Textile printing and dyeing equipment

A textile printing and dyeing and equipment technology, applied in the field of textile printing and dyeing equipment, can solve problems such as inability to pre-press and flatten printed and dyed cloth, affect the health of operators, and inconsistent pattern color depth, etc., to protect health, speed up printing and dyeing, increase elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

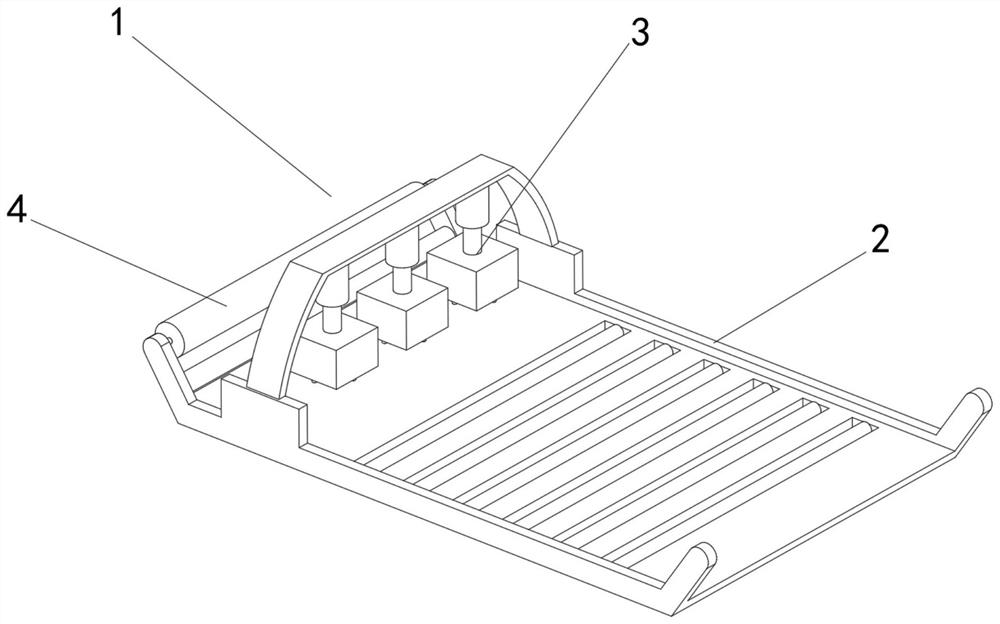

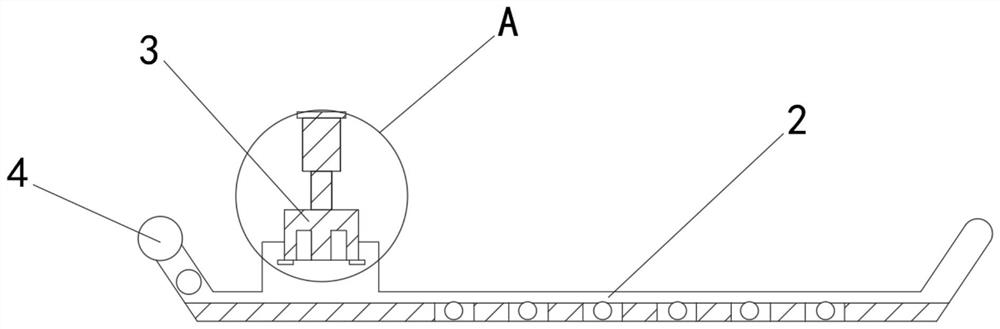

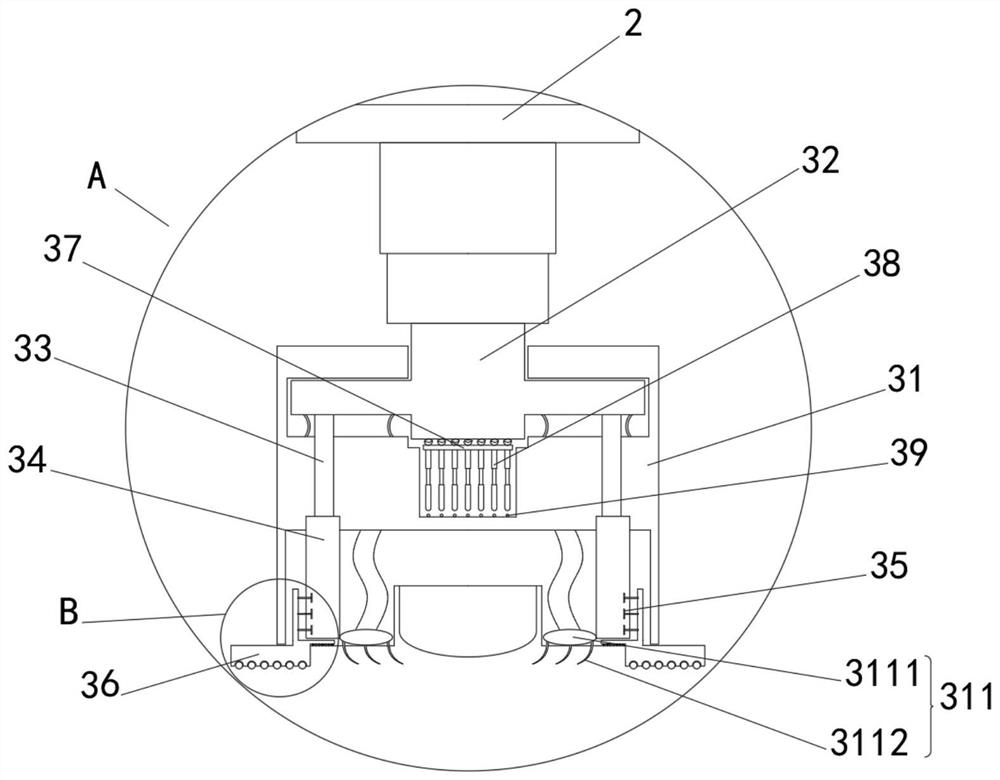

[0037] see Figure 1-3 , the present invention provides a technical solution: a textile printing and dyeing equipment, including a textile printing and dyeing equipment body 1 composed of a machine tool 2, a printing and dyeing mechanism 3 and a cloth guide roller 4, the outer side of the cloth guide roller 4 is connected to the inside of the machine tool 2 through a bearing Rotationally connected, the top of the printing and dyeing mechanism 3 is fixedly connected to the inside of the machine tool 2 through a hydraulic telescopic rod. The printing and dyeing mechanism 3 includes a printing and dyeing block 31. The outer side is slidingly connected to the outer side of the printing and dyeing block 31, the bottom of the receiving rod 32 is fixedly connected to the extrusion rod 33, the outer side of the extrusion rod 33 is slidingly connected to the inside of the printing and dyeing block 31, and the bottom of the extrusion rod 33 is slidingly connected to the oil pressure tube...

Embodiment 2

