Polybutadiene latex, preparation method thereof and ABS (Acrylonitrile Butadiene Styrene) resin

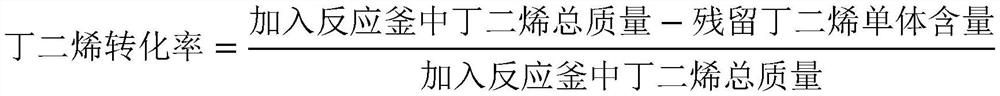

A technology of polybutadiene latex and butadiene conversion rate, which is applied in the field of polymers, can solve problems such as complex preparation processes, and achieve the effect of improving impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take respectively 4g of perfluorohexyl ethyl acrylate, 3g of methyl acrylate, 100g of butadiene, 2g of potassium persulfate, 2g of ammonium persulfate, 4g of potassium carbonate, 3g of potassium hydroxide, 1g of sodium naphthalenesulfonic acid formaldehyde condensate, Add 2g of sodium dodecylbenzenesulfonate, 0.5g of n-dodecyl mercaptan, and 196g of water into the reactor and mix them uniformly, and heat up to 85°C for polymerization; chromatographic analysis and calculation show that when the conversion rate of butadiene is 69.6 %, add 4 g of cyclohexyl methacrylate to carry out copolymerization reaction, and obtain polybutadiene latex when the conversion rate of butadiene is 98.3%.

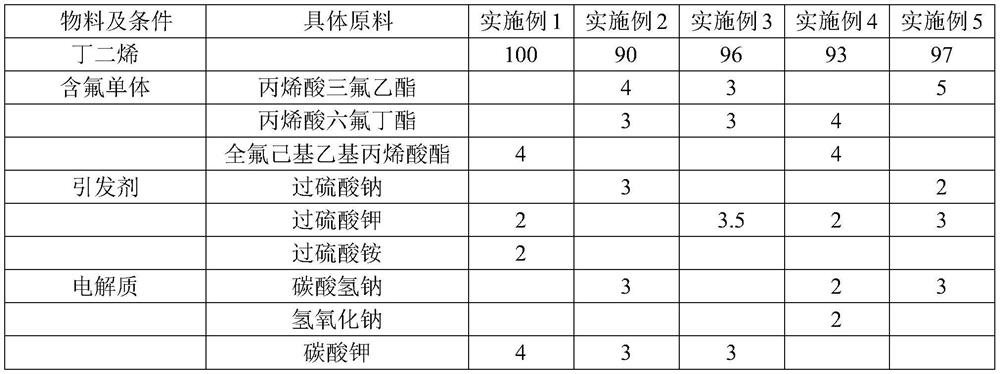

[0038] The differences between Examples 2-5 and Example 1 are shown in Table 1, and the rest of the raw materials, experimental conditions and reaction steps are the same as in Example 1.

[0039] The difference between table 1 embodiment 2-5 and embodiment 1

[0040]

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

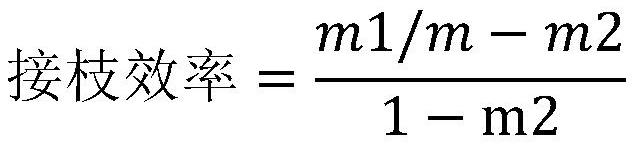

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap