Non-contact induced quick-response solid powder color-changing material and preparation method thereof

A fast-response, solid powder technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, organic chemistry, etc., can solve the problems of loss of color-changing performance, limited application scenarios, ultraviolet light triggering, etc., and achieve reusable color change range span , Broaden the application scene, increase the effect of effective depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

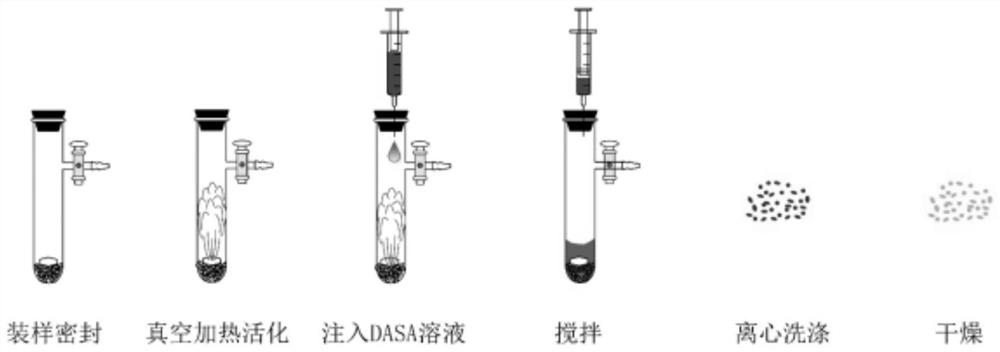

[0049] A preferred embodiment of the present invention provides a method for preparing a solid powder color-changing material that induces a rapid response without contact, and the specific steps are as follows:

[0050] (1) Preparation of molecular intermediates of DASAs: Mix cyclo(methylene)isopropyl malonate and furfural, stir at 35° C. for about 4 hours, and obtain a yellow intermediate product. Then the obtained yellow product was washed with water and suction filtered to remove the water therein. Then use saturated sodium bisulfite and saturated sodium chloride aqueous solution to extract the intermediate product to remove impurities therein, then use anhydrous magnesium sulfate or anhydrous sodium sulfate to further remove the moisture in the intermediate, and filter Remove anhydrous magnesium sulfate. Finally, the intermediate was finally purified by column chromatography, and the eluent was dichloromethane (DCM). Finally, the purified intermediate was obtained and t...

Embodiment 2

[0055] A preferred embodiment of the present invention provides a method for preparing a solid powder color-changing material that induces a rapid response without contact, and the specific steps are as follows:

[0056] (1) Preparation of molecular intermediates of DASAs: Mix cyclo(methylene)isopropyl malonate and furfural, stir at 35° C. for about 4 hours, and obtain a yellow intermediate product. Then the obtained yellow product was washed with water and suction filtered to remove the water therein. Then use saturated sodium bisulfite and saturated sodium chloride aqueous solution to extract the intermediate product to remove impurities therein, then use anhydrous magnesium sulfate or anhydrous sodium sulfate to further remove the moisture in the intermediate, and filter Remove anhydrous magnesium sulfate. Finally, the intermediate was finally purified by column chromatography, and the eluent was dichloromethane (DCM). Finally, the purified intermediate was obtained and t...

Embodiment 3

[0061] A preferred embodiment of the present invention provides a method for preparing a solid powder color-changing material that induces a rapid response without contact, and the specific steps are as follows:

[0062] (1) Preparation of molecular intermediates of DASAs: Mix cyclo(methylene)isopropyl malonate and furfural, stir at 35° C. for about 4 hours, and obtain a yellow intermediate product. Then the obtained yellow product was washed with water and suction filtered to remove the water therein. Then use saturated sodium bisulfite and saturated sodium chloride aqueous solution to extract the intermediate product to remove impurities therein, then use anhydrous magnesium sulfate or anhydrous sodium sulfate to further remove the moisture in the intermediate, and filter Remove anhydrous magnesium sulfate. Finally, the intermediate was finally purified by column chromatography, and the eluent was dichloromethane (DCM). Finally, the purified intermediate was obtained and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com