Method and device for generating high-power vortex laser

A high-power, vortex technology, applied in the direction of optics, optical components, instruments, etc., can solve the problems of broadband laser dispersion, can not withstand high-power laser, low diffraction efficiency, etc., to solve the problem of dispersion, improve energy utilization, suppress The effect of side lobes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

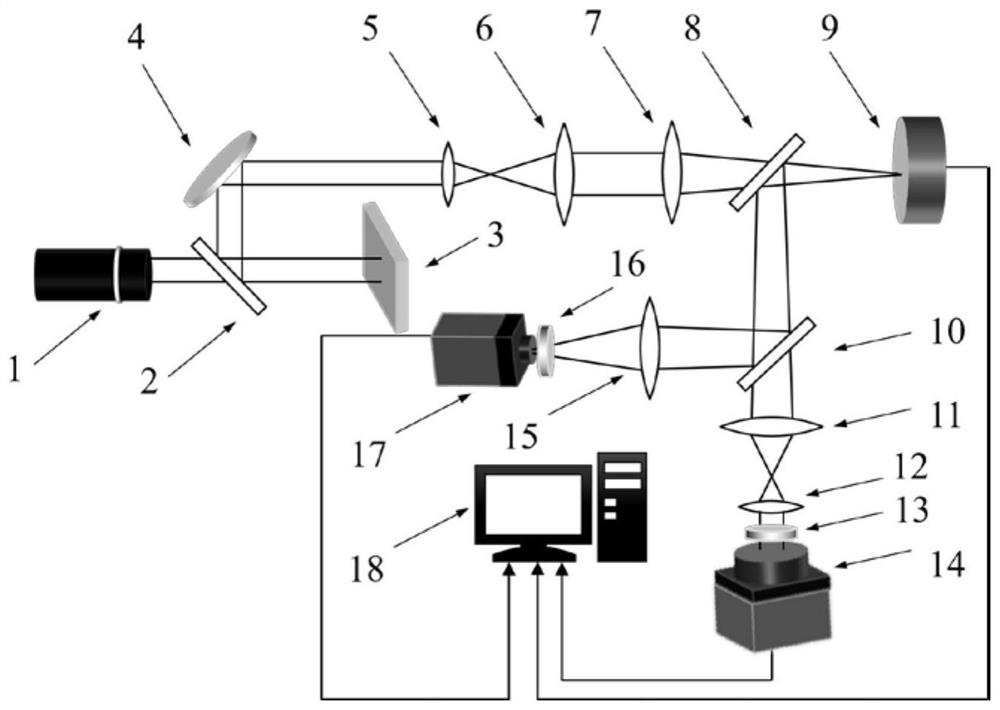

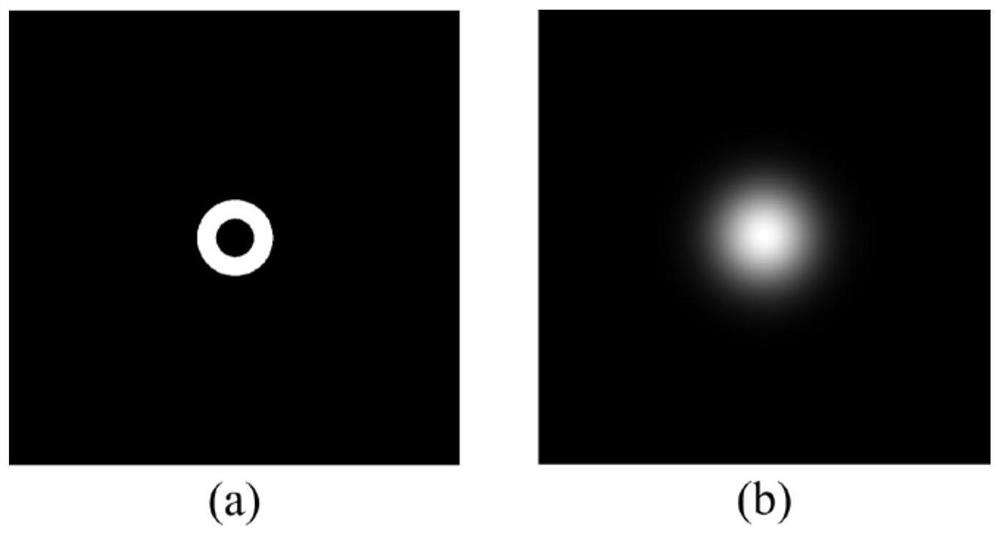

[0046] Embodiment 1: This embodiment demonstrates the result of using a continuous surface deformable mirror to load a ring helicoid with a topological charge equal to 2 to generate vortex laser light for the annular light field emitted by an unstable cavity laser.

[0047] For the annular light field emitted by the unstable cavity laser, figure 1 The device in the figure removes the first focusing lens 7, and the optical shaping plate 3 is not loaded with a surface shape, which is a mirror. First, the voltage of the continuous surface deforming mirror 9 is set to zero, and the annular light field emitted by the laser 1 passes through the first lens 5 and the second lens 6, expands the beam to the beam width required by the continuous surface deforming mirror 9, and then passes through the second dichroic prism 8 Arrive at the continuous surface deforming mirror 9, reflect through the continuous surface deforming mirror 9 and the second dichroic prism 8, reach the third dichro...

Embodiment 2

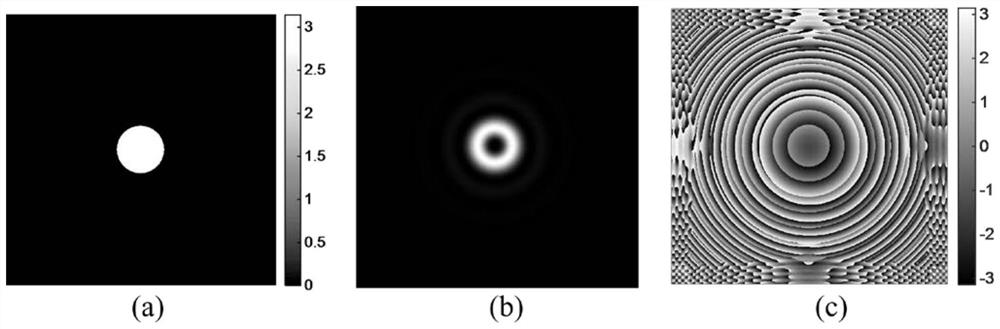

[0061] Embodiment 2: This embodiment shows that after the Gaussian light field emitted by the laser 1 is pre-shaped, a continuous surface deformable mirror 9 is used to fit a ring-shaped helicoid with a topological charge of 1 to generate a high-power vortex laser.

[0062] For a solid light field, figure 1 The device shown remains unchanged. First, the Gaussian light field emitted by the laser 1 passes through the first beam splitter 2, and then irradiates on the optical shaping plate 3, and the light field is sent to the first lens 5 and the second lens 6 to form an expansion plate through the optical shaping plate 3 and the reflector 4. The beam system, after beam expansion, is focused on the continuous surface deformable mirror 9 by the first focusing lens 7, and the annular light field is obtained on the plane where the continuous surface deformable mirror 9 is located. It is reflected by the continuous surface deforming mirror 9 to the second beam splitter 8, and then r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com