Magnetic field annealing process for oriented silicon steel

A technology of magnetic field annealing and oriented silicon steel, applied in manufacturing tools, furnace types, furnaces, etc., can solve the problem of product grade, performance consistency and appearance need to be improved, grain boundary mobility recrystallization process delay, magnetic induction need to be further improved and other problems, to achieve the effect of changing the suspension, improving the magnetic properties, and reducing the iron loss of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

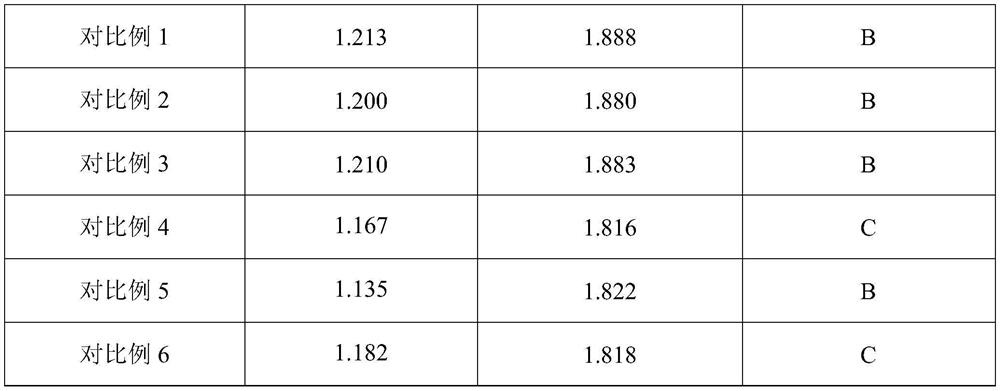

Examples

Embodiment 1

[0033] Preparation of the release agent: in parts by weight, the components of the release agent include MgO 8Mg(OH) 2 90 parts, 0.3 parts of citric acid, 2 parts of triammonium citrate, Na 2 B 4 o 7 5 parts, Sb 2 (SO 4 ) 3 2 parts, Al 2 o 3 3 parts, 2 parts of vinyltrimethoxysilane (A171), 3 parts of isopropyl triisostearyl titanate (TTS).

[0034] Preparation method: MgO 8Mg(OH) 2 Disperse in 5 times the mass of deionized water, stir at 5°C, add citric acid, triammonium citrate, Na 2 B 4 o 7 , Sb 2 (SO 4 ) 3 、Al 2 o 3 , vinyltrimethoxysilane (A171), isopropyl triisostearyl titanate (TTS), and stir evenly to make a coating solution for the isolation layer, and set aside.

[0035] A magnetic field annealing process for oriented silicon steel, comprising the following steps:

[0036] (1) After coating the release agent on the surface of the decarburization plate, nitrogen gas is introduced first, and then heated at a heating rate of 12°C / min under a nitroge...

Embodiment 2

[0043] Preparation of the release agent: in parts by weight, the components of the release agent include MgO 8Mg(OH) 2 80 parts, 0.1 parts of citric acid, 5 parts of triammonium citrate, Na 2 B 4 o 7 3 parts, Sb 2 (SO 4 ) 31 copy, Al 2 o 3 5 parts, 1 part of vinyltrimethoxysilane (A171), 1 part of isopropyl triisostearyl titanate (TTS).

[0044] Preparation method: MgO 8Mg(OH) 2 Disperse in 5 times the mass of deionized water, stir at 5°C, add citric acid, triammonium citrate, Na 2 B 4 o 7 , Sb 2 (SO 4 ) 3 、Al 2 o 3 , vinyltrimethoxysilane (A171), isopropyl triisostearyl titanate (TTS), and stir evenly to make a coating solution for the isolation layer, and set aside.

[0045] A magnetic field annealing process for oriented silicon steel, comprising the following steps:

[0046] (1) After coating the release agent on the surface of the decarburization plate, nitrogen gas is introduced first, and then heated at a heating rate of 10°C / min in a nitrogen atmosp...

Embodiment 3

[0053] Preparation of the release agent: in parts by weight, the components of the release agent include MgO 8Mg(OH) 2 100 parts, 0.5 parts of citric acid, 1 part of triammonium citrate, Na 2 B 4 o 7 8 parts, Sb 2 (SO 4 ) 3 5 parts, Al 2 o 3 1 part, 3 parts of vinyltrimethoxysilane (A171), 6 parts of isopropyl triisostearyl titanate (TTS).

[0054] Preparation method: MgO 8Mg(OH) 2 Disperse in 5 times the mass of deionized water, stir at 5°C, add citric acid, triammonium citrate, Na 2 B 4 o 7 , Sb 2 (SO 4 ) 3 、Al 2 o 3 , vinyltrimethoxysilane (A171), isopropyl triisostearyl titanate (TTS), and stir evenly to make a coating solution for the isolation layer, and set aside.

[0055] A magnetic field annealing process for oriented silicon steel, comprising the following steps:

[0056] (1) After coating the release agent on the surface of the decarburization plate, nitrogen gas is introduced first, and then heated at a heating rate of 15°C / min in a nitrogen at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com