Lithium ion power battery cell matching method

A power battery, lithium-ion technology, applied in the field of lithium-ion power batteries, can solve the problems of insufficient vehicle cruising range, reduced single cell capacity, increased single cell production cost, etc., so as to improve the overall capacity and reduce internal consumption. , the effect of simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

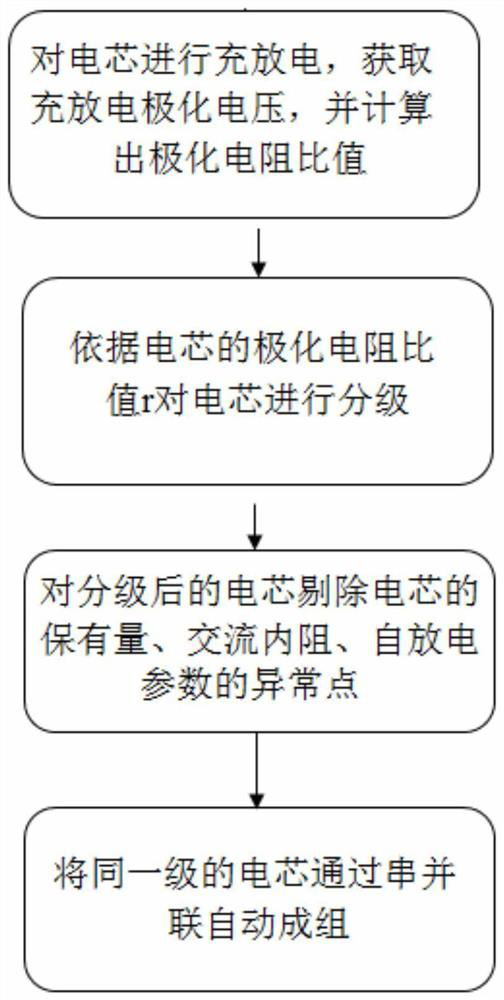

Method used

Image

Examples

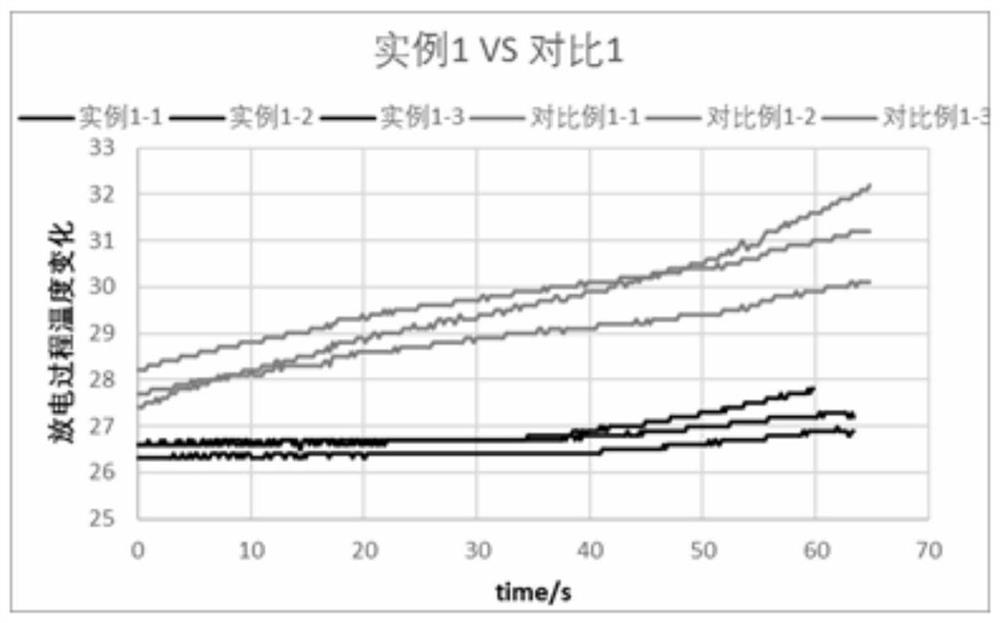

example 1

[0058] Example 1 [lithium iron phosphate - energy storage hard shell]

