A two-stage stone mill device, oolong matcha production line and its processing technology

A production line and stone grinding technology, applied in the field of tea processing, can solve the problems of short maintenance time, poor color stability and high temperature sensitivity, and achieve the effects of long maintenance time, mild drying effect and improved drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

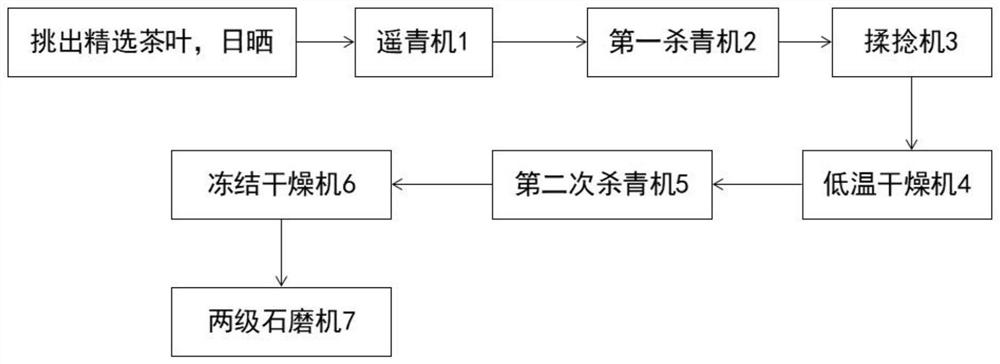

[0134] The processing technology of oolong matcha tea in the present embodiment comprises the following steps:

[0135] Step 1, pick out selected tea leaves from the tea gardens that have been applied with seaweed fertilizer, and sun-dry, the temperature is controlled at 35°C, and the sun-drying time is 80 minutes;

[0136] The second step is to shake the green tea, and the sun-treated tea leaves are subjected to the shaking green treatment, wherein the shaking green treatment time is 4 minutes, the rotating speed of the shaking green machine is 30 r / min, the temperature is controlled at 22° C., and the humidity is 50%;

[0137] Step 3, fixing and rolling, using a two-speed drum-type steam fixing machine, steam pressure 3 kg, temperature 130 ° C, fixing for 40 seconds; the tea leaves after fixing are rapidly cooled and then subjected to rolling treatment, and the rolling machine is pressed for 20 minutes for rolling;

