Coating material for light-weight lithium ion battery diaphragm, preparation method of coating material and light-weight lithium ion battery composite diaphragm

A technology of lithium ion battery and coating material, which is applied in the field of coating material for lightweight lithium ion battery separator and its preparation, and the field of lightweight lithium ion battery composite separator, which can solve the problem of small air permeability, separator peel strength, thermal stability There is no research and other issues to achieve the effect of light and thin coating, improved wettability and stability, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

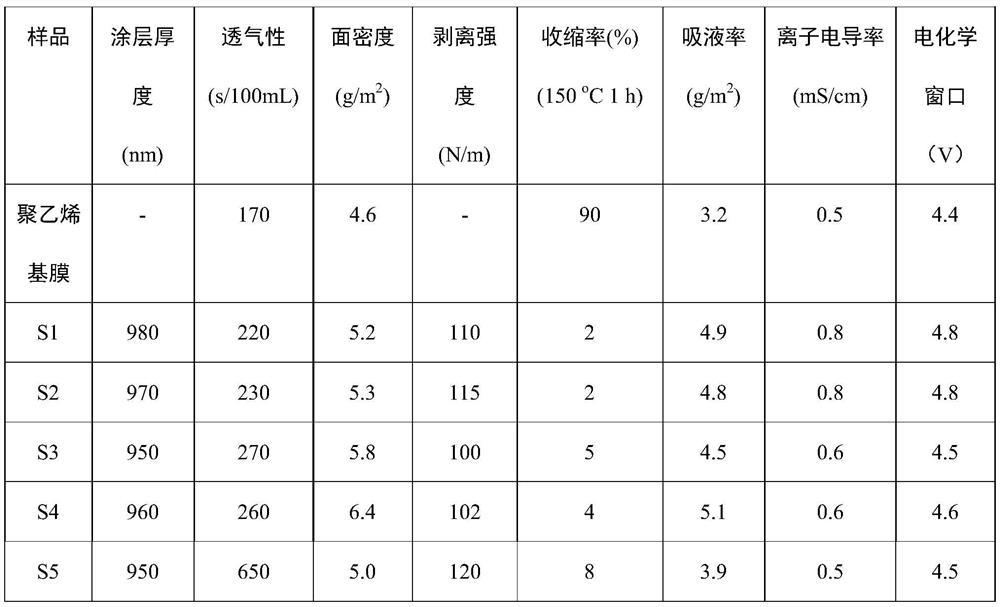

Embodiment 1

[0043] This embodiment provides a coating material for a lightweight lithium-ion battery diaphragm, and its preparation method is as follows:

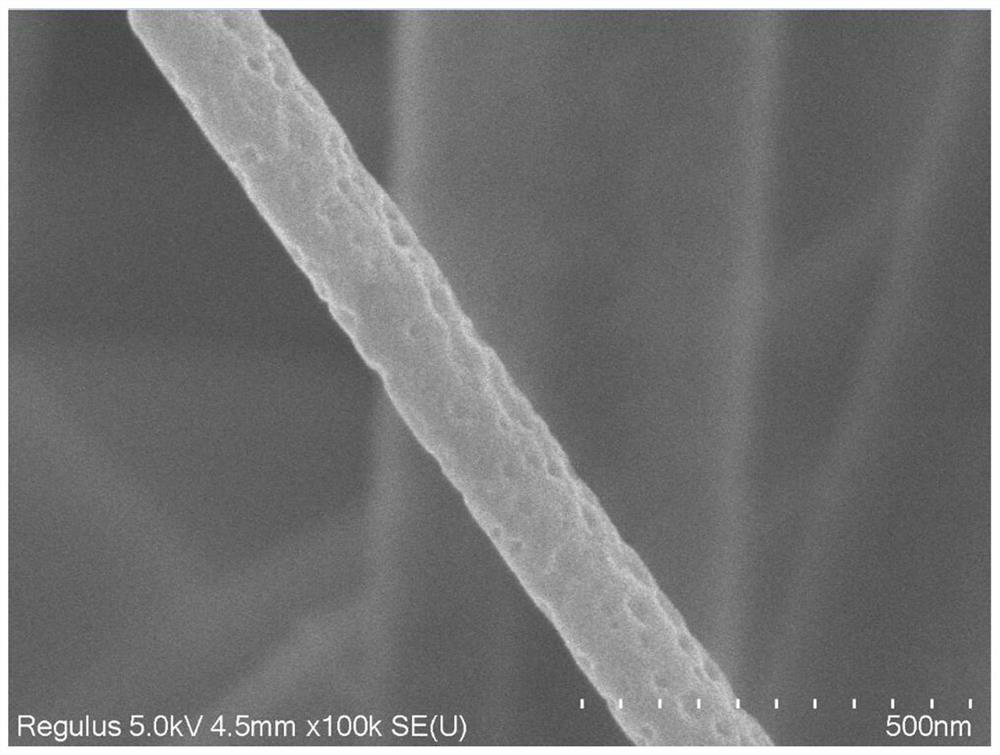

[0044] Disperse 160g of nanocellulose with a diameter of 50nm (d50=50nm) and a length of 2 μm in 5kg of deionized water, stir and disperse for later use; 160g of porous inorganic SiO 2 Disperse the nanofibers in 5kg of deionized water, add 0.1wt% polyvinyl alcohol (alcoholysis degree: 99mol%, viscosity: 28mPa.s), stir and homogenize at high speed for 5h, and stir and mix with the nanocellulose slurry to obtain .

