Preparation method and application of room-temperature phosphorescent carbon-based composite material capable of changing color under single excitation source

A carbon-based composite material and room temperature phosphorescence technology, which is applied in the direction of luminescent materials, applications, chemical instruments and methods, etc., can solve the problems of complex preparation or purification, limited application, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

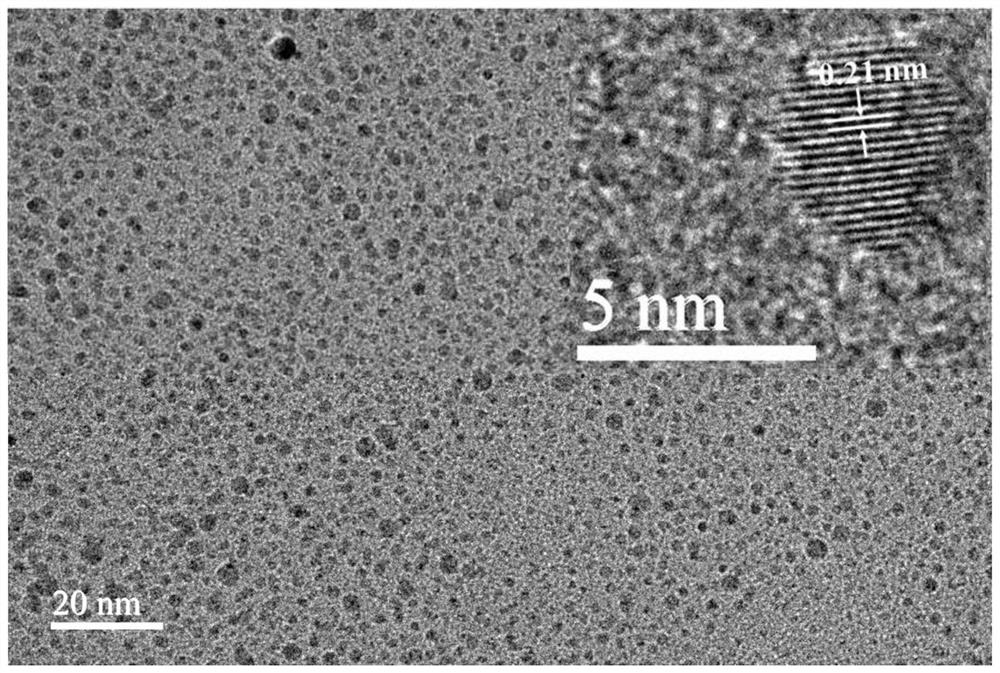

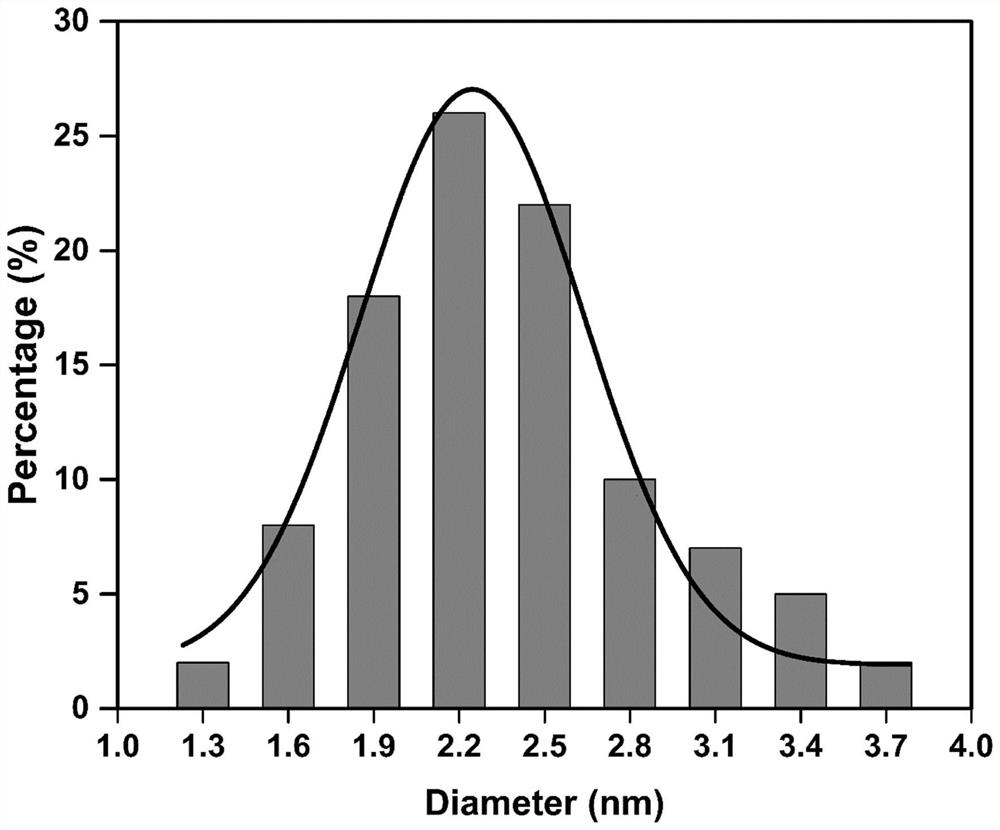

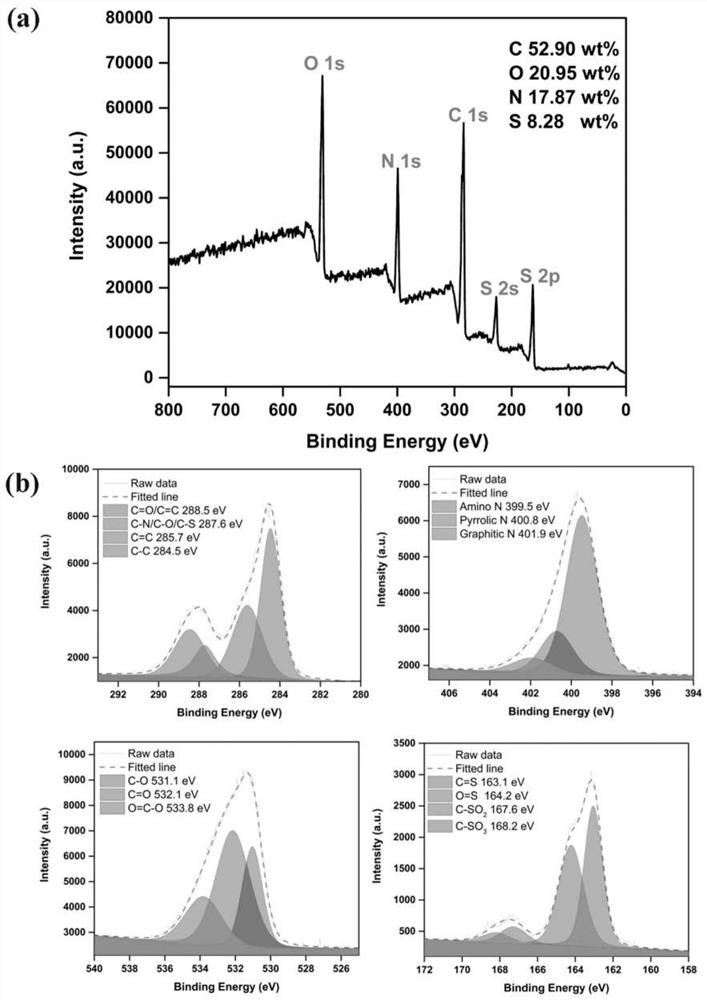

[0049]Weigh 0.2522g of melamine and 0.4802g of cystine into 15mL of water, stir for 10min, transfer the mixture to a 25mL reactor, seal it, put it in an oven, set the temperature at 180°C for 4h. After the reaction, it was naturally cooled to room temperature, centrifuged at 10000r / min at high speed, and the obtained clear liquid was refrigerated at 4°C for 12 hours, then centrifuged at 10000r / min at high speed, dialyzed with a dialysis bag (3500D), and freeze-dried at -55°C, the obtained powder was Yellow fluorescent emitting carbon quantum dots. Then weigh 0.0450g of the above-mentioned carbon quantum dots and disperse them in 30mL of water, add 0.3000g of melamine, heat up to 100°C and reflux for 2 hours to carry out self-assembly, naturally cool down after the reaction, massive crystals are precipitated, washed with water, filtered, and vacuum-dried at 50°C, the obtained That is, the target carbon-based compound with a yield of 75.3%. Excited by a 365nm ultraviolet light ...

Embodiment 2