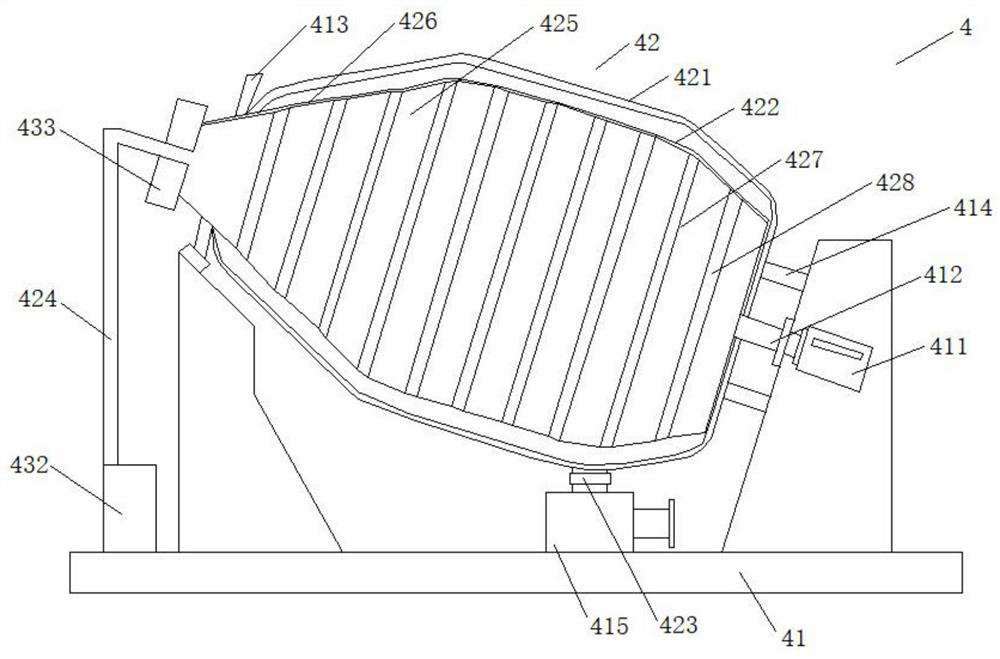

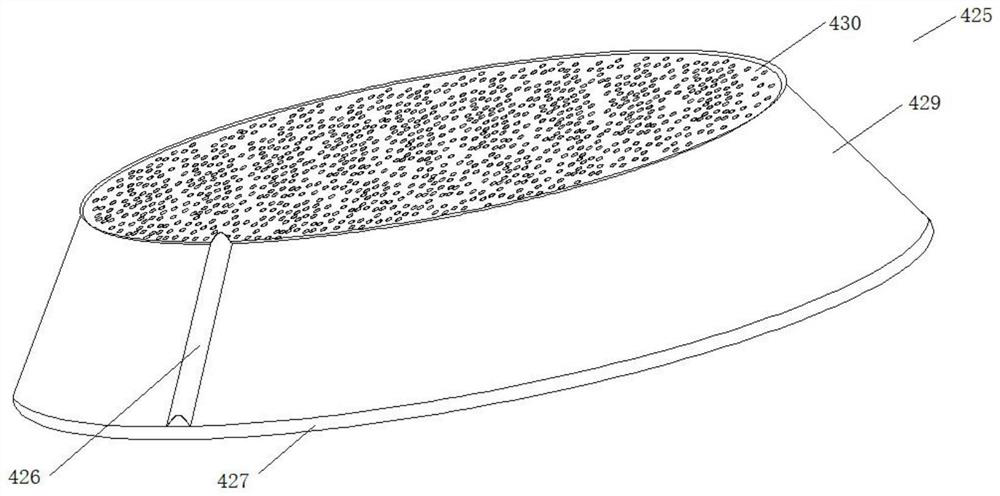

[0138] Step 4, low temperature drying, secondary fixing, d...

Embodiment 2

[0143] The processing technology of oolong matcha tea in the present embodiment comprises the following steps:

[0144] Step 1, pick out selected tea leaves from the tea gardens that have been applied with seaweed fertilizer, and sun-dry, the temperature is controlled at 35°C, and the sun-drying time is 80 minutes;

[0145] The second step is to shake the green tea, and the sun-treated tea leaves are subjected to the shaking green treatment, wherein the shaking green treatment time is 4 minutes, the rotating speed of the shaking green machine is 30 r / min, the temperature is controlled at 22° C., and the humidity is 50%;

[0146] Step 3, fixing and rolling, using a two-speed drum-type steam fixing machine, steam pressure 3 kg, temperature 130 ° C, fixing for 40 seconds; the tea leaves after fixing are rapidly cooled and then subjected to rolling treatment, and the rolling machine is pressed for 20 minutes for rolling;

[0147] Step 4, low temperature drying, secondary fixing, d...

Embodiment 3

[0152] The processing technology of oolong matcha tea in the present embodiment comprises the following steps:

[0153] Step 1, pick out selected tea leaves from the tea gardens that have been applied with seaweed fertilizer, and sun-dry, the temperature is controlled at 35°C, and the sun-drying time is 80 minutes;

[0154] The second step is to shake the green tea, and the sun-treated tea leaves are subjected to the shaking green treatment, wherein the shaking green treatment time is 4 minutes, the rotating speed of the shaking green machine is 30 r / min, the temperature is controlled at 22° C., and the humidity is 50%;

[0155] Step 3, fixing and rolling, using a two-speed drum-type steam fixing machine, steam pressure 3 kg, temperature 130 ° C, fixing for 40 seconds; the tea leaves after fixing are rapidly cooled and then subjected to rolling treatment, and the rolling machine is pressed for 20 minutes for rolling;

[0156] Step 4, low temperature drying, secondary fixing, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com