Inorganic paint with air purification function and preparation method thereof

An inorganic coating and air purification technology, applied in the field of coatings, can solve the problems of negative oxygen ion catalysis and unimproved excitation continuity, and achieve the effect of increasing utilization rate, increasing concentration, and efficiently purifying the air environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

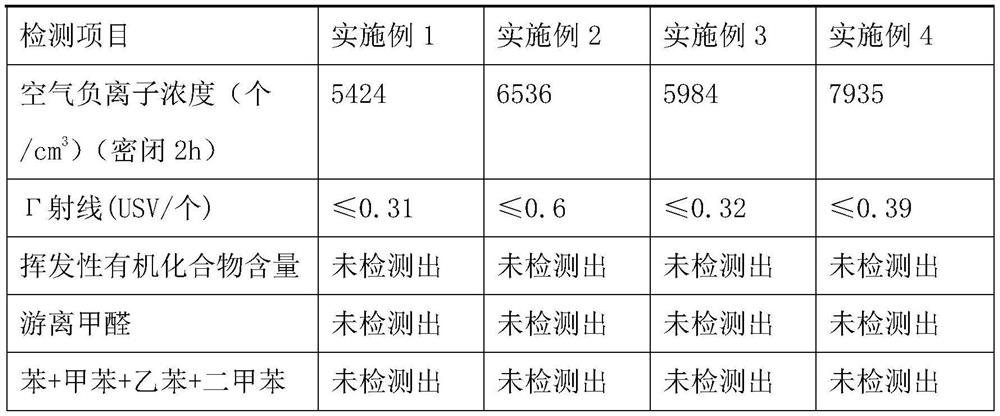

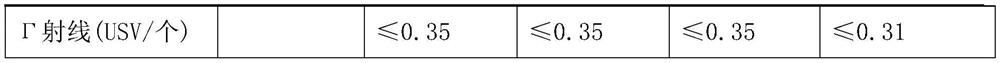

Examples

Embodiment 1

[0033] An inorganic coating with air purification function, comprising the following components, in parts by weight: 40 parts of silicate, 40 parts of calcium carbonate powder, 10 parts of silica sol, 5 parts of talcum powder, 1 part of kaolin, and attapulgite 1 part, 1 part of alumina, 1 part of nano-silica, 1 part of modified tourmaline rare earth ternary composite material;

[0034] The modified tourmaline rare earth ternary composite material includes mineral carrier with adsorption and porous structure, tourmaline powder and catalyst ceria.

[0035] In this embodiment, the mineral carrier is sepiolite of 600-800 mesh.

[0036] In this implementation, the preparation method of the modified tourmaline rare earth ternary composite material includes:

[0037] (1) preparation concentration is the urea aqueous solution of 20g / L, for subsequent use;

[0038] (2) cerium dioxide sol is obtained by mixing cerium nitrate and urea aqueous solution, and the concentration of the obta...

Embodiment 2

[0045] An inorganic coating with air purification function, comprising the following components, in parts by weight: 60 parts of silicate, 20 parts of calcium carbonate powder, 30 parts of silica sol, 15 parts of talcum powder, 5 parts of kaolin, and attapulgite 5 parts, 5 parts of alumina, 5 parts of nano-silica, 10 parts of modified tourmaline rare earth ternary composite material;

[0046] The modified tourmaline rare earth ternary composite material includes mineral carrier with adsorption and porous structure, tourmaline powder and catalyst ceria.

[0047] In this embodiment, the mineral carrier is 600-800 mesh diatom mud.

[0048] In this implementation, the preparation method of the modified tourmaline rare earth ternary composite material includes:

[0049] (1) preparation concentration is the urea aqueous solution of 50g / L, standby;

[0050] (2) cerium dioxide sol is obtained by mixing cerium nitrate and urea aqueous solution, and the concentration of the obtained cer...

Embodiment 3

[0057] An inorganic coating with air purification function, comprising the following components, in parts by weight: 50 parts of silicate, 20 parts of calcium carbonate powder, 20 parts of silica sol, 10 parts of talcum powder, 5 parts of kaolin, and attapulgite 5 parts, 2 parts of alumina, 5 parts of nano-silica, 5 parts of modified tourmaline rare earth ternary composite material;

[0058] The modified tourmaline rare earth ternary composite material includes mineral carrier with adsorption and porous structure, tourmaline powder and catalyst ceria.

[0059] In this embodiment, the mineral carrier is porous graphene.

[0060] In this implementation, the preparation method of the modified tourmaline rare earth ternary composite material includes:

[0061] (1) preparation concentration is the urea aqueous solution of 40g / L, standby;

[0062] (2) cerium oxide sol is prepared by mixing cerium nitrate and urea aqueous solution, and the concentration of the obtained cerium oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com