Diamond string beads, diamond wire saw and preparation method of diamond string beads

A technology of diamond beading and diamond, which is applied in metal sawing equipment, chemical instruments and methods, and tool manufacturing of sawing machine devices, etc. It can solve the problems of thickening of the overall thickness of the beading, limited bending degree, and reduction of the beading density, and achieve the beading density. Increase, length decrease, good bending ability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

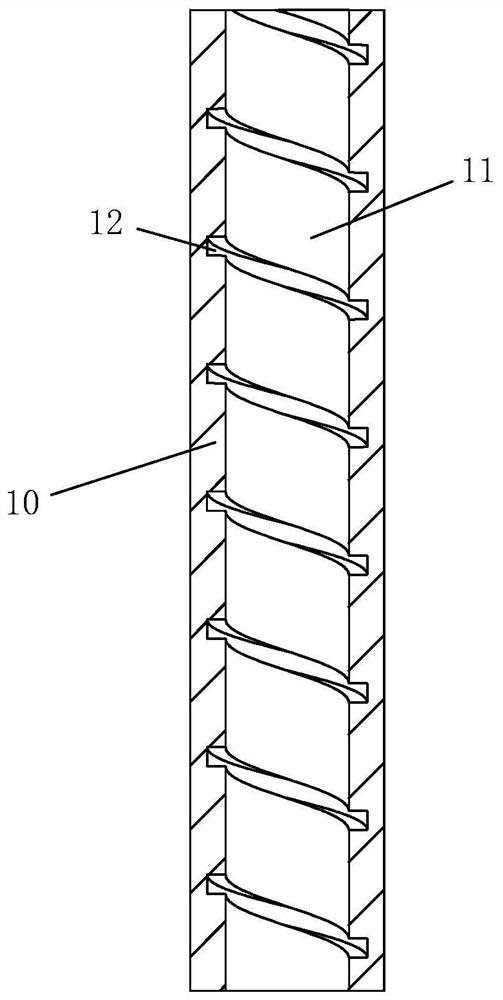

[0040] refer to figure 1 As shown, a diamond bead provided in this embodiment has and only has a diamond matrix 10, and the diamond matrix is a matrix with only a diamond working layer; that is, in the prior art, the diamond working layer is generally prepared on a steel pipe , steel pipe as a support seat. However, in this embodiment, the steel pipe is removed, and there is only the matrix of the diamond working layer, that is, there is and only one diamond matrix 10 . The diamond matrix 10 has a through hole 11 , and the inner wall of the diamond matrix 10 surrounding the through hole 11 is also recessed to form a thread groove 12 .

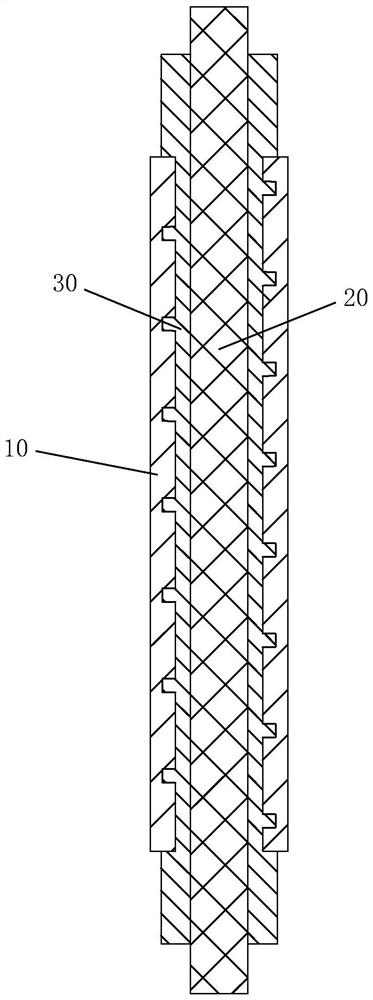

[0041] More specifically, the cross-section of the thread groove 12 is square, which is convenient for subsequent preparation of diamond wire saws, such as figure 2 As shown, the cladding layer 30 can penetrate into the thread groove 12 more easily, and the opening of the square thread groove 12 is large enough. The connection of the part...

