Rotor structure of a double-layer sheathed permanent magnet motor

A permanent magnet motor, rotor structure technology, applied in the magnetic circuit shape/style/structure, motor, magnetic circuit rotating parts and other directions, can solve the problems of low utilization rate and low strength of permanent magnet materials, and avoid high temperature loss of magnetism , good stability, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

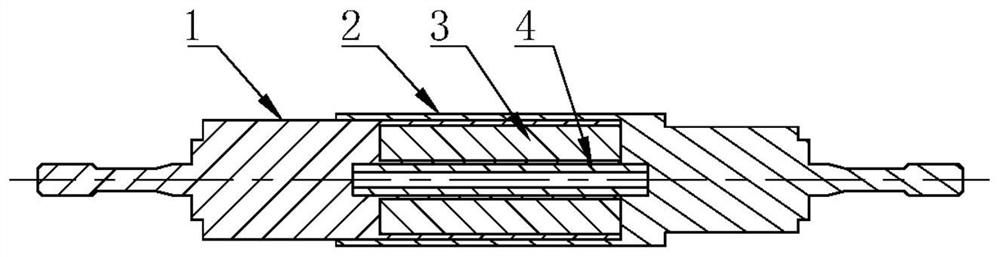

[0029] Embodiment 1: as figure 1 The rotor structure of a double-sheathed permanent magnet motor shown includes a first mandrel 1 , a second mandrel 2 , a permanent magnet unit 3 and a third mandrel 4 . The material of the first mandrel 1 and the second mandrel 2 is non-magnetic alloy steel and the outer surface is plated with tin bronze. The non-magnetic material can weaken the transmission path of magnetic flux leakage, reduce magnetic flux leakage, and improve motor performance; tin Bronze is used to reduce wind friction loss, thereby reducing heat generation and limiting rotor temperature rise. The material of the third mandrel 4 is a magnetic permeable alloy material, and the material of the permanent magnet unit 3 is a samarium cobalt permanent magnet material with a small temperature coefficient and a high working temperature.

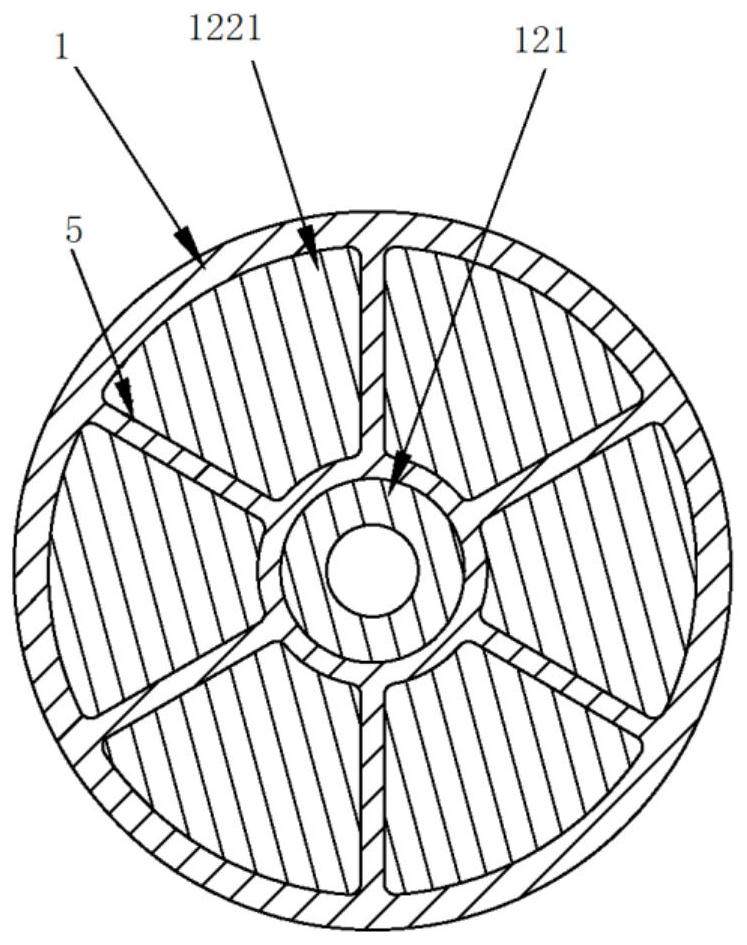

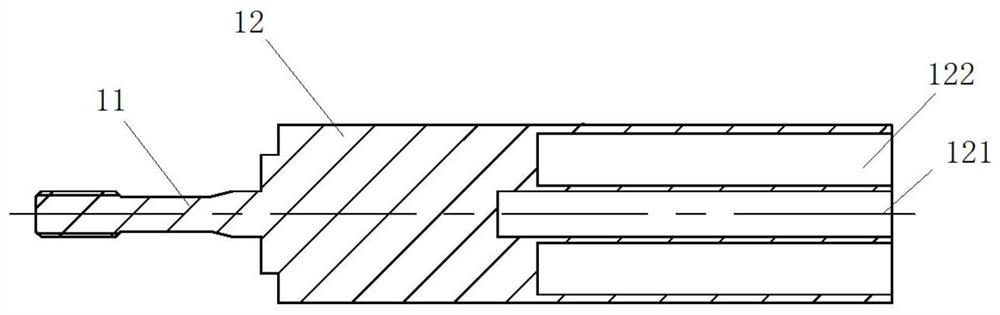

[0030] like figure 2 , 3 As shown, the first mandrel 1 is a stepped shaft structure, including a first end 11 and an inner sheath 12 integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com