A kind of manufacturing method of antibacterial and skin-friendly baby diapers

A technology for baby diapers and a production method, which is applied in the field of baby products production, can solve the problems of affecting spinning processing, non-woven fabrics are prone to burrs, heat loss, etc., and achieve the effect of preventing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

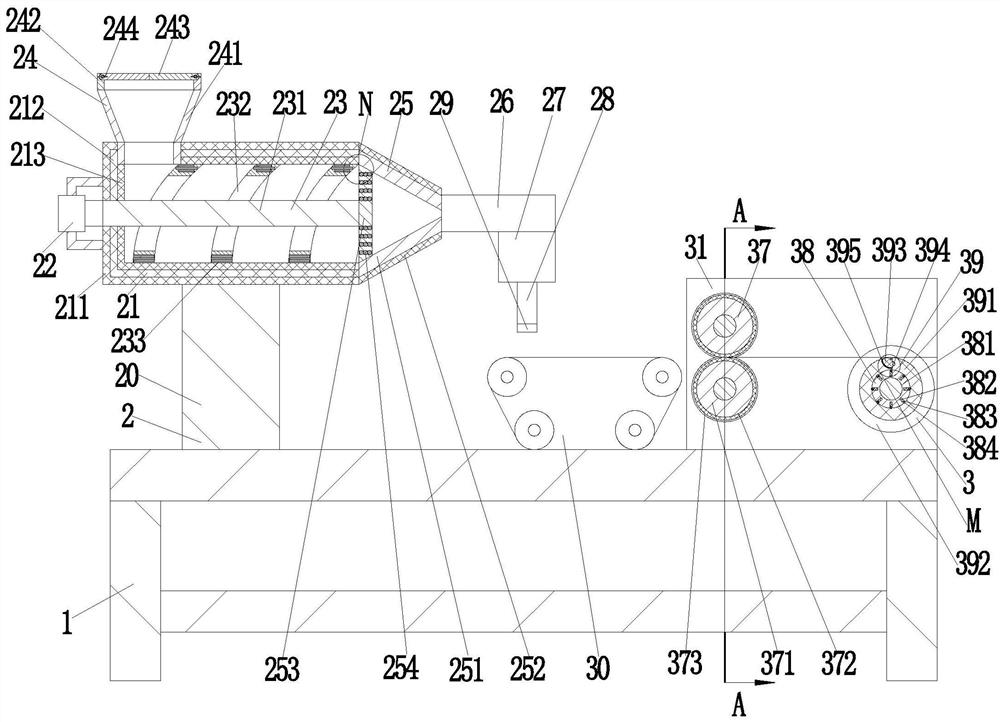

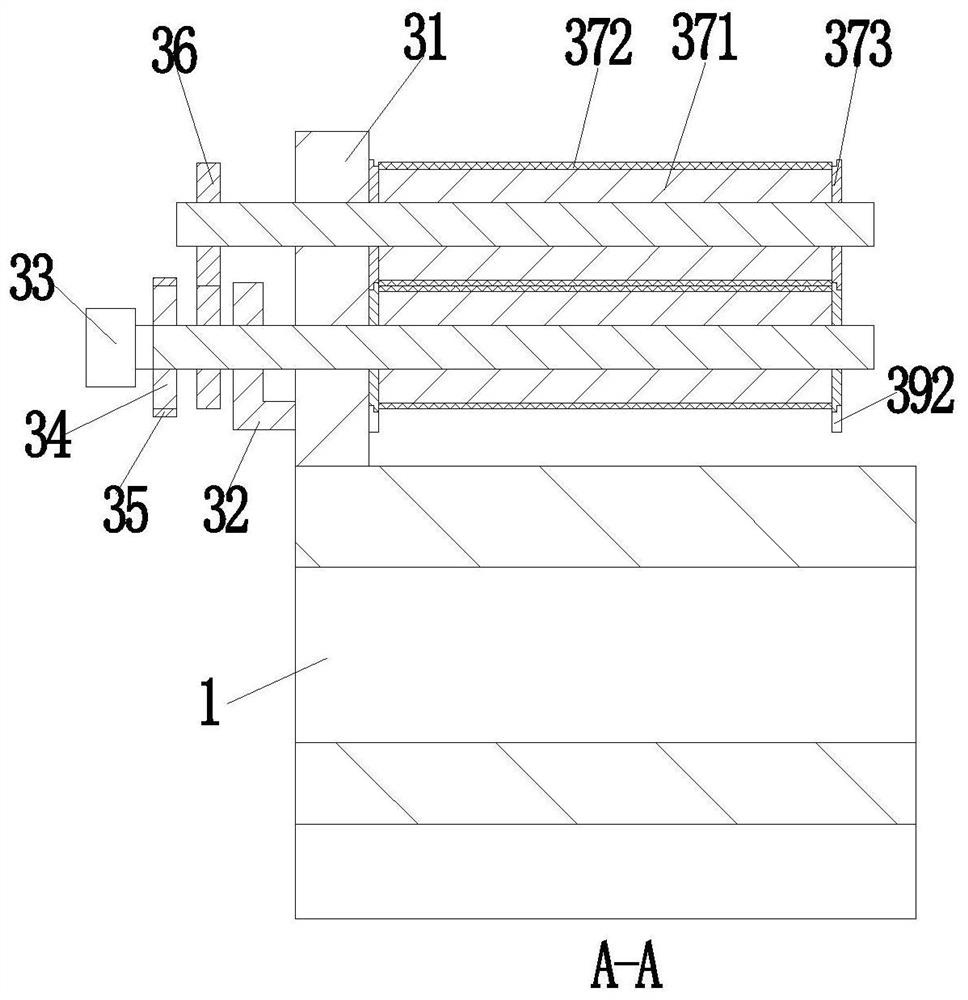

[0036] In order to make the technical means, creation features, achievement goals and effects realized by the present invention easy to understand and understand, the following combination Figure 1 to Figure 6 , the present invention will be further elaborated.

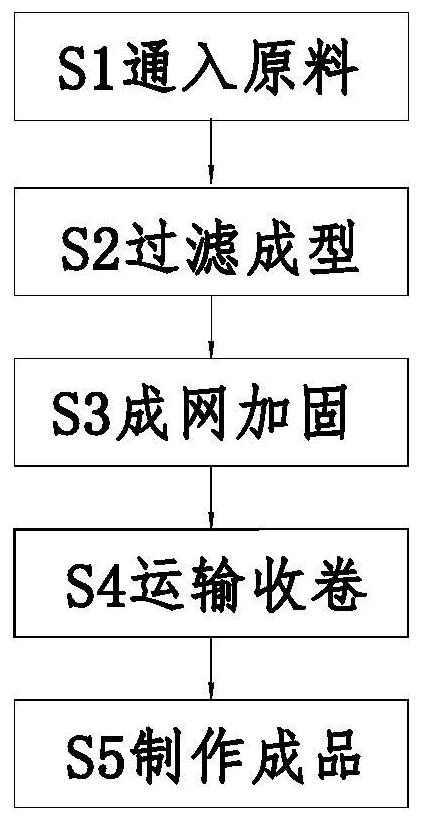

[0037] An antibacterial and skin-friendly baby diaper production method, which uses an antibacterial and skin-friendly baby diaper production equipment. The antibacterial and skin-friendly baby diaper production equipment includes a workbench 1, a molding device 2 and a transport device 3. The above-mentioned antibacterial and skin-friendly baby diaper is used. The specific method of making antibacterial and skin-friendly baby diapers by the diaper making equipment is as follows:

[0038] S1, feed the raw material: pass the raw material and the hydrophilic agent into the mixing drum 21 through the feeding funnel 24 for heating and stirring, until it is in a molten liquid state;

[0039] S2. Filtration and shaping: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com