Non-migration and non-transferable high-temperature smooth master batch and preparation process thereof

A non-migration, high-temperature technology, applied in the field of functional polymer materials, can solve problems such as easy precipitation and transfer to the corona surface, difficulty in meeting the smoothness requirements, fast corona decay, etc., without affecting the appearance quality and improving Smooth opening and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this implementation, the above-mentioned non-migratory and non-transferable high-temperature slip masterbatch includes components by weight:

[0045] Copolypropylene 81.8

[0046] Polysiloxane 15, where n is 16 and molecular weight is 80,000

[0047] Silica 3, wherein the silica has pores, and its porosity is 2.0ml / g

[0048] Compound antioxidant 0.2;

[0049] Friction coefficient 0.18

[0050] High temperature friction coefficient 0.23

[0051] Initial / Stable Corona 48 / 38

[0052] Film haze 1.2.

Embodiment 2

[0054] In this implementation, the above-mentioned non-migratory and non-transferable high-temperature slip masterbatch includes components by weight:

[0055] Copolypropylene 74.8

[0056] Polysiloxane 20, where n is 16 and molecular weight is 80,000

[0057] Silica 5, wherein the silica has pores and has a porosity of 2.0ml / g

[0058] Compound antioxidant 0.2;

[0059] Friction coefficient 0.18

[0060] High temperature friction coefficient 0.23

[0061] Initial / Stable Corona 48 / 38

[0062] Film haze 1.2.

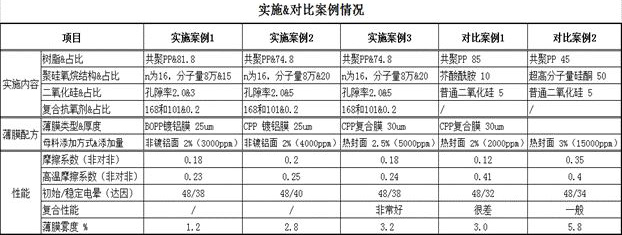

[0063] The specific contrast between the embodiment and the prior art is as follows:

[0064]

[0065] A preparation process for preparing the non-migrating and non-transferring high-temperature slippery masterbatch, comprising the steps of:

[0066] (1) Pretreatment of polysiloxane with porous silica to prepare a powdery mixture that can be continuously cut;

[0067] (2) Pour silicon dioxide into a mixing bucket with a stirring device, drop polysiloxane contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com