[0059] A method for assembling 100Ah lithium iron phosphate energy storage hard shell batteries, comprising the following steps:

[0060] (1) Do a special charge and discharge process for all the cells to be assembled, specifically follow the steps below:

[0061] (1-1) Stand still for 5 minutes;

[0062] (1-2) 50A constant current charging to 3.55V;

[0063] (1-3) Stand still for 5 minutes; and test the voltage V of the cell at this time 1 , V 1 All in the range of 3.35 ~ 3.38V;

[0064] (1-4) 10A constant current charging to 3.65V;

[0065](1-5) 3.65V constant voltage charging to 5A;

[0066] (1-6) Stand still for 5 minutes;

[0067] (1-7) 50A constant current discharge to 2.7V;

[0068] (1-8) Stand still for 5 minutes; and test the voltage V of the cell at this time 2 , V 2 Both are in the range of 2.60~2.90V;

[0069] (1-9) 10A constant current discharge to 2.5V;

[0070] (1-10) stand still...

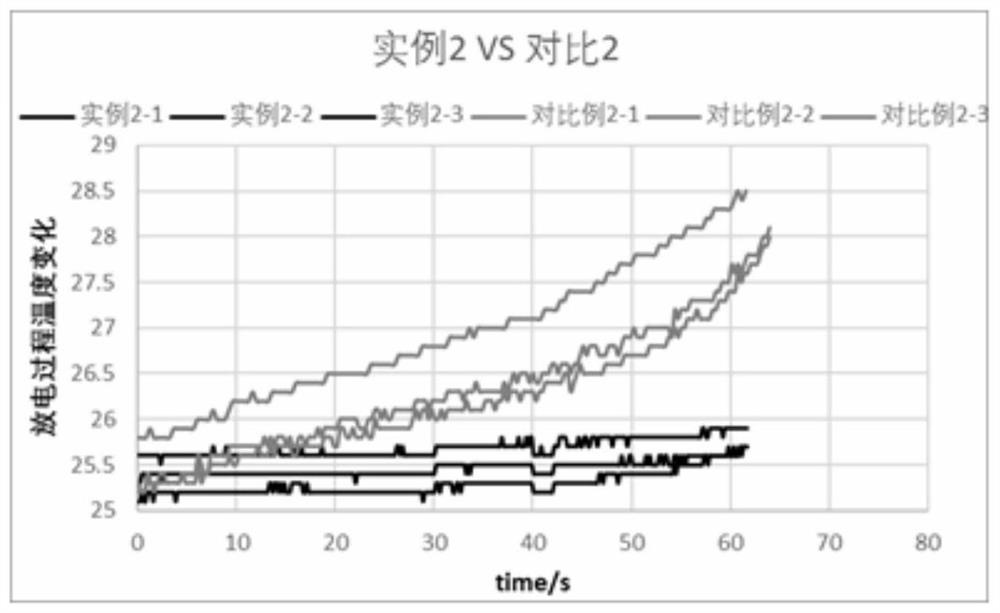

example 2

[0076] Example 2 [nickel cobalt lithium manganese oxide - power soft package]

[0077] A 40Ah nickel-cobalt-manganese lithium manganese oxide power soft-pack battery assembly method comprises the following steps:

[0078] (1) Do a special charge and discharge process for all the cells to be assembled, specifically follow the steps below:

[0079] (1-1) Stand still for 5 minutes;

[0080] (1-2) 20A constant current charging to 4.0V;

[0081] (1-3) Stand still for 5 minutes; and test the voltage V of the cell at this time 1 , V 1 All in the range of 3.7 ~ 3.85V;

[0082] (1-4) 4A constant current charging to 4.2V;

[0083] (1-5) 4.2V constant voltage charging to 2A;

[0084] (1-6) Stand still for 5 minutes;

[0085] (1-7) 20A constant current discharge to 3.0V;

[0086] (1-8) Stand still for 5 minutes; and test the voltage V of the cell at this time 2 , V 2 All in the range of 3.1 ~ 3.3V;

[0087] (1-9) 4A constant current discharge to 2.8V;

[0088] (1-10) stand sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com