Large-diameter steel pipe anti-slide pile anti-corrosion protection layer and construction method thereof

A protective layer and anti-slide pile technology, which is applied to the anti-corrosion protection layer of large-diameter steel pipe anti-slide piles and its construction field, can solve the problems of poor corrosion resistance of anti-slide piles, avoid corrosion, improve pile support capacity, The effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

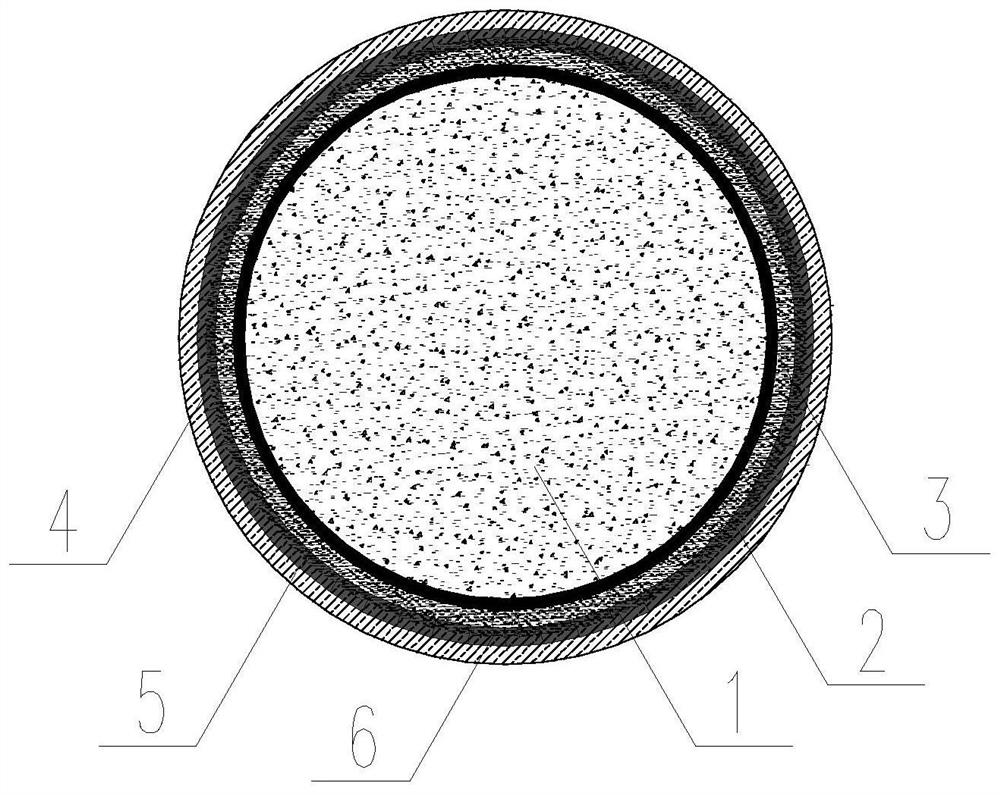

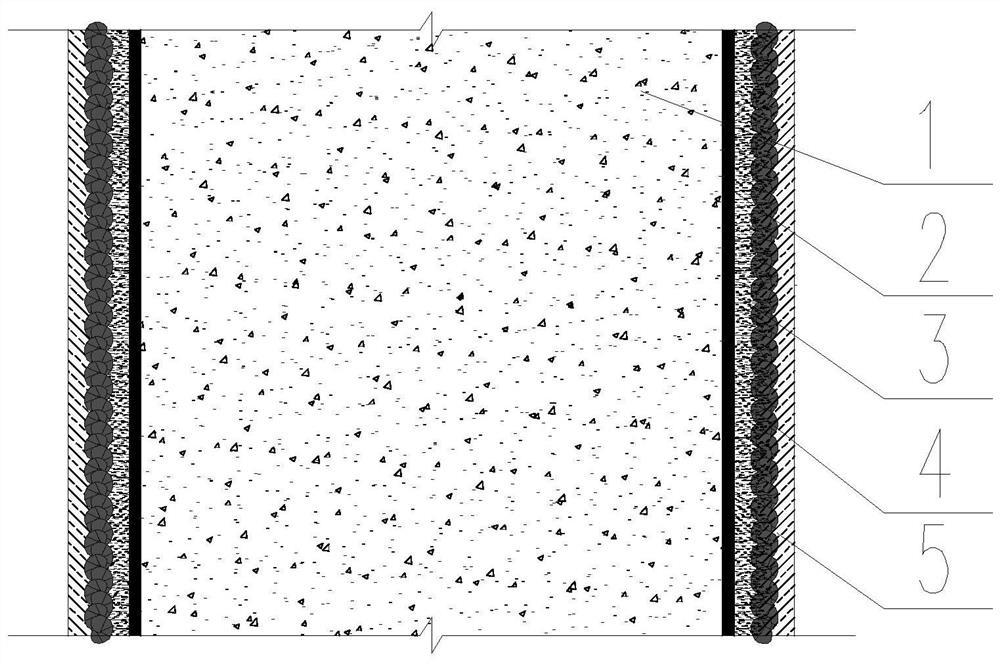

[0033] The invention provides an anti-corrosion protection layer of a large-diameter steel pipe anti-sliding pile and a construction method thereof, comprising a concrete core pile 1, and a steel pipe 2, a fiber concrete protection layer 3, a polymer corrugated pipe 4 and a concrete core pile 1 are sequentially arranged outside the concrete core pile 1 Grouting body 5.

[0034] The material strength grade of the concrete core pile 1 and the wall thickness and diameter of the steel pipe 2 are determined according to the specific conditions of the treatment project, and must meet the design bearing capacity requirements.

[0035] The fiber reinforced concrete protective layer 3 is made of fine stone fiber reinforced concrete, in which steel fibers are added to reduce the generation of cracks and improve the working performance of the protective layer.

[0036] The diameter of the polymer bellows 4 is 4-10cm larger than the diameter of the steel pipe pile, and the difference betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com