A kind of storage device for methyl methacrylate storage and using method thereof

A methyl methacrylate, storage device technology, applied in the directions of packaging, loading/unloading, transportation, and packaging, can solve the problems of storage container impact, reduced tank sealing performance, easy rotation and shaking of the tank, etc., to prevent Easy to turn and shake, the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and embodiments.

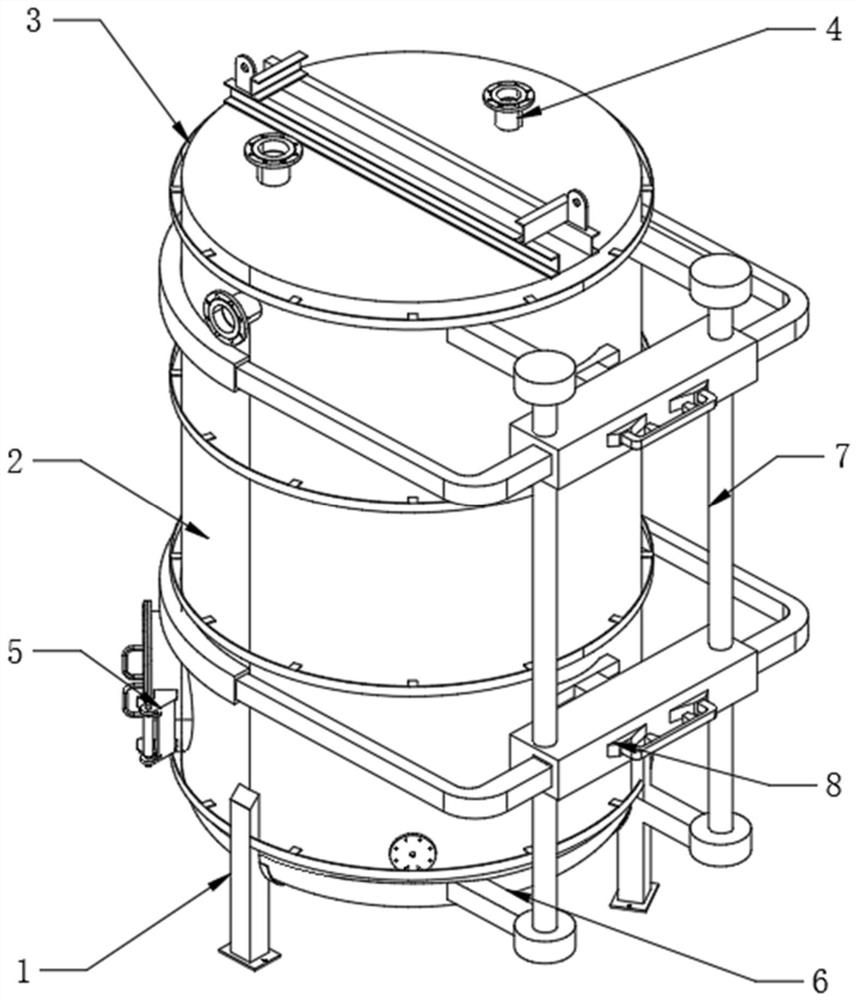

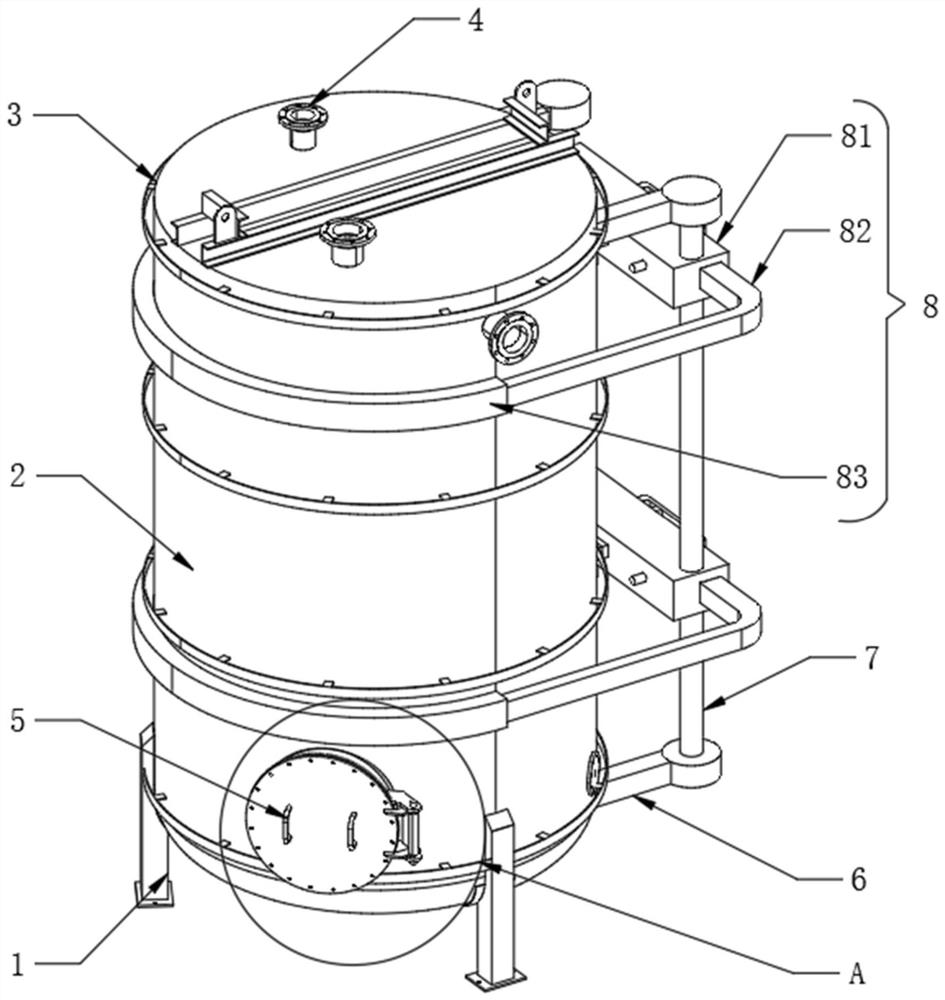

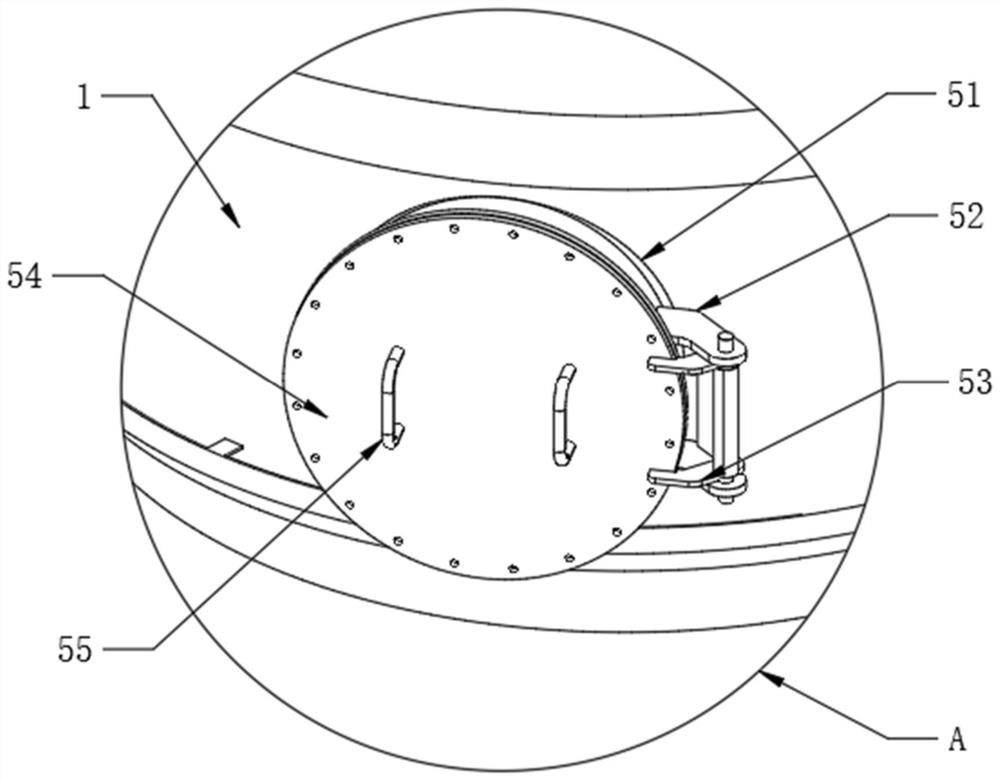

[0029] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ,in, figure 1 A schematic diagram of the overall first structure provided by the present invention; figure 2 A schematic diagram of the overall second structure provided by the present invention; image 3 for figure 2 The enlarged schematic diagram of the structure at A; Figure 4 The external schematic diagram of the structure of the pressing assembly provided by the present invention; Figure 5 It is a schematic diagram of the internal transmission structure of the pressing assembly provided by the present invention. The storage device for methyl methacrylate storage includes: a support frame 1 , a material storage tank 2 , a top cover 3 , a material guide pipe 4 , an opening and closing mechanism 5 , a fixed bracket 6 and a sliding column 7 .

[0030] In the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com