A preparation method of mofs-coated highly conductive multi-walled carbon nanotube composites and its application in potassium-ion batteries

A technology of multi-walled carbon nanotubes and composite materials, which is applied in the field of anode materials for potassium ion batteries, can solve the problems of poor conductivity, volume expansion, poor cycle stability, and poor rate capability of CoO anodes, so as to reduce adsorption energy, improve solubility, and react The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

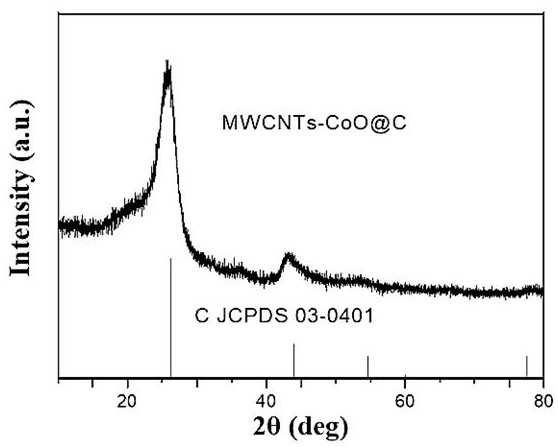

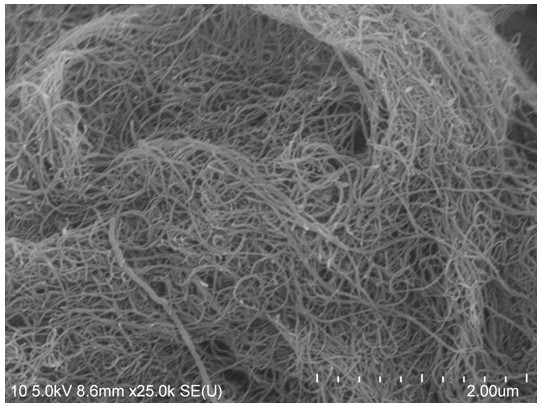

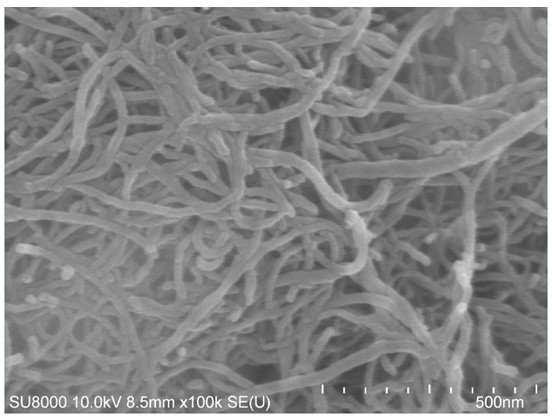

[0032] Preparation of MWCNTs-CoO@C Nanocomposites

[0033] Dissolve 3.2g of polyvinylpyrrolidone in a mixed solution of 110mL of absolute ethanol and secondary deionized water, and after it forms a clear solution, add 1g of multi-walled carbon nanotubes with oxygen-rich functional groups on the surface to ultrasonically disperse them , and then stirred to form a solution, followed by 1.5g C 4 h 6 CoO 4 Mixed with the above solution to obtain a mixed solution A. 2.0gC 10 h 6 o 8 Dissolve in a mixed solution of 110mL absolute ethanol and secondary deionized water to form a transparent solution B. Add solution B to solution A while stirring at a constant speed, place until the solution and precipitate are clearly separated, and then centrifuge to collect the black precipitate product. The product was washed with absolute ethanol to remove residual polyvinylpyrrolidone and C 4 h 6 o 4 2- , and then the obtained product was dried at 70 °C for 12 h to obtain the precursor ...

Embodiment 2

[0036] Preparation of MWCNTs-CoO@C Nanocomposites

[0037] Dissolve 4.0g of polyvinylpyrrolidone in a mixed solution of 110mL of absolute ethanol and secondary deionized water. After it forms a clear solution, 1.4g of multi-walled carbon nanotubes with oxygen-rich functional groups on the surface are added to it for ultrasonication. Disperse, then stir to form a solution, then 1.9g C 4 h 6 CoO 4 Mixed with the above solution to obtain a mixed solution A. 2.8gC 10 h 6 o 8 Dissolve in a mixed solution of 110mL absolute ethanol and secondary deionized water to form a transparent solution B. Add solution B to solution A while stirring at a constant speed, place until the solution and precipitate are clearly separated, and then centrifuge to collect the black precipitate product. The product was washed with absolute ethanol to remove residual polyvinylpyrrolidone and C 4 h 6 o 4 2- , and then the obtained product was dried at 75 °C for 10 h to obtain the precursor powder ...

Embodiment 3

[0040] Preparation of MWCNTs-CoO@C Nanocomposites

[0041] 4.8g of polyvinylpyrrolidone was dissolved in a mixed solution of 110mL of absolute ethanol and secondary deionized water, and after it formed a clear solution, 2.6g of multi-walled carbon nanotubes with oxygen-rich functional groups on the surface were added to it for ultrasonication. Disperse, then stir to form a solution, then 2.1g C 4 h 6 CoO 4 Mixed with the above solution to obtain a mixed solution A. 2.0gC 10 h 6 o 8 Dissolve in a mixed solution of 110mL absolute ethanol and secondary deionized water to form a transparent solution B. Add solution B to solution A while stirring at a constant speed, place until the solution and precipitate are clearly separated, and then centrifuge to collect the black precipitate product. The product was washed with absolute ethanol to remove residual polyvinylpyrrolidone and C 4 h 6 o 4 2- , and then the obtained product was dried at 80 °C for 11 h to obtain the precur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com