High-white-brightness strip-shaped aluminum pigment for ABS and preparation method thereof

A technology of aluminum pigment and brightness, which is applied in the field of strip aluminum pigment and its preparation, can solve the problems of poor white brightness and metal effect, and achieve the effects of improving compatibility, increasing added value, and increasing white brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

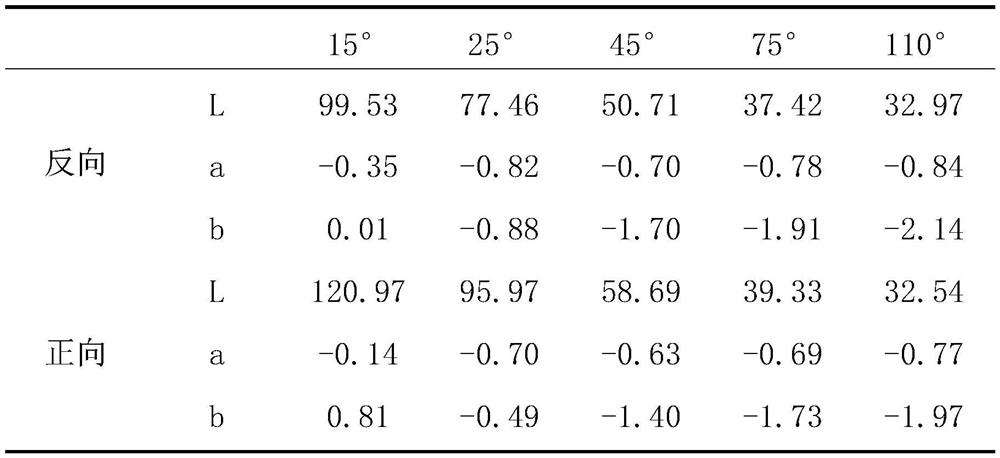

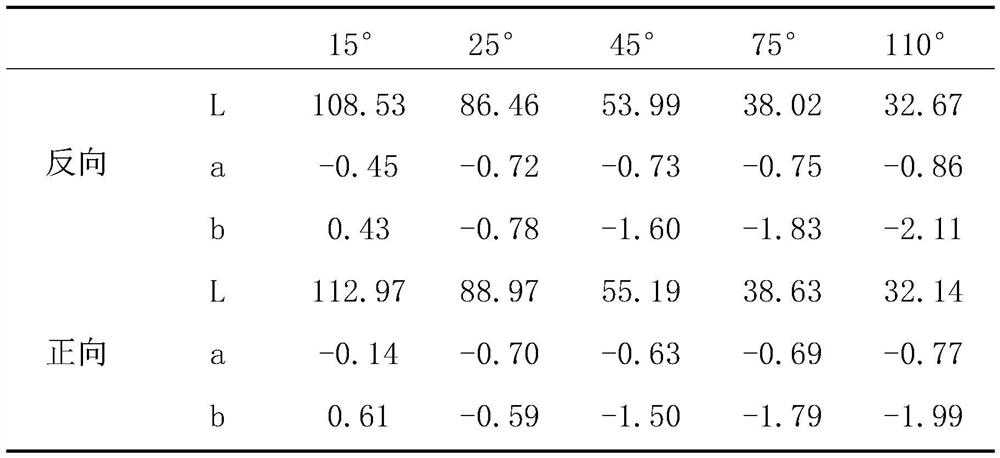

Embodiment 1

[0025] A kind of preparation method for the strip aluminum pigment of ABS high white brightness, its step comprises:

[0026] Step 1: Select an aluminum pigment with an aluminum content of 60%, a flake aluminum particle thickness of 0.2 μm, and a flake aluminum particle diameter D50 of 10um, put 1 part of aluminum pigment into the reaction kettle, add 4 parts of D60 solvent, and then add 0.1 part of methyl methacrylate monomer, stirred at a speed of 20rpm, heated the reactor to a constant temperature of 70°C, and dripped an azo initiator at a rate of 0.08ml per minute. The total amount of the initiator added was the weight of the monomer 5%, continue to stir for 4 hours, turn off the heating and age for 2 hours after the end of the stirring, after the end of the aging, discharge the material and press filter to remove the solvent, and obtain 65% solid-containing polymer-coated flake-shaped aluminum particles;

[0027] Step 2: Combine the polymer-coated flake aluminum particles...

Embodiment 2

[0029] A kind of preparation method for the strip aluminum pigment of ABS high white brightness, its step comprises:

[0030] Step 1: Select an aluminum pigment with an aluminum content of 65%, a flake aluminum particle thickness of 0.3 μm, and a flake aluminum particle diameter D50 of 12um, put 1 part of aluminum pigment into the reaction kettle, add 5 parts of D70 solvent, and then add 0.15 parts of butyl methacrylate monomer, stirred at a speed of 22rpm, and the reactor was heated to a constant temperature of 75°C, and an azo initiator was dropped in at a rate of 0.1ml per minute. The total amount of the initiator added was the weight of the monomer 8%, continue to stir for 3.5h, turn off the heating after the stirring is over, and age for 2.5h, after the aging is finished, discharge the material and press filter to remove the solvent, so as to obtain 70% solid polymer-coated flake-shaped aluminum particles;

[0031] Step 2: Combine the polymer-coated flake-shaped aluminum ...

Embodiment 3

[0033] A kind of preparation method for the strip aluminum pigment of ABS high white brightness, its step comprises:

[0034] Step 1: Select an aluminum pigment with an aluminum content of 70%, a flake aluminum particle thickness of 0.5 μm, and a flake aluminum particle diameter D50 of 15um, put 1 part of aluminum pigment into the reaction kettle, add 6 parts of D60 solvent, and then add 0.2 parts of butyl methacrylate monomer, stirred at a speed of 25rpm, and the reactor was heated to a constant temperature of 80°C, and an azo initiator was dropped in at a rate of 0.12ml per minute. The total amount of the initiator added was the weight of the monomer 10%, continue to stir for 3 hours, turn off the heating and age for 3 hours after the end of the stirring, after the end of the aging, discharge the material and press filter to remove the solvent, and obtain a polymer-coated aluminum pigment with a solid content of 75%;

[0035] Step 2: Combine the polymer-coated aluminum pigme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com