A microalloyed plate with high strength and toughness and good metallurgical quality in the core and its preparation method

A micro-alloying and quality technology, applied in the field of hot-rolled steel, can solve the problems of shortening the process flow, reducing the hydrogen embrittlement sensitivity of the core of the steel plate, and achieving the effects of improving production efficiency, improving the pass rate of flaw detection, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

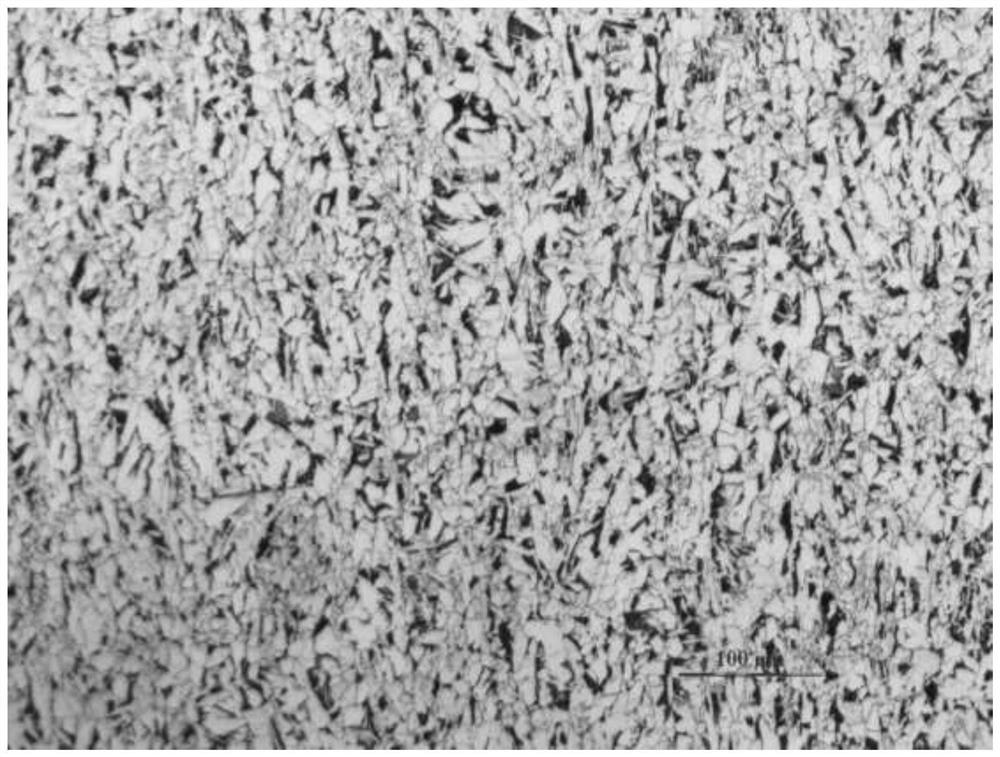

[0055] A micro-alloyed plate with high strength and toughness and good metallurgical quality in the core. It is a micro-alloyed plate with a thickness of 30mm prepared by the economical hydrogen content control and hydrogen elimination TMCP process, and its chemical composition is distributed according to mass percentage For: C: 0.16%, Si: 0.1%, Mn: 1.1%, P: 0.014%, S: 0.003%, Cr: 0.05%, Nb: 0.005%, V: 0.09%, Mo: 0.06%, N: 0.012 %, the balance is Fe and unavoidable impurities, and the metallographic structure of the microalloyed plate with high strength and toughness and good metallurgical quality in the core is 75% acicular ferrite, 15% granular bainite and volume Percentage 10% pearlite; see its microstructure figure 1 .

[0056] The preparation method of the microalloyed medium-thick plate with high strength and toughness and good metallurgical quality in the core is as follows:

[0057] (1) Converter steelmaking: steel scrap and charge are baked and dried, the temperatur...

