A collector, a flotation agent and a flotation method for separating copper and molybdenum

A collector and flotation agent technology, which is applied in the field of collectors for the separation of copper and molybdenum, can solve the problems of poor selectivity and large dosage, and achieve improved effect, strong separation and collection, and strong capture absorptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

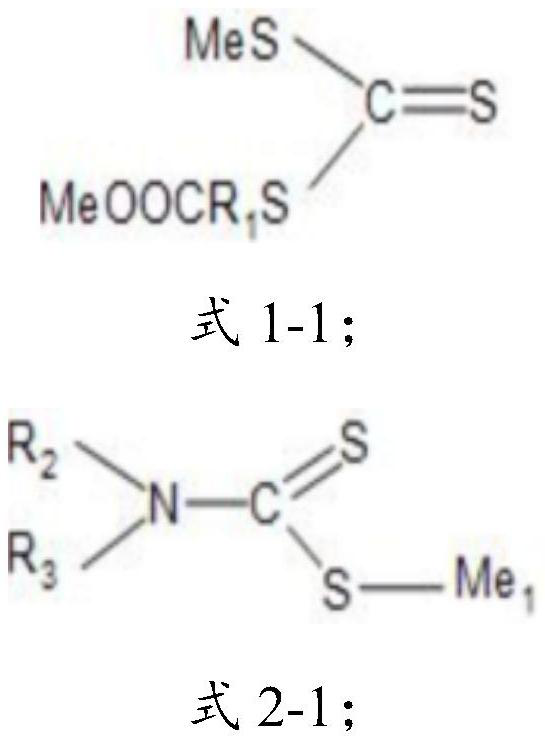

[0040] 1, the preparation of flotation agent, comprises the steps:

[0041] (1) With deionized water, 20 parts by weight of components shown in formula 1-2, 15 parts by weight of components shown in formula 2-2, 20 parts by weight of collector aid (kerosene), 10 parts by weight of foaming The agent (pine alcohol oil) is added to the volumetric flask of 200mL and constant volume;

[0042] (2) Place the volumetric flask of step (1) in a beaker with a constant temperature water bath at 50° C., and then stir the contents of the volumetric flask with a mechanical stirrer for 10 hours to obtain the flotation agent for future use.

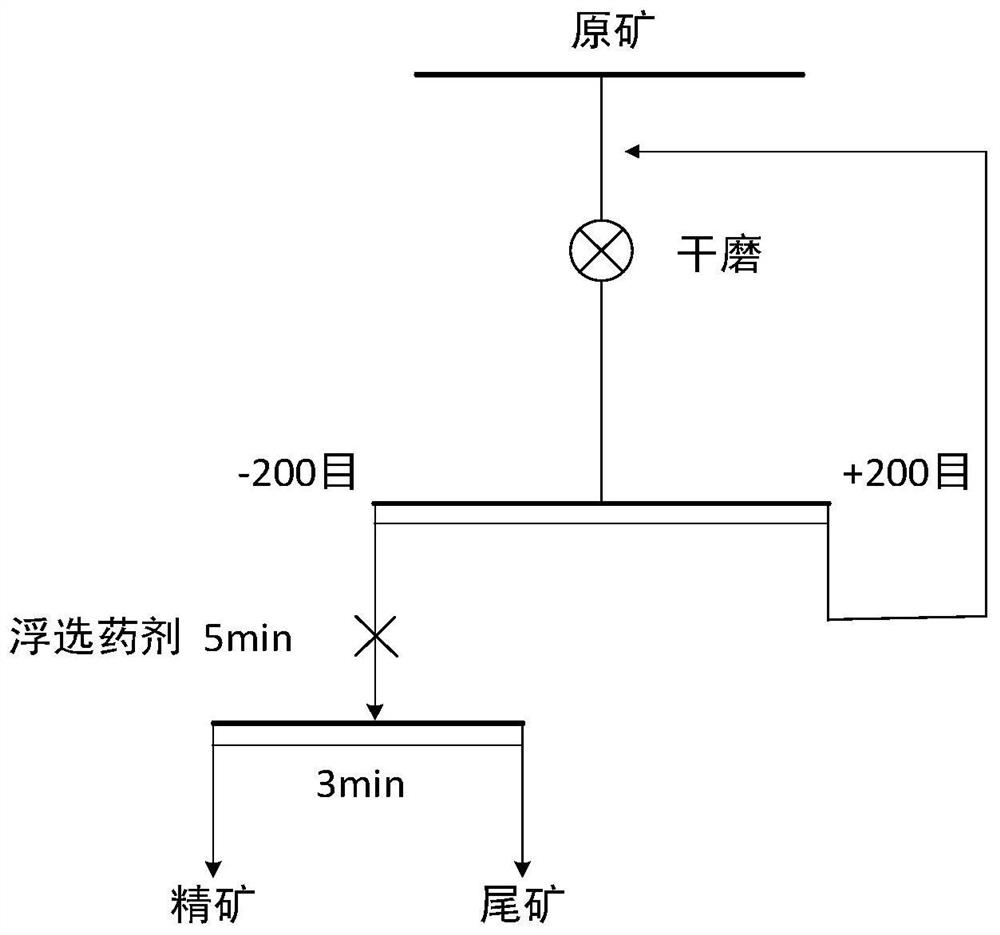

[0043] 2. Flotation test process: refer to figure 1 , put 2g of chalcopyrite pure minerals (from Yun County, Yunnan, the same below) into a 40mL flotation tank, add an appropriate amount of deionized water, and stir for 3 minutes to make the slurry evenly stirred, and add different proportions of the flotation flotation tanks prepared in this example. S...