[0045] Among them, porous inorganic SiO 2 The nanofibers were prepared as follows:

[0046] 10g of polyvinyl alcohol (PVA) powder was dissolved in 90g of distilled water, stirred at 80°C for 1h, then cooled at room temperature for 12h to obtain a 10wt% PVA solution; mixed 15ml of tetraethyl orthosilicate and distilled water, Stir evenly with magnetic force, and then add 100 μL of phosphoric acid (H 3 PO 4 ), stirred at r...

Embodiment 2

[0052] This embodiment provides a coating material for a lightweight lithium-ion battery diaphragm, and its preparation method is as follows:

[0053] Disperse 160g of nanocellulose with a diameter of 50nm (d50=50nm) and a length of 2 μm in 5kg of deionized water, stir and disperse for use; 160g of porous inorganic Al 2 o 3 Disperse the nanofibers in 5kg of deionized water, add 0.1wt% polyvinyl alcohol (alcoholysis degree: 99mol%, viscosity: 28mPa.s), stir and homogenize at high speed for 5h, and stir and mix with the nanocellulose slurry to obtain .

[0054] Among them, porous inorganic Al 2 o 3 The nanofibers were prepared as follows:

[0055] Dissolve 10g of polyvinyl alcohol (PVA) powder in 90g of distilled water, stir at 80°C for 1h, then cool at room temperature for 12h to obtain a 10wt% PVA solution; mix 10g of nano-alumina with 50ml of distilled water, and magnetically stir homogeneous, and then add 100 μL of phosphoric acid (H 3 PO 4 ), stirred at room temperat...

Embodiment 3

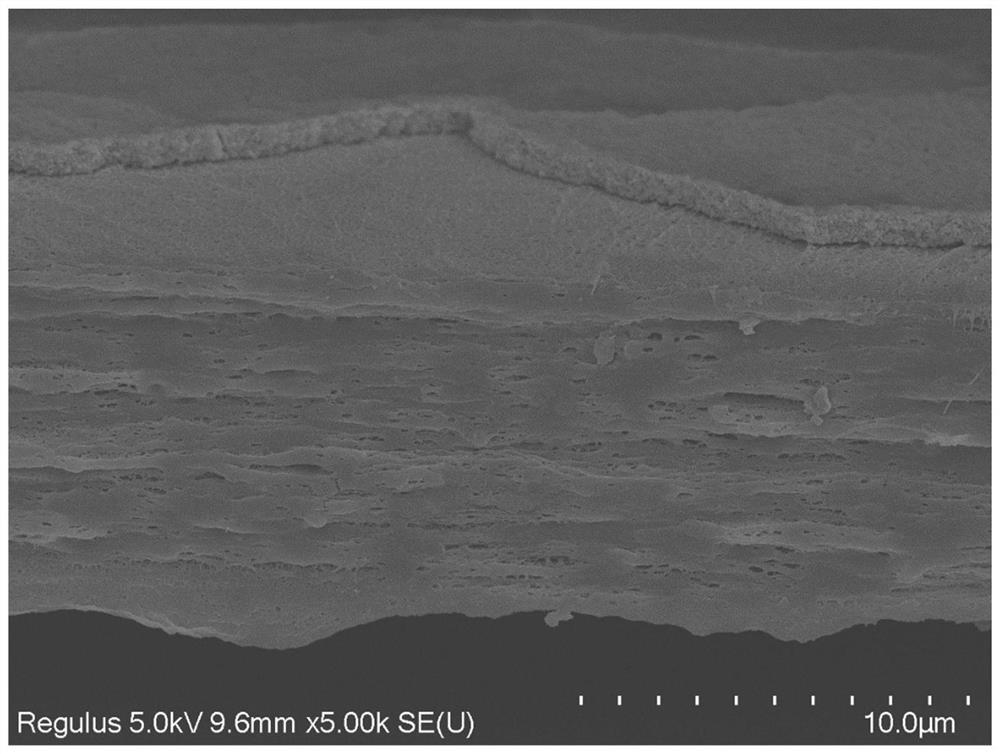

[0060] This embodiment provides a lithium-ion battery composite diaphragm, the preparation method of which is as follows:

[0061] Put 50g of alumina with a particle size of 100nm in 250ml of water, then add 250ml of 2mol / L NaOH solution, stir at 90°C for 3 hours, centrifuge, wash, and dry to obtain inorganic nanoparticles with a microporous structure;

[0062] Disperse 16g of nanocellulose with a diameter of 50nm (d50=50nm) and a length of 2 μm in 500g of deionized water, stir and disperse for use; disperse the prepared 16g of porous inorganic particles in 500g of deionized water, add 0.1wt% polyethylene Alcohol (degree of alcoholysis: 99mol%, viscosity: 28mPa.s), after high-speed stirring and homogenization for 5 hours, stir and mix with nanocellulose slurry;

[0063] Prepare a polyethylene porous membrane with a thickness of 9 μm;

[0064] The slurry prepared above was coated on both sides of the porous membrane at a coating rate of 60 m / min, and then dried in an oven at 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com