Embodiment 2

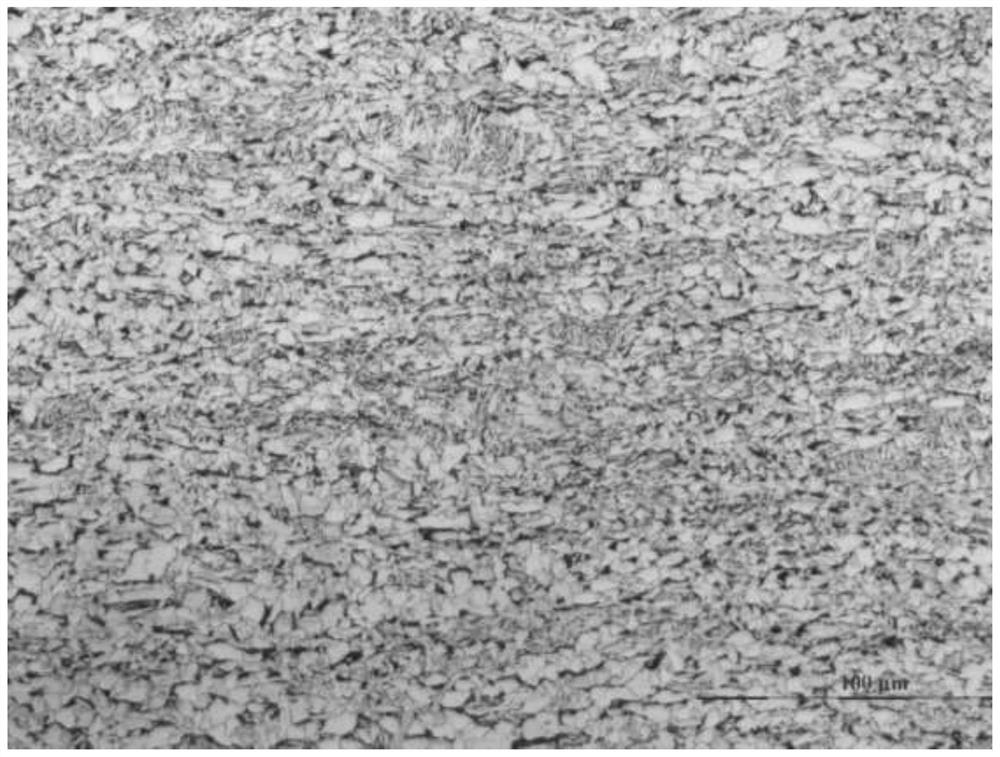

[0066] A micro-alloyed plate with high strength and toughness and good metallurgical quality in the core. It is a micro-alloyed plate with a thickness of 50mm prepared by the economical hydrogen content control and hydrogen elimination TMCP process, and its chemical composition is distributed according to mass percentage For: C: 0.12%, Si: 0.2%, Mn: 1.7%, P: 0.013%, S: 0.002%, Cr: 0.15%, Nb: 0.015%, V: 0.10%, Mo: 0.08%, N: 0.015 %, the balance is Fe and unavoidable impurities, and the metallographic structure of the microalloyed plate with high strength and toughness and good metallurgical quality in the core is 78% acicular ferrite and 22% granular bainite; See the microstructure figure 2 .

[0067] The preparation method of the microalloyed medium-thick plate with high strength and toughness and good metallurgical quality in the core is as follows:

[0068] (1) Converter steelmaking: Scrap steel and charge are baked and dried, the temperature of molten iron is 1255°C and ...

Embodiment 3

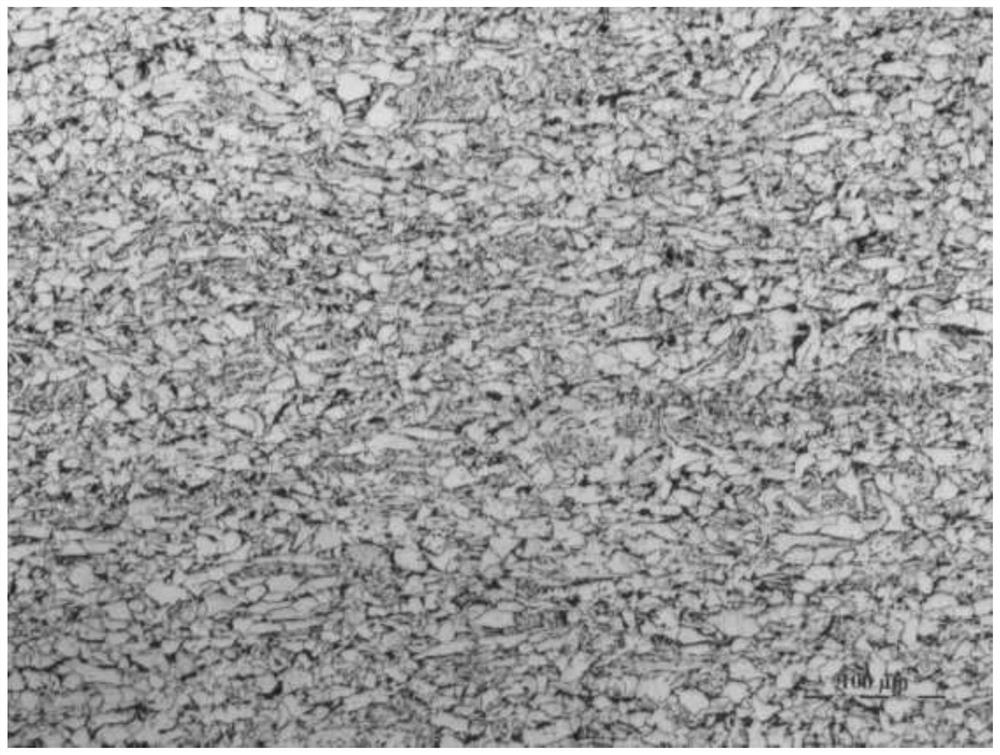

[0077] A micro-alloyed medium-thick plate with high strength and toughness and good metallurgical quality in the core. It is a micro-alloyed medium-thick plate with a thickness of 80mm prepared by economical hydrogen content control and hydrogen elimination TMCP process, and its chemical composition is distributed according to mass percentage For: C: 0.09%, Si: 0.25%, Mn: 1.85%, P: 0.013%, S: 0.001%, Cr: 0.15%, Nb: 0.025%, Mo: 0.07%, V: 0.18%, N: 0.018 %, the balance is Fe and unavoidable impurities, the metallographic structure of the microalloyed plate with high strength and toughness and good metallurgical quality in the core is 80% acicular ferrite and 20% bainite, which is obviously See microstructure diagram image 3 ;

[0078] The preparation method of the microalloyed medium-thick plate with high strength and toughness and good metallurgical quality in the core is as follows:

[0079] (1) Converter steelmaking: Scrap steel and charge are baked and dried, the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com