Method for representing transmission behavior in molten pool in double-roller cast rolling process

A casting and rolling, molten pool technology, applied in the direction of surface/boundary effects, material analysis using wave/particle radiation, instruments, etc., can solve problems such as uneven heat flow in the molten pool of the twin-roll casting and rolling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

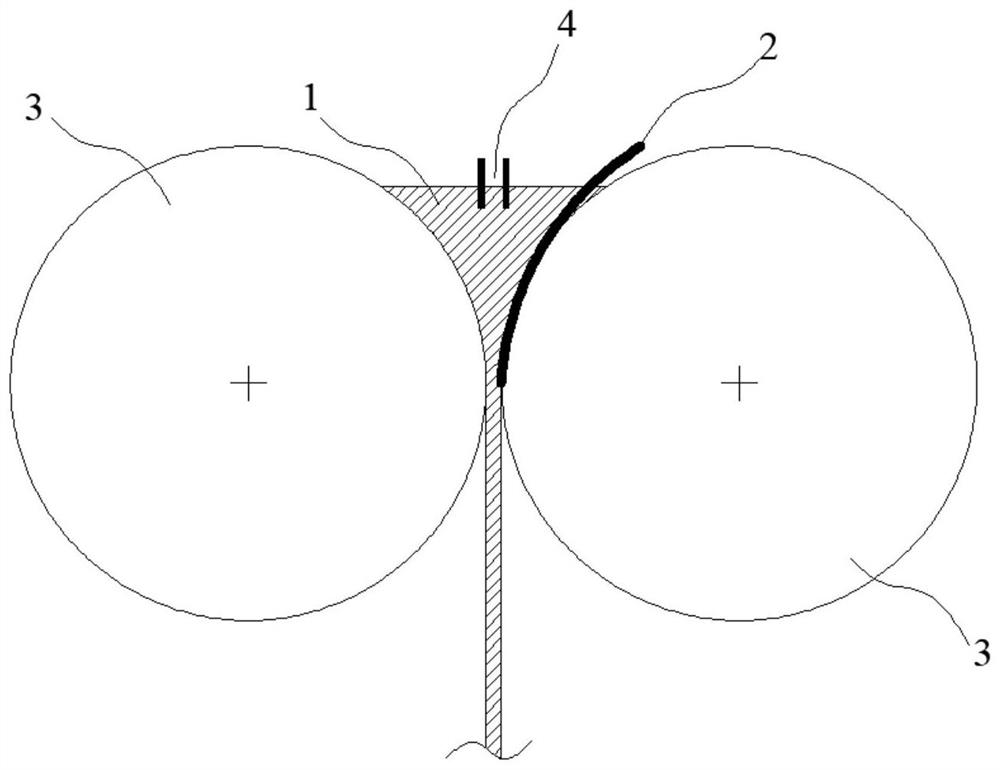

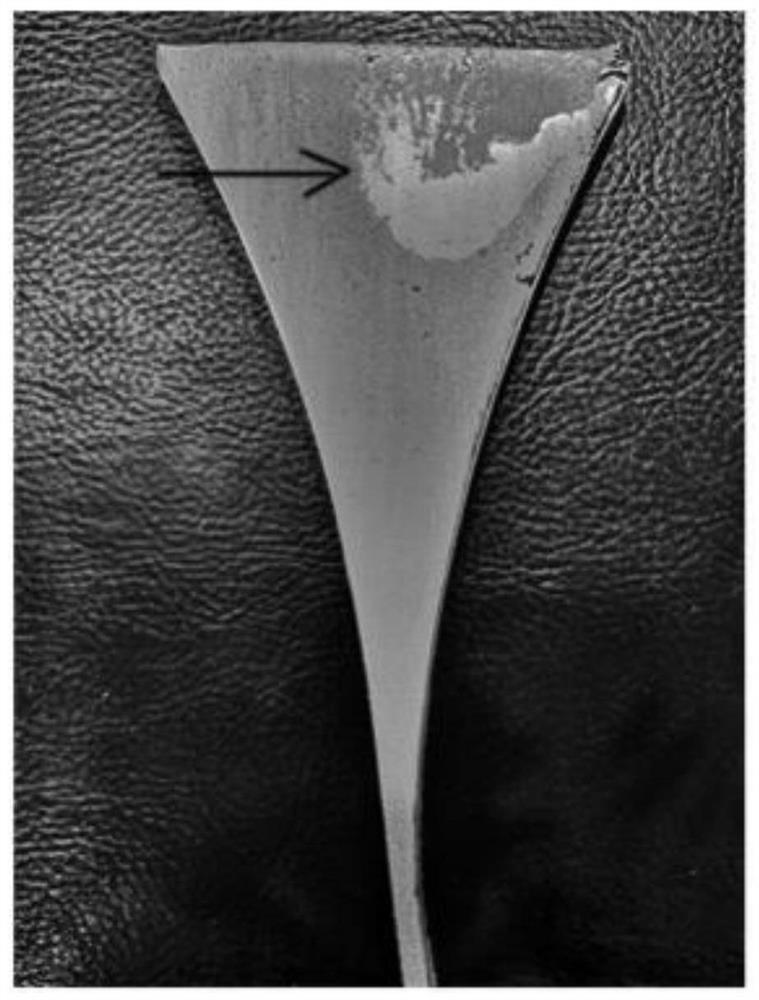

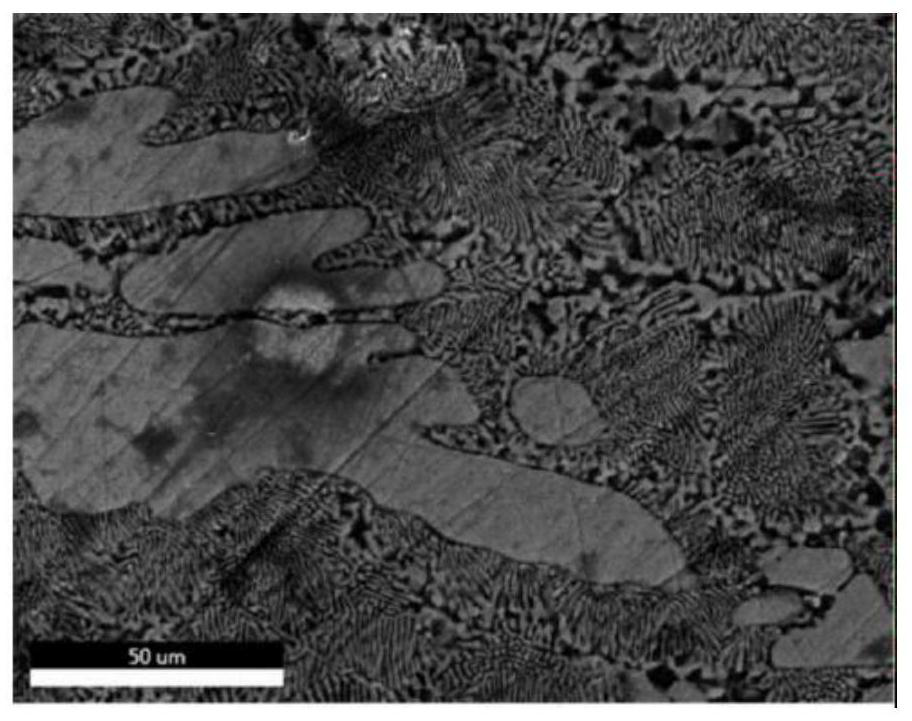

[0025] In this example, pure aluminum is used as the metal 1 to be cast and rolled, and a two-roll casting test is carried out. The casting equipment used is a conventional two-roll casting machine, including a control system, a distribution system, a crystallization roll 3 and a side sealing plate. , the crystallization roller 3 of the present embodiment is made of steel, and the diameter of the crystallization roller 3 is 160mm, and the length of the roller body is 200mm. above the molten pool, such as figure 1 shown. In addition, in this embodiment, strip-shaped solid metallic pure copper is used as the tracer 2 . The cross-section of the solid metallic copper is rectangular and the thickness is 0.5 mm. In other embodiments, the material of the tracer 2 is not limited to solid copper, and the cross-section of the tracer 2 is not limited to a square shape, for example, the cross-section can be selected to be circular, tooth-shaped, triangular, etc.

[0026] Melt the alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com