a ni 2 p 4 o 12 Nanoparticle material and its preparation method and application

A nanoparticle and nanocrystal technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of increasing time cost and process complexity, complicated operation process, high carbon layer annealing, etc., and achieve good catalytic stability Good stability, good dispersibility and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

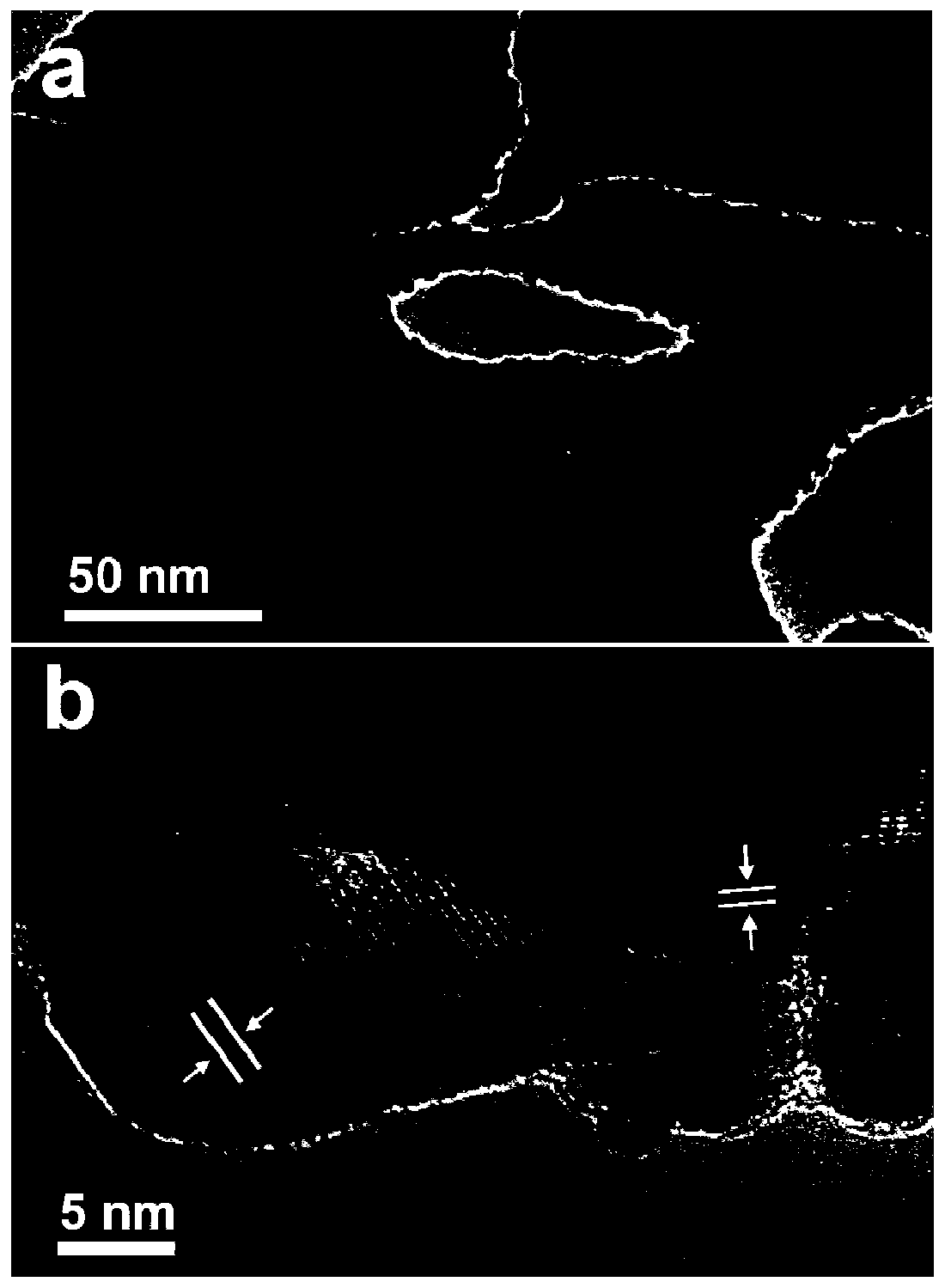

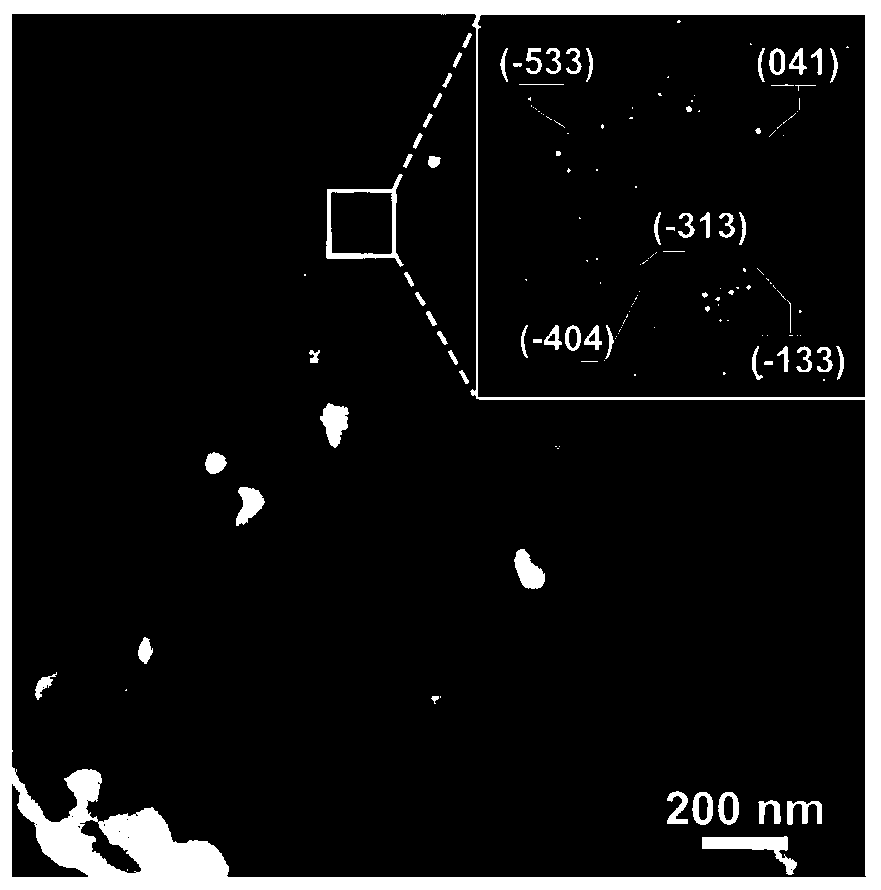

Image

Examples

Embodiment 1

[0034] A kind of Ni 2 P 4 o 12 The preparation method of nano particle material, comprises the following steps:

[0035]Step 1: Add nickel chloride hexahydrate and ammonium persulfate into deionized water at a molar ratio of 4:1, and mix evenly by ultrasonic to obtain a mixed solution A, and then add ammonia water to the mixed solution A to obtain a mixed solution B; Wherein, the concentration of Ni source is 0.25mol / L, and the volume ratio of mixed liquid A and ammonia water is 16:1;

[0036] Step 2: Put the carbon cloth into the mixture B prepared in step 1, and let it stand for 20 minutes for Ni(OH) 2 The growth of the nanosheet precursor, then take it out and wash it, and dry it naturally;

[0037] Step 3: Load Ni(OH) obtained in step 2 2 Put the carbon cloth into the heating center of the quartz tube, and place 1g of sodium hypophosphite containing crystal water in the upstream area of the quartz tube, 15cm away from the heating center;

[0038] Step 4: Vacuumize ...

Embodiment 2

[0043] Prepare Ni according to the steps of Example 1 2 P 4 o 12 For nanoparticle materials, only adjust the holding time of step 5 to 10 minutes, and keep other steps unchanged. The Ni that embodiment 2 prepares 2 P 4 o 12 The XRD diffraction patterns of nanoparticles are as follows: Figure 4 shown.

Embodiment 3

[0045] Prepare Ni according to the steps of Example 1 2 P 4 o 12 For nanoparticle materials, only adjust the amount of sodium hypophosphite containing crystal water in step 3 to 0.1 g, adjust the holding time at 300° C. in step 5 to 0 min, and keep other steps unchanged. The Ni that embodiment 3 prepares 2 P 4 o 12 The XRD diffraction pattern of the nanoparticle electrode is as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com