A kind of non-tin catalyzed silane-modified polyether sealant and preparation method thereof

A silane-modified polyether, non-tin-catalyzed silane technology, applied in polyether adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problem of neglecting the control of sealant curing speed and surface drying time. , to achieve the effect of moderate curing speed and surface drying time, conducive to construction and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

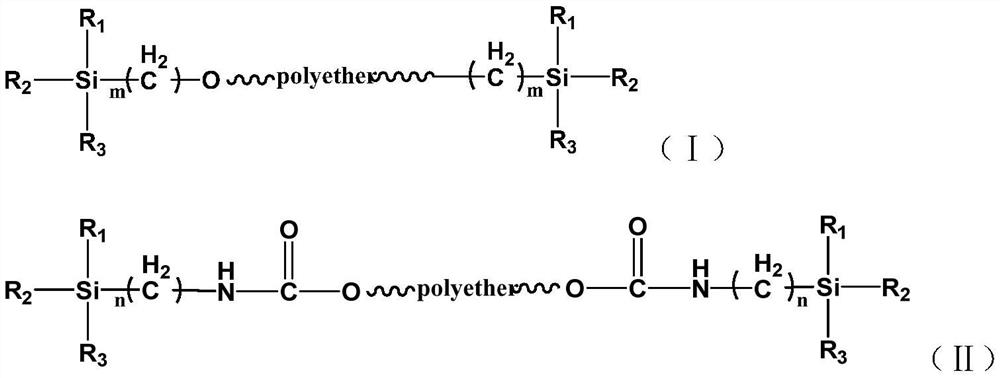

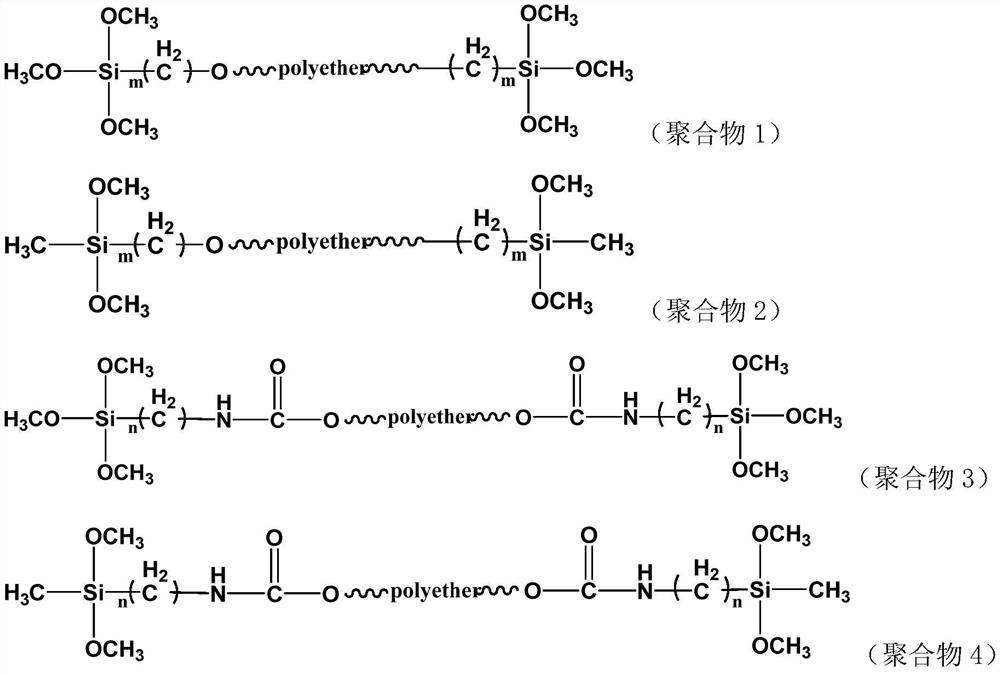

[0058] The structure of silane modified polyether polymer is as follows:

[0059]

[0060] Put the pre-treated allyl-terminated polyether with a molecular weight of 12000 (Hangzhou Danwei Technology Co., Ltd., AEA series) and methyldimethoxysilane into a four-necked flask at a molar ratio of 1:2, and then add 15ppm chlorine Platinum acid catalyst, feed nitrogen and start stirring, heat up to 80°C and react for 5 hours. After the reaction, reduce the pressure to -0.09MPa, and evaporate under reduced pressure at 80°C for 0.5 hours to prepare silane-modified polyether polymer Ⅰ .

preparation example 2

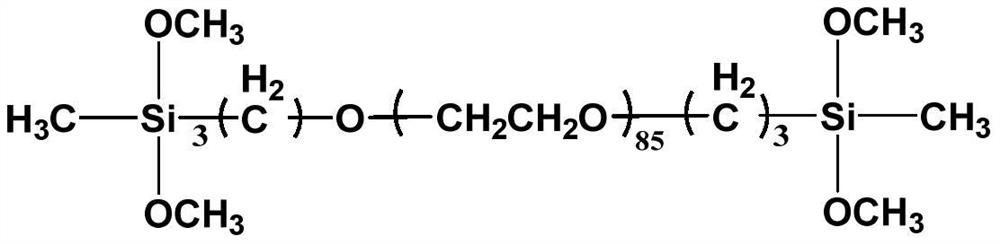

[0062] The structure of silane modified polyether polymer is as follows:

[0063]

[0064] Put the pretreated allyl-terminated polyether with a molecular weight of 12000 (Hangzhou Danwei Technology Co., Ltd., AEA series) and trimethoxysilane into the four-necked flask according to the molar ratio of 1:2, and then add 15ppm chloroplatinic acid catalyst , feed nitrogen and start stirring, heat up to 80°C and react for 5 hours. After the reaction, reduce the pressure to -0.09MPa, and evaporate under reduced pressure at 80°C for 0.5 hour to prepare silane-modified polyether polymer II.

preparation example 3

[0066] The structure of silane modified polyether polymer is as follows:

[0067]

[0068] Dehydrate and degas 100 parts of polyethylene glycol with a molecular weight of 16000 under vacuum conditions at 110°C for 2 hours, cool down to 60°C, and add isocyanate propylmethyldimethoxysilane in sequence (so that the molar ratio of isocyanate to hydroxyl is 1:1), triethylamine (accounting for 0.1% of the mass of polyethylene glycol), high-purity nitrogen gas was introduced as a reaction protective gas, stirred evenly, and reacted at 90°C for 1 hour to obtain silane-modified polyether polymer III .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com