A three-dimensional nonwoven material with controlled aroma release based on clamping heat convection multi-effect riveting technology and its preparation method and application

A technology of non-woven materials and heat convection, which is applied in the direction of non-woven fabrics, textiles, papermaking, fiber processing, etc., can solve the problems that hot melt adhesives do not conform to the concept of sustainable development, cumbersome and complicated procedures, and delamination, etc. Small accidental draft, improved efficiency and quality, high firmness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

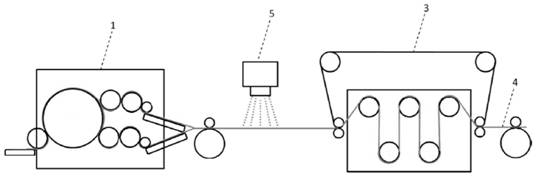

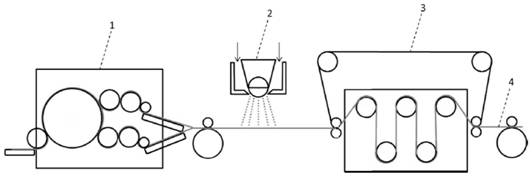

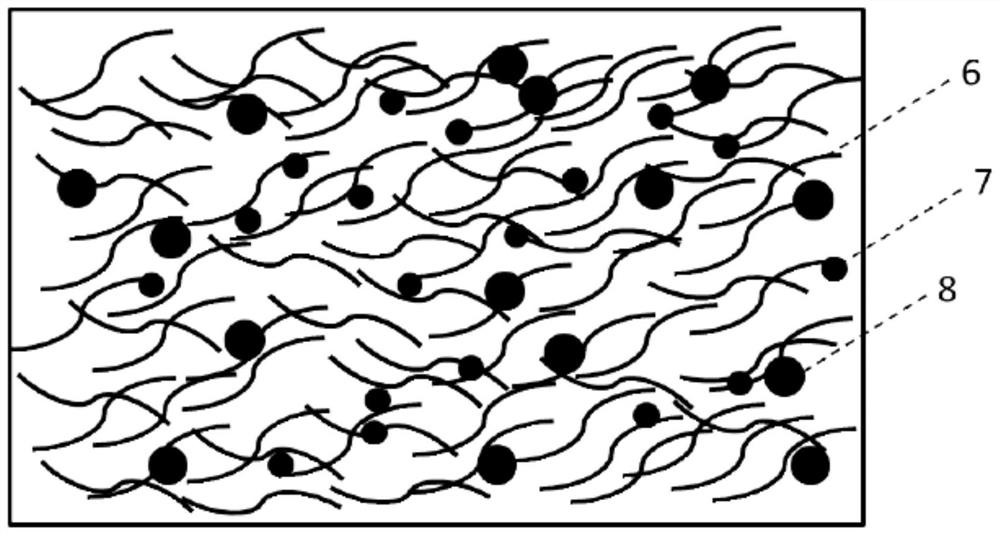

[0042] A preparation method of a three-dimensional nonwoven material with controlled fragrance release, comprising the following steps:

[0043] (1) Preparation of fiber web messy carding and forming. The corresponding hydrophobic hollow polyester fibers and hydrophobic ES (PE / PET) fibers were weighed in a mass ratio of 4:6. The two kinds of fiber raw materials are opened, mixed, antistatic treatment and carded to obtain a messy fiber web with a pore size of 100-150 μm. The carding adopts a single-cylinder double-doffer carding machine, and the cylinder speed is 303r / min and the doffer speed is 7.54. r / min, the rotation speed of the feeding roller is 0.76r / min, the rotation speed of the random roller is 6.03r / min, and the rotation speed of the winding roller is 10.73r / min.

[0044] (2) Wet homogeneous and aromatizing composite of disordered fiber network and aromatic micro-nanocapsules. At room temperature, the aromatic micro-nanocapsule emulsion (mL): deionized water (mL) =...

Embodiment 2

[0048] A preparation method of a three-dimensional nonwoven material with controlled fragrance release, comprising the following steps:

[0049] (1) Preparation of fiber web messy carding and forming. The corresponding hydrophobic hollow polyester fibers and hydrophobic ES (PE / PET) fibers were weighed in a mass ratio of 4:6. The two kinds of fiber raw materials are opened, mixed, antistatic treatment and carded to obtain a messy fiber web with a pore size of 100-150 μm. The carding adopts a single-cylinder double-doffer carding machine, and the cylinder speed is 303r / min and the doffer speed is 7.54. r / min, the rotation speed of the feeding roller is 0.76r / min, the rotation speed of the random roller is 6.03r / min, and the rotation speed of the winding roller is 10.73r / min.

[0050] (2) Wet homogeneous and aromatizing composite of disordered fiber network and aromatic micro-nanocapsules. At room temperature, use aromatic micro-nanocapsule emulsion (mL): deionized water (mL) =...

Embodiment 3

[0054] A preparation method of a three-dimensional nonwoven material with controlled fragrance release, comprising the following steps:

[0055] (1) Preparation of fiber web messy carding and forming. The corresponding hydrophobic hollow polyester fibers and hydrophobic ES bicomponent (PE / PET) fibers were weighed in a mass ratio of 4:6. The two kinds of fiber raw materials are opened, mixed, antistatic treatment and carded to obtain a messy fiber web with a pore size of 100-150 μm. The carding adopts a single-cylinder double-doffer carding machine, and the cylinder speed is 303r / min and the doffer speed is 7.54. r / min, the rotation speed of the feeding roller is 0.76r / min, the rotation speed of the random roller is 6.03r / min, and the rotation speed of the winding roller is 10.73r / min.

[0056] (2) Wet homogeneous and aromatizing composite of disordered fiber network and aromatic micro-nanocapsules. At room temperature, the aromatic micro-nanocapsule emulsion (mL): deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com