Preparation method and system of iron-chromium redox battery electrolyte

An electrolyte and electrolyte pipeline technology, applied in the field of energy storage, can solve problems such as increasing the cost of equipment or raw materials, and achieve the effects of reducing the amount of raw materials, accurate concentration, and improving battery performance and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

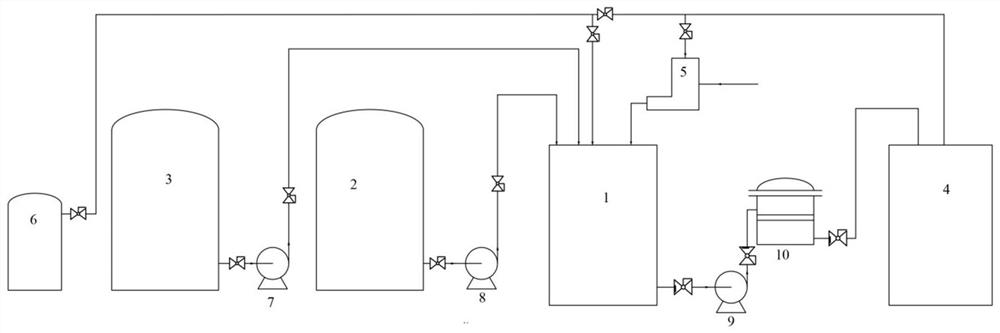

[0040] see figure 1 , the present embodiment proposes a system for preparing an electrolyte for an iron-chromium redox battery, comprising an electrolyte dissolution kettle 1, a pure water tank 3, a hydrochloric acid tank 2, a solid feeding device 5, an electrolyte filter 10 and an electrolyte storage tank 4,

[0041] The pure water tank 3, the hydrochloric acid tank 2, and the solid feeding device 5 are respectively connected to the top of the electrolyte dissolution kettle 1 through pipelines;

[0042] The lower part of the electrolyte solution kettle 1 is connected to the electrolyte filter 10 through the electrolyte pipeline, and the electrolyte filter 10 is connected to the electrolyte storage tank 4 .

[0043] In the present embodiment, the electrolytic solution dissolving kettle 1 adopts a tank body lined with tetrafluoroethylene, and an acid-resistant steel-lined tetrafluoroethylene stirring device is installed in the reaction vessel;

[0044] Both the pure water tan...

Embodiment 2

[0052] This embodiment proposes the preparation method of the electrolyte of iron-chromium redox battery, adopts the system of embodiment 1, comprises operation:

[0053] 1) Add water into the electrolyte dissolution kettle 1;

[0054] 2) open the nitrogen to make the nitrogen fill the dissolving kettle, and chromium chloride (CrCl 3 ·6H 2 (2) and hydrochloric acid are added in the electrolytic solution dissolving kettle 1 under the condition of cutting off the air, open and stir in the process of adding chromium chloride;

[0055] 3) After fully stirring, after the chromium chloride is completely dissolved, add ferrous chloride (FeCl 2 4H 2 O) join in the electrolytic solution dissolving kettle 1 under the condition of cutting off the air, stir until ferrous chloride dissolves completely.

[0056] 4) The electrolyte is filtered into the electrolyte storage tank, filled with nitrogen, and sealed for storage.

[0057] In this embodiment, the water used in step 1) is pure wat...

Embodiment 3

[0069] This embodiment proposes the preparation method of the electrolyte of iron-chromium redox battery, adopts the system of embodiment 1, comprises operation:

[0070] 1) Add water into the electrolyte dissolution kettle 1;

[0071] 2) open the nitrogen of the dissolving still, make nitrogen be full of dissolving still; Chromium chloride (CrCl 3 ·6H 2 (2) and hydrochloric acid are added in the electrolytic solution dissolving kettle 1 under the condition of cutting off the air, open and stir in the process of adding chromium chloride;

[0072] 3) After fully stirring, after the chromium chloride is completely dissolved, ferrous chloride is added into the electrolyte dissolution kettle 1 under the condition of cutting off the air, and stirred until the ferrous chloride is completely dissolved.

[0073] 4): Filter the electrolyte into the electrolyte storage tank, fill it with nitrogen, and keep it sealed.

[0074] In this embodiment, the water used in step 1) is pure wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com