Hot-rolled pickled plate for refrigerator compressor shell and production method thereof

A refrigerator compressor, hot-rolled pickling technology, applied in the directions of rolls, metal rolling, metal rolling, etc., can solve problems such as unfavorable welding, and achieve the improvement of transverse printing defects, improve transverse printing problems, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

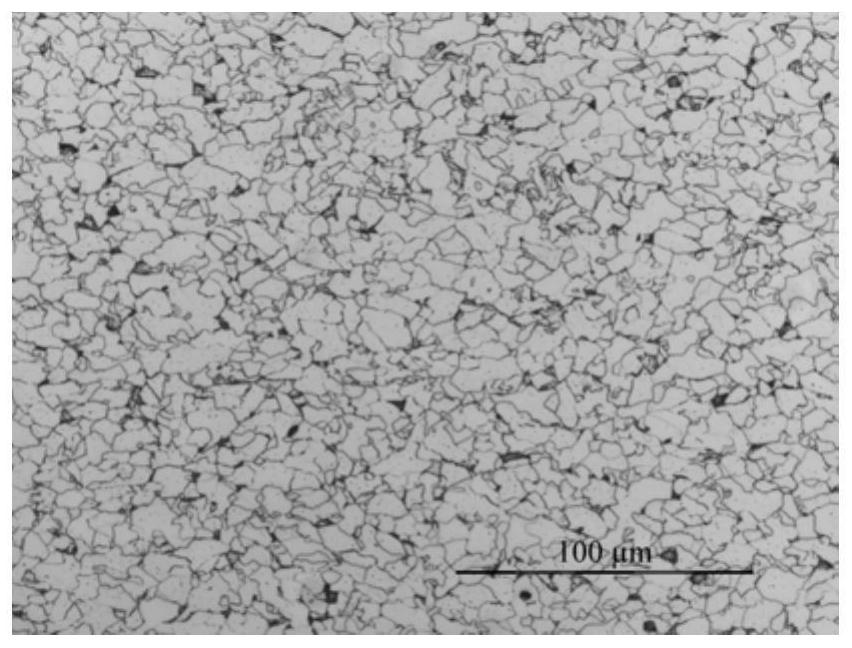

