A carbon fiber toughened ultra-high temperature ceramic matrix composite material that avoids thermal mismatch and its preparation method

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of carbon fiber toughened ultra-high temperature ceramic matrix composite materials and its preparation, can solve problems such as performance degradation of composite materials, improve thermal shock resistance, improve mechanical properties, and avoid oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

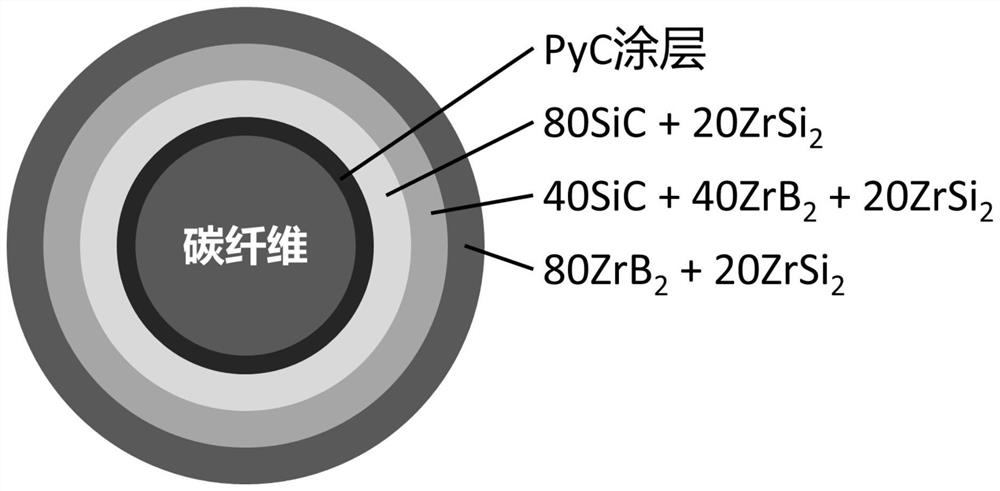

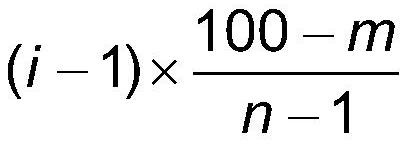

[0032] A carbon fiber toughened ultra-high temperature ceramic matrix composite material that avoids thermal mismatch. In the cross-sectional direction of the carbon fiber, there are n layers of gradient ceramic substrates with carbon fiber as the center and the thermal expansion coefficient gradually increases from the inside to the outside. The innermost ceramic substrate The raw materials include silicon carbide and zirconium disilicide; the raw materials of the outermost ceramic matrix include diboride ultra-high temperature ceramics and zirconium disilicide; the ceramic matrix raw materials of the middle layer include: diboride ultra-high temperature ceramics, silicon carbide, and zirconium disilicide; The diboride ultra-high temperature ceramic mentioned above is zirconium diboride; the volume of the carbon fiber toughened ultra-high temperature ceramic matrix composite is 100 parts, and the volume part of the carbon fiber is 40; The volume is 100 parts, the volume part o...

Embodiment 2

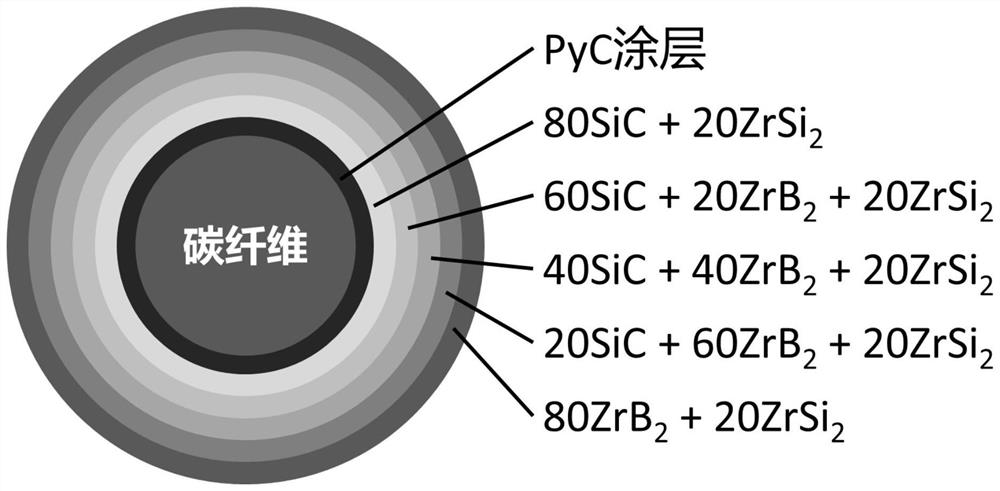

[0044] The difference between this example and Example 1 is that n=5; i=1, 2, 3, 4, 5; in step 4), the electrophoretic deposition time is 12 minutes. Such as figure 2 As shown, 5 layers of radially gradient ceramic coatings were coated on carbon fibers using electrophoretic deposition technology.

Embodiment 3

[0046] The difference between this example and Example 1 is that the diboride ultra-high temperature ceramic is hafnium diboride; based on 100 parts of carbon fiber toughened ultra-high temperature ceramic matrix composite material, the volume part of carbon fiber is 30; m=30 ; n=5; i=1, 2, 3, 4, 5; in step 4), the electrophoretic deposition time is 14 min.

[0047] To sum up, a carbon fiber toughened ultra-high temperature ceramic matrix composite material that avoids thermal mismatch of the present invention solves the problem of thermal mismatch between carbon fiber and matrix, improves the mechanical properties of the composite material, and avoids the composite material’s resistance to oxidation and anti-oxidation. The decline of ablation performance; the designed gradient ceramic matrix improves the fracture resistance and thermal shock resistance of the composite material; the pyrolytic carbon derived from the polymer reacts with zirconium disilicide to generate nano-sca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com