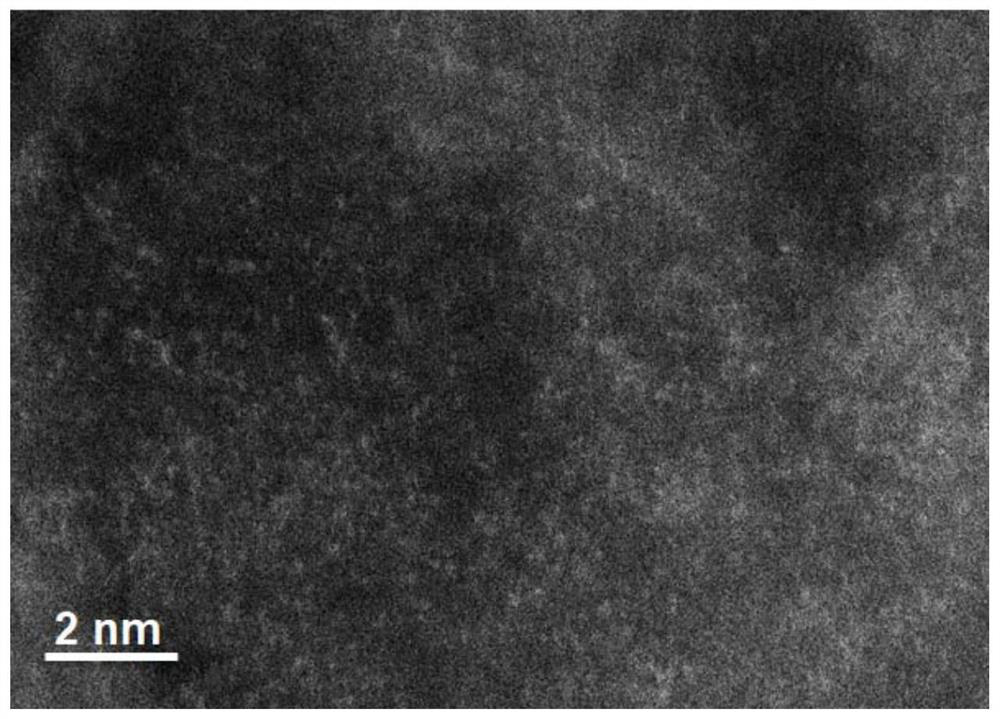

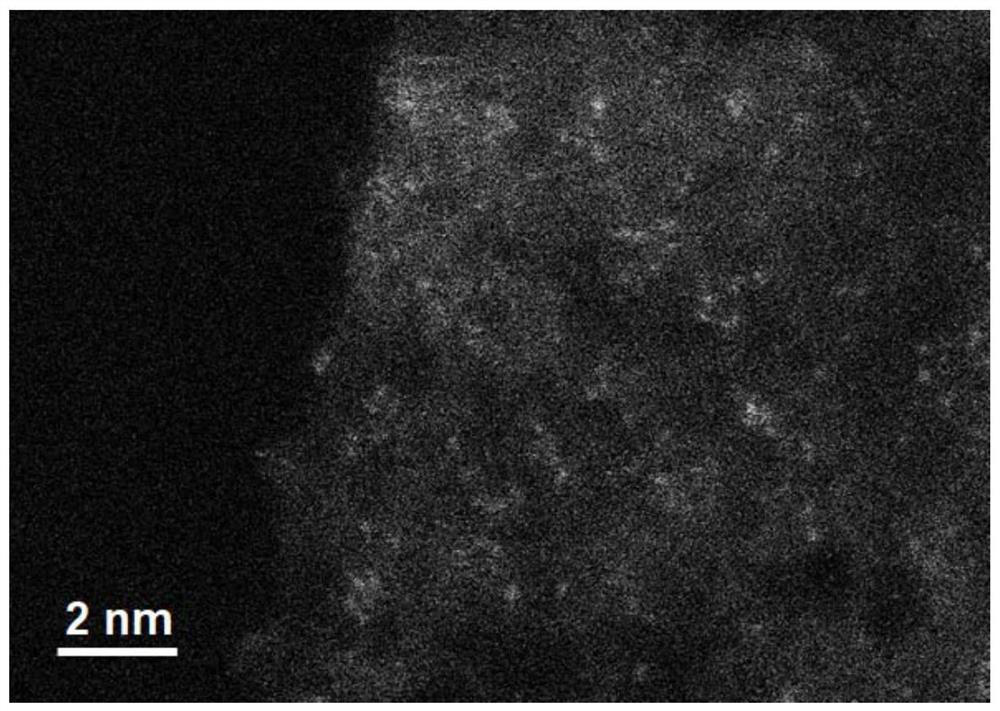

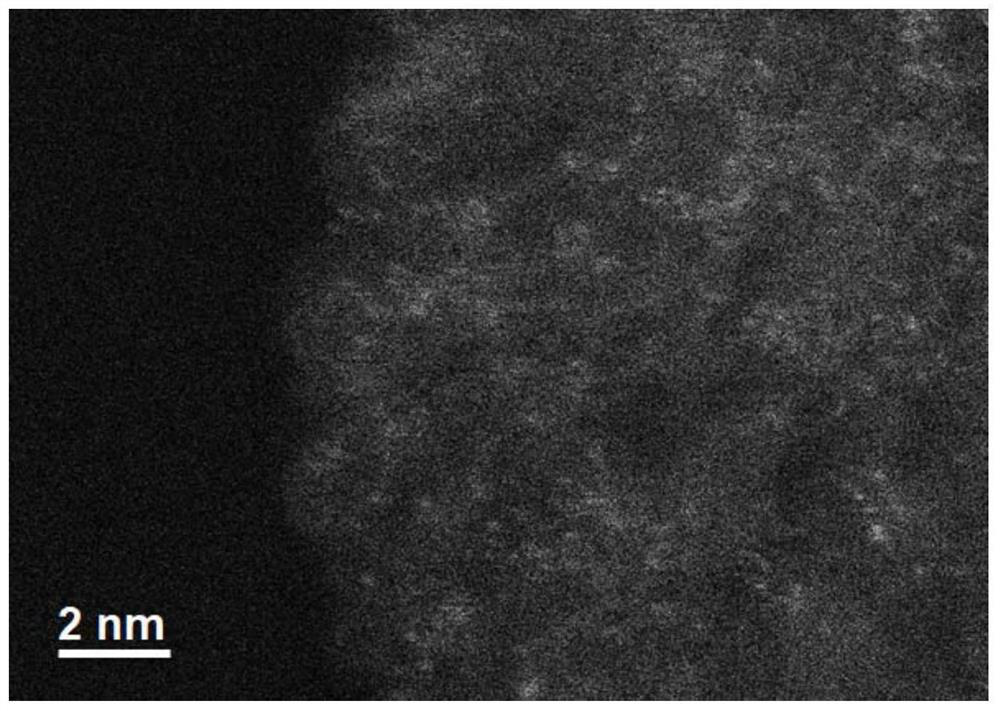

Image

Examples

preparation example Construction

[0054] According to a first aspect of the present invention, a method for preparing a metal single-atom catalyst is provided, comprising the following steps:

[0055] (a) providing a hydroxylation template;

[0056] Mixing the hydroxylated template, coupling agent and solvent A, reacting and separating to obtain the first template with surface functionalization;

[0057] (b) mixing and separating the first template, the metal precursor and the solvent B to obtain a second template with the metal precursor loaded on the surface;

[0058] (c) mixing the second template with a carbon source, calcining under a protective atmosphere, and detemplating the obtained calcined material to obtain a metal single-atom catalyst; wherein, the carbon source has a penetration of 30-160 / 0.1mm.

[0059] Specifically, in step (a), the hydroxylated template is modified with a coupling agent, and the coupling agent is grafted onto the hydroxylated template to form a surface-functionalized first te...

Embodiment approach

[0068] As an optional embodiment of the present invention, in step (a), the preparation method of the hydroxylated template comprises the following steps:

[0069] The template, basic reagent and solvent C are mixed and separated to obtain the hydroxylated template.

[0070] As a morphology regulator, the template can regulate the morphology of metal single-atom catalysts. The template can be removed by high-temperature pyrolysis or acid-base washing in the later stage.

