Aero-engine fault diagnosis method based on 5G edge calculation and deep learning

An aero-engine and edge computing technology, applied in neural learning methods, computer-aided design, computing, etc., can solve problems such as safety and efficiency hazards in aerial operations, harsh working environments, and reduced work performance, so as to improve storage and transmission speeds , reduce data transmission costs, and achieve ideal recognition results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

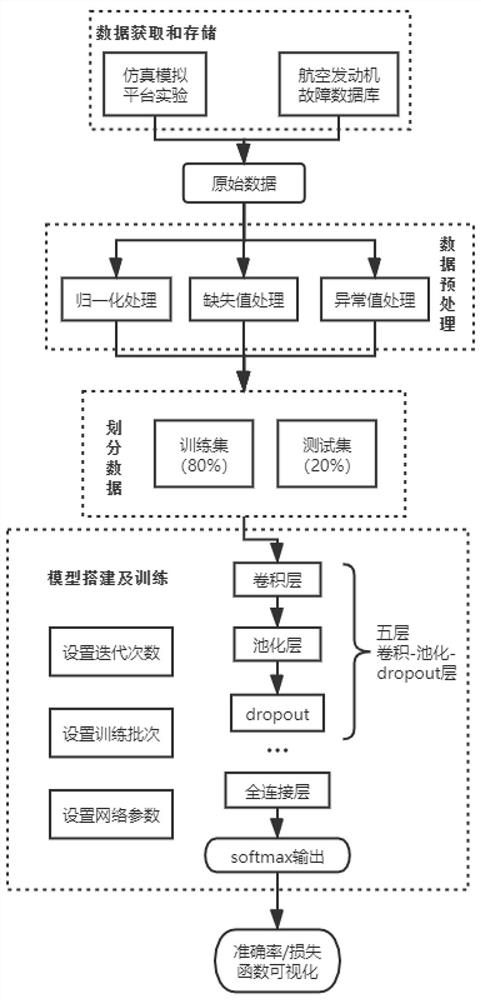

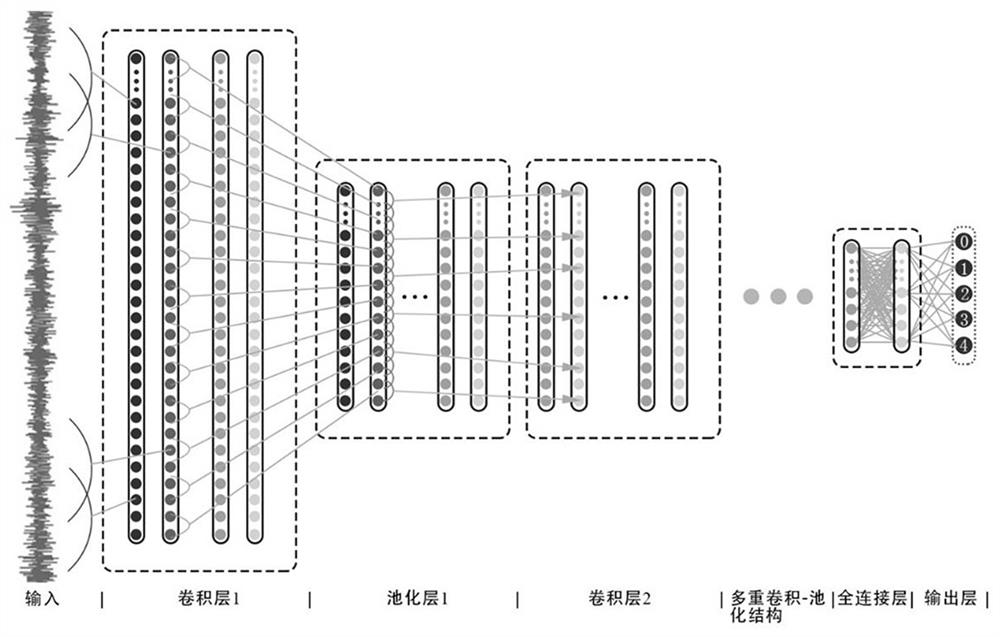

[0052] An aero-engine fault diagnosis method based on 5G edge computing and deep learning, the process is as follows figure 1 shown, including the following steps:

[0053] Step 1. Data collection, preprocessing and storage based on the new 5G cloud-edge-terminal network architecture;

[0054] Step 1.1. Data collection: Build an aero-engine gear fault simulation platform, adopt edge computing technology (5G core technology), and arrange base stations in the edge network close to the aero-engine gear fault simulation platform for data collection, and data is directly processed at the edge of the network. Processing, transmission and storage to avoid the delay and loss caused by the data returning to the core network 2; the acceleration sensor installed on the aero-engine gear fault simulation platform collects the vibration signals of different types of gears in different positions and directions, and converts the vibration signals into Voltage signal; the number of time slots...

Embodiment 2

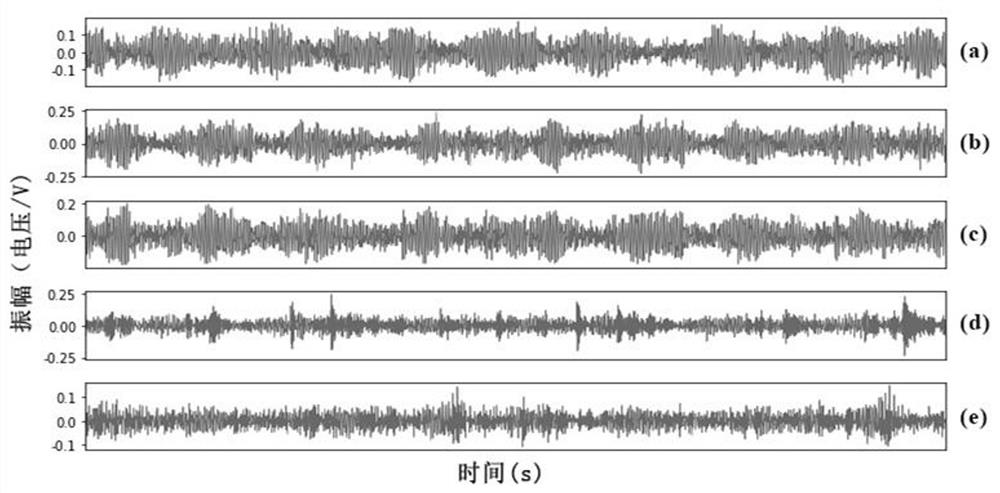

[0084] On the basis of Example 1, as figure 2 As shown, five different fault types (normal gear (a), broken tooth (b), missing tooth (c), tooth surface wear (d), tooth root crack) under the same sensor arrangement collected for the aero-engine gear fault simulation platform (e), the vibration signal data (the horizontal axis is the sampling time, the vertical axis is the conversion of the amplitude signal collected by the acceleration sensor into the voltage value), which can be added and deleted according to the specific situation), this data can also be obtained through the actual operation of the aero-engine. Collected real-time status data. The sampling frequency and sensor location arrangement set during data acquisition can be determined according to the actual situation. If necessary, in order to improve the accuracy of model training, other types of sensors such as acoustic sensors can be added. After obtaining the original data, data preprocessing is performed, miss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com