Embodiment 2

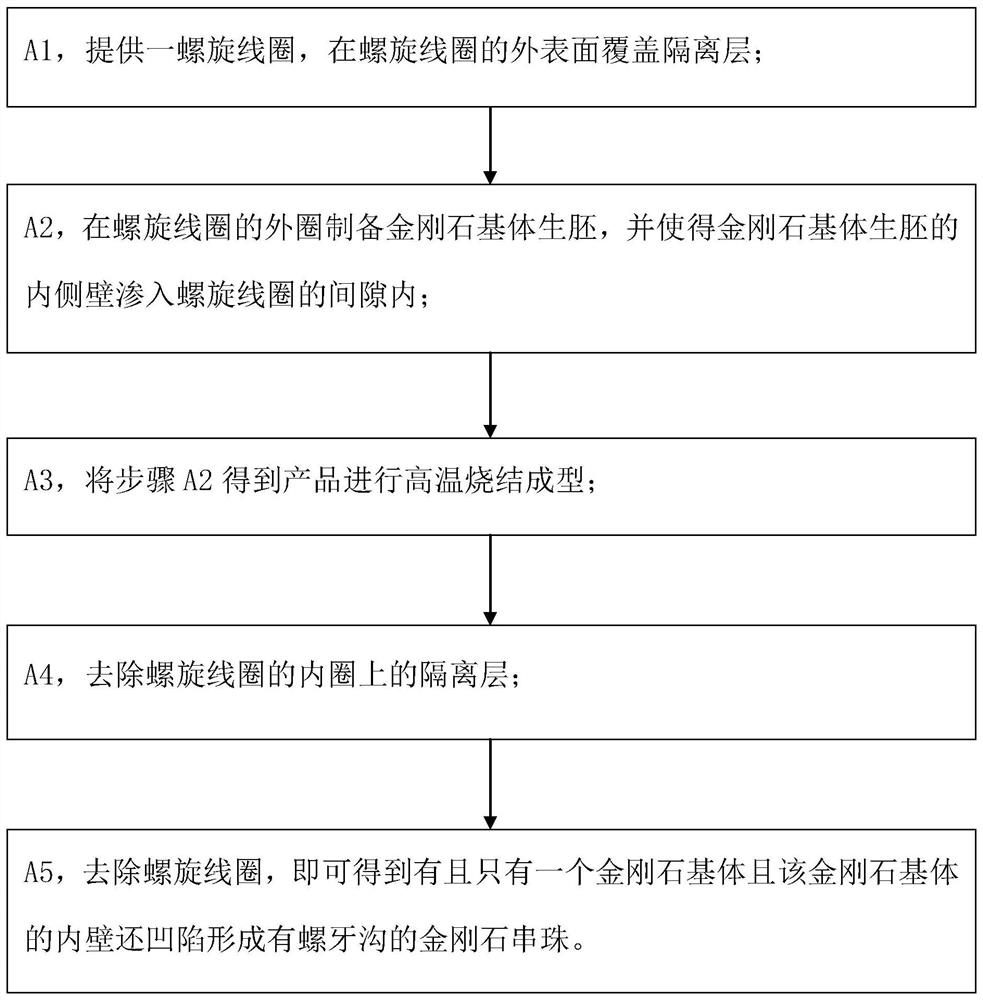

[0045] refer to image 3 As shown, the present embodiment provides a kind of preparation method of diamond beads, comprising the steps of:

[0046] A1, a helical coil 31 is provided, and the outer surface of the helical coil 31 is covered with an isolation layer 32, such as Figure 4 shown.

[0047] More specifically, in this embodiment, the cross-sectional shape of the isolation layer 32 is a square structure. During preparation, a mold can be prepared. The mold has a helical channel with a square section. The helical coil 31 is placed in the helical channel, and then injected into the isolation layer. Glue, the isolation layer 32 covering the outer surface of the helical coil 31 is obtained after the isolation glue is cured. Adopting the isolation layer 32 with a square cross section, the cross section of the thread groove 12 of the follow-up diamond matrix 10 is also square; to facilitate the follow-up preparation of the diamond wire saw, the cladding layer 30 can more ea...

Embodiment 3

[0059] refer to Figure 7 As shown, the present embodiment provides a kind of preparation method of diamond beads, comprising the steps of:

[0060] A1, providing a screw rod 40 with thread 41 on the outer peripheral surface, such as Figure 8 shown; and the outer peripheral surface of the screw 40 is covered with an isolation layer (not shown).

[0061] A2, prepare the diamond substrate 10 directly on the peripheral surface of the screw rod 40, such as Figure 9 , Figure 10 shown.

[0062] Specifically, in this step, since the screw 40 is a solid structure with sufficient support, the diamond matrix 10 is formed on the outer peripheral surface of the screw 40 by direct hot pressing and sintering when preparing the diamond matrix 10 . This preparation method is simpler and faster. Of course, in other embodiments, the green diamond substrate can also be cold-pressed onto the screw 40 by cold pressing, and then shaped by high-temperature sintering.

[0063] A3, removing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com