[0071] Treating the surface of the template with an alkaline reagent can increase the hydroxyl density on the surface of the template, which is conducive to grafting more coupling agents, thereby effectively increasing the loading of metal single atoms (metal precursors). The hydroxyl content on the surface of the hydroxylated template can be flexibly adjusted by the amount of basic reagent used.

[0072] As an optional embodiment of the present invention, the template includes metal oxide and / or metal hydr...

Embodiment 1

[0117] This embodiment provides a method for preparing a Co-N-C metal single-atom catalyst, comprising the following steps:

[0118] (a) Provide hydroxylated template: Ultrasonic disperse 5.61g of alkaline reagent (sodium hydroxide) in 200mL of absolute ethanol, add 2g of template (flaky magnesium oxide), ultrasonically disperse for 1h, then stir at 25°C for 6h, The precipitate was filtered and washed with absolute ethanol, and freeze-dried at minus 55°C for 24 hours to obtain a hydroxylated template (hydroxylated magnesium oxide);

[0119] Disperse 1.0g of hydroxylated template in 200mL of solvent A (absolute ethanol), ultrasonically disperse for 1h, slowly add 0.5mL of coupling agent (3-aminopropyltriethoxysilane) dropwise, and vigorously stir the reaction at 60°C 6h, the precipitate was filtered and washed with absolute ethanol, and freeze-dried for 24h to obtain the surface functionalized first template (surface aminated magnesium oxide);

[0120] (b) Weigh 1.0 g of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com