[0052] Weigh 0.2522g of melamine and 0.4802g of cystine into 15mL of water, stir for 10min, transfer the mixture to a 25mL reactor, seal it, put it in an oven, set the temperature at 180°C for 4h. After the reaction, it was naturally cooled to room temperature, centrifuged at 10000r / min at high speed, and the obtained clear liquid was refrigerated at 4°C for 12 hours, then centrifuged at 10000r / min at high speed, dialyzed with a dialysis bag (3500D), and freeze-dried at -55°C, the obtained powder was Yellow fluorescent emitting carbon quantum dots. Then weigh 0.0450g of the above-mentioned carbon quantum dots and disperse them in 30mL of water, add 0.4500g of isophthalic acid, heat up to 120°C and reflux for 2h to carry out self-assembly, naturally cool down after the reaction, needle-shaped crystals precipitate, wash with water, filter, vacuum at 50°C After drying, the target carbon-based composite was obtained with a yield of 90.7%. Excited by a 365nm ultraviolet lamp and t...

Embodiment 3

[0055] Weigh 0.2522g of melamine and 0.4802g of cystine into 15mL of water, stir for 10min, transfer the mixture to a 25mL reactor, seal it, put it in an oven, set the temperature at 180°C for 4h. After the reaction, it was naturally cooled to room temperature, centrifuged at 10000r / min at high speed, and the obtained clear liquid was refrigerated at 4°C for 12 hours, then centrifuged at 10000r / min at high speed, dialyzed with a dialysis bag (3500D), and freeze-dried at -55°C, the obtained powder was Yellow fluorescent emitting carbon quantum dots. Then weigh 0.0450g of the above-mentioned carbon quantum dots and disperse them in 30mL of water, add 0.4500g of phthalic acid, heat up to 120°C and reflux for 2h to carry out self-assembly, naturally cool down after the reaction, needle-shaped crystals precipitate, wash with water, filter, vacuum at 50°C After drying, the target carbon-based composite was obtained with a yield of 89.8%. Such as Image 6 After being excited by a 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com