no. 2 example

[0054] 1, the preparation of flotation agent, comprises the steps:

[0055] (1) With deionized water, 20 parts by weight of components shown in formula 1-2, 15 parts by weight of components shown in formula 2-2, 20 parts by weight of collector aid (kerosene), 10 parts by weight of foaming Add the agent (pine alcohol oil) to the 200mL volumetric flask to constant volume;

[0056] (2) Place the volumetric flask of step (1) in a beaker with a constant temperature water bath at 50° C., and then stir the contents of the volumetric flask with a mechanical stirrer for 10 hours to obtain the flotation agent for future use.

[0057] 2. Flotation test process: refer to figure 1 , put 2g molybdenite pure mineral (from Burma) into 40mL flotation tank, add appropriate amount of deionized water, stir for 3 minutes, make the slurry stir evenly, add the flotation agent prepared in this embodiment (addition amount is 500g / t), stir and inflate for 5 minutes, scrape and bubble for 3 minutes, ...

no. 3 example

[0067] 1, the preparation of flotation agent, comprises the steps:

[0068] (1) With deionized water, 20 parts by weight of components shown in formula 1-2, 15 parts by weight of components shown in formula 2-2, 20 parts by weight of collector aid (kerosene), 10 parts by weight of foaming The agent (pine alcohol oil) is added to the volumetric flask of 200mL and constant volume;

[0069] (2) Place the volumetric flask of step (1) in a beaker with a constant temperature water bath at 50° C., and then stir the contents of the volumetric flask with a mechanical stirrer for 10 hours to obtain the flotation agent for future use.

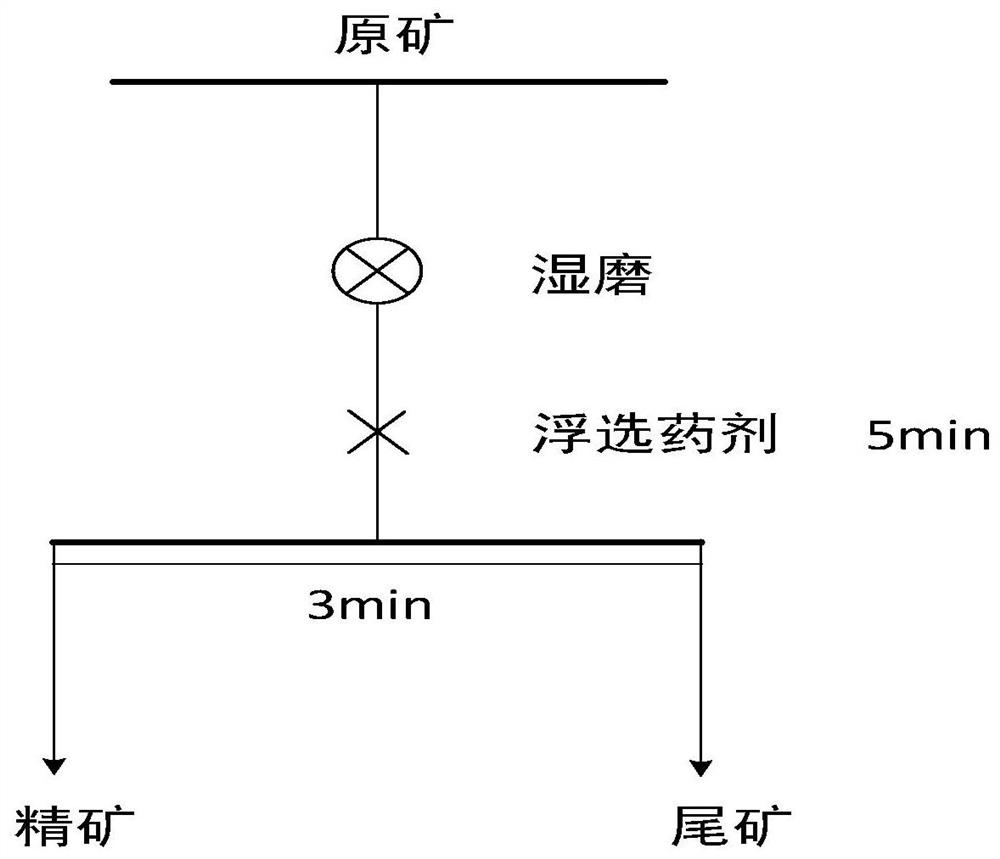

[0070] 2. Flotation test process: refer to figure 2 , put 500g of actual ore (copper grade 0.46%, molybdenum grade 3.62% the same below) into a 1.5L flotation tank, add an appropriate amount of deionized water, and stir for 3 minutes to make the slurry evenly stirred, and add different proportions of the prepared The flotation agent was used for flotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com