[0044] see Figure 1-4 , on the basis of Embodiment 1, the present invention provides a technical solution: the leveling mechanism 36 includes a translation block 361, the right side of the translation block 361 is fixedly connected to the left side of the piston rod 35, and the left side of the translation block 361 is passed through a spring set It is fixedly connected with the outside of the printing and dyeing block 31 , and the bottom of the translation block 361 is slidingly connected with the outside of the printing and dyeing block 31 through a shaft.

[0045] The inside of the translation block 361 is fixedly connected with the pressure rod 362, and the bottom end of the pressure rod 362 is fixedly connected with the pressure block 363, and the inner wall of the pressure block 363 is slidingly connected with a friction ball 364, and the outer side of the friction ball 364 is connected with the side of the translation block 361. Internal sliding connections.

[0046] ...

Embodiment 3

[0048] see Figure 1-5 , On the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the friction ball 364 includes an outline frame 3641, the inner wall of the outline frame 3641 is fixedly connected with a rebound capsule 3642, and the interior of the rebound capsule 3642 is provided with The elastic piece, the bottom of the resilient bag 3642 is fixedly connected with the inner frame 3643 through the elastic rod.

[0049] The inside of the rebounding bag 3642 is connected with the outside through a one-way valve 3644 , and the outside of the outer frame 3641 is connected with an air diffuser block 3645 .

[0050] When in use, when the friction ball 364 slides on the surface of the printing and dyeing cloth, it is squeezed by the printing cloth, the outer frame 3641 is slightly deformed, and the elastic bag 3642 is squeezed, and the air diffuser 3645 diffuses air. Compared with the traditional When the ball 364 slides on the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com