A kind of aluminothermic reduction ceria octahedral material and its preparation method and application

A technology of ceria and octahedron, which is applied in the field of aluminothermic reduction of ceria octahedron material and its preparation, can solve the problems of poor inherent activity and limitation of large-scale application, and achieve reduced adsorption energy, excellent electrochemical performance, The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

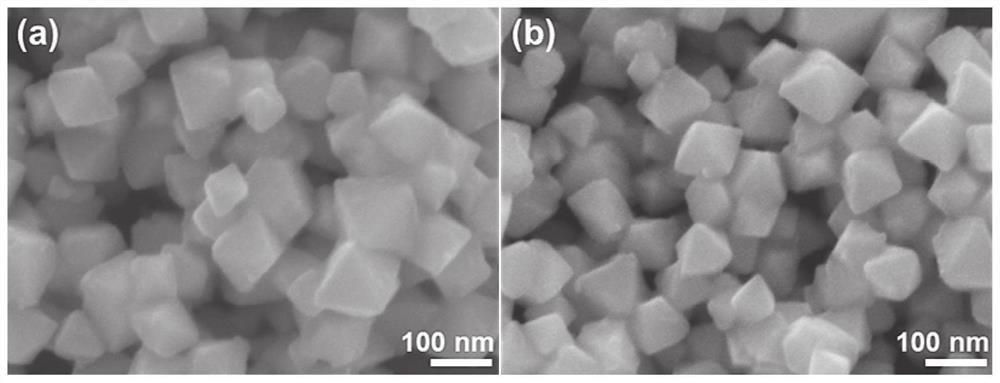

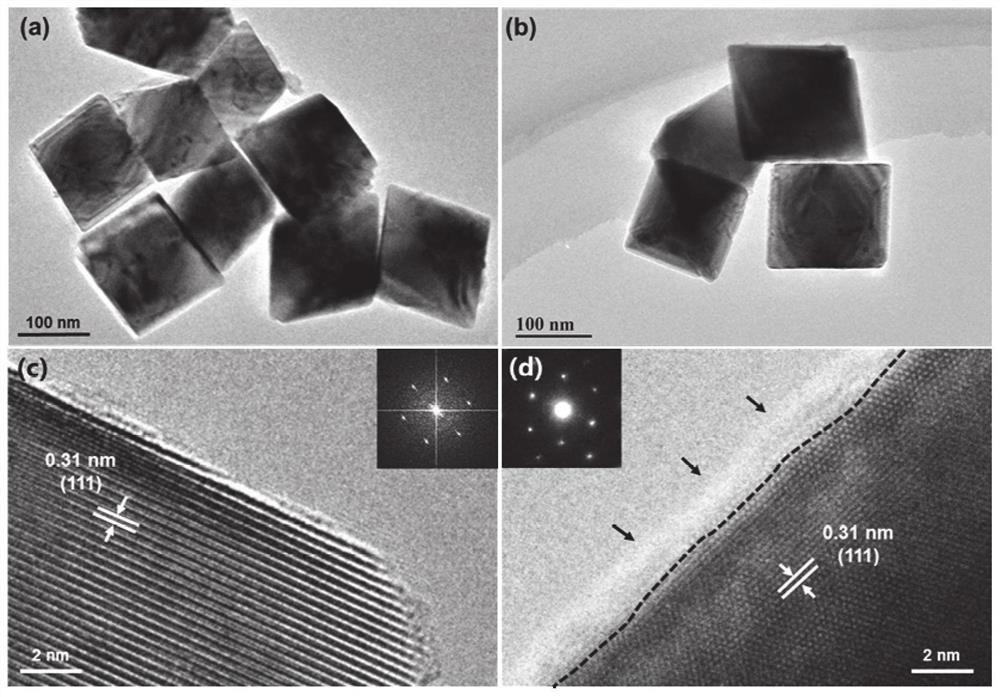

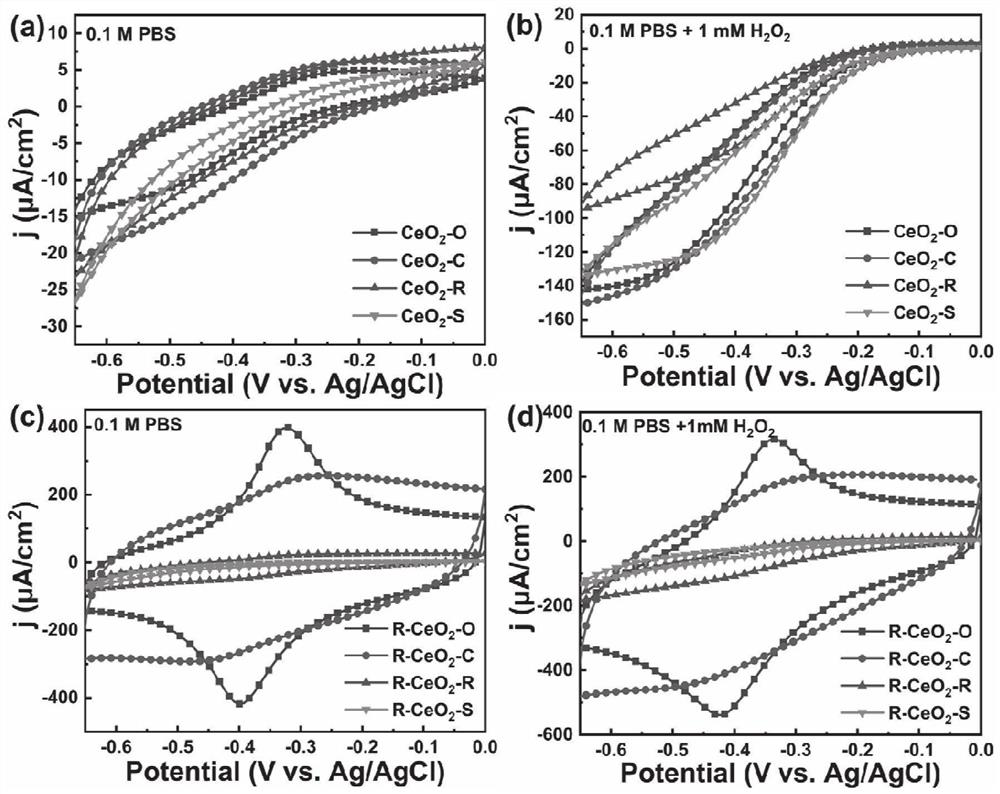

[0058] 1. Thermite reduction of octahedral CeO 2 Preparation of nanocrystalline electrode materials

[0059] a H 2 o 2 Enzyme-free electrochemical sensor electrodes using octahedral CeO after aluminothermic reduction 2 electrode material.

[0060] Preparation steps:

[0061] (1) Octahedral CeO 2 Preparation of Nanocrystalline Materials

[0062] First, 0.08mmol Na 3 PO 4 12H 2 O was dissolved in 64mL deionized water, and after complete dissolution, 8mmol Ce(NO 3 ) 3 ·6H 2 O, magnetically stirred for 1 h, and then the mixture was transferred to a 80 mL Teflon-lined stainless steel autoclave and kept in an oven at 160 °C for 24 h. After the hydrothermal reaction, the mixture at the bottom of the reactor was centrifuged and washed with deionized water and ethanol until neutral. Finally, it was dried in an oven at 80°C for 24h, and then calcined at 600°C at a rate of 2°C / min for 5h to obtain CeO with octahedral morphology. 2 sample.

[0063] (2) Thermite reduction of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com