Preparation method of 2-undecylimidazoline

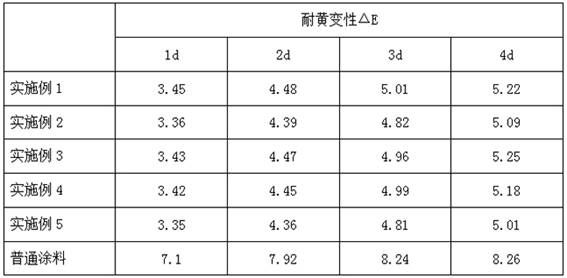

A technology of alkyl imidazoline and dodecyl aldehyde, applied in organic chemistry and other directions, can solve the problems of poor low-temperature baking and leveling, high melting point, poor yellowing resistance, etc., and achieve outstanding yellowing resistance. , Excellent storage performance, and the effect of increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of 2-undecyl imidazoline, comprising the following steps:

[0024] 1) Put 1 part of ethylenediamine and 0.01 part of N-bromosuccinimide in a 500ml flask, set the temperature in an ice-water bath to 5°C, start stirring for 30 minutes, then add 1 part of dodecylaldehyde dropwise, The dropwise addition is completed within 2 hours, and the resulting precipitate is poured into 1-2 parts of ethanol, 1-2 parts of ethyl acetate, 10-15 parts of acetone, and 1-2 parts of butyl acetate for stirring, and then filtered to obtain the intermediate product;

[0025] 2) Put the synthesized intermediate product into a single-necked flask, raise the temperature of the heat-conducting oil around the single-necked flask to 190°C, add 1 part of catalyst radium, nickel, and vacuumize for 2 hours, and dissolve the obtained product in ethanol solvent;

[0026] 3) After dissolving, remove the radium-nickel catalyst by filtration, the product is dissolved in the lower soluti...

Embodiment 2

[0029] A preparation method of 2-undecyl imidazoline, comprising the following steps:

[0030] 1) Put 1 part of ethylenediamine and 0.02 part of N-bromosuccinimide in a 500ml flask, set the temperature in an ice-water bath to 4°C, start stirring for 30 minutes, then add 1 part of dodecylaldehyde dropwise, After the dropwise addition was completed within 2 hours, the resulting precipitate was poured into 1 part of ethanol, 2 parts of ethyl acetate, 15 parts of acetone, and 2 parts of butyl acetate for stirring, and then filtered to obtain an intermediate product;

[0031] 2) Put the synthesized intermediate product into a single-necked flask, raise the temperature of the heat-conducting oil around the single-necked flask to 190°C, add 2 parts of catalyst Radium Linni, vacuumize for 2 hours, and dissolve the obtained product in ethanol solvent;

[0032] 3) After dissolving, remove the radium-nickel catalyst by filtration, the product is dissolved in the lower solution, and then ...

Embodiment 3

[0035] A preparation method of 2-undecyl imidazoline, comprising the following steps:

[0036] 1) Put 1 part of ethylenediamine and 0.03 part of N-bromosuccinimide in a 500ml flask, set the temperature in an ice-water bath to 6°C, start stirring for 30 minutes, then add 1 part of dodecylaldehyde dropwise, After the dropwise addition was completed within 2 hours, the resulting precipitate was poured into 2 parts of ethanol, 1 part of ethyl acetate, 15 parts of acetone, and 1 part of butyl acetate for stirring, and then filtered to obtain an intermediate product;

[0037] 2) Put the synthesized intermediate product into a single-necked flask, raise the temperature of the heat-conducting oil around the single-necked flask to 230°C, add 1 part of catalyst radium and nickel, vacuumize for 2 hours, and dissolve the obtained product in ethanol solvent;

[0038] 3) After dissolving, remove the radium-nickel catalyst by filtration, the product is dissolved in the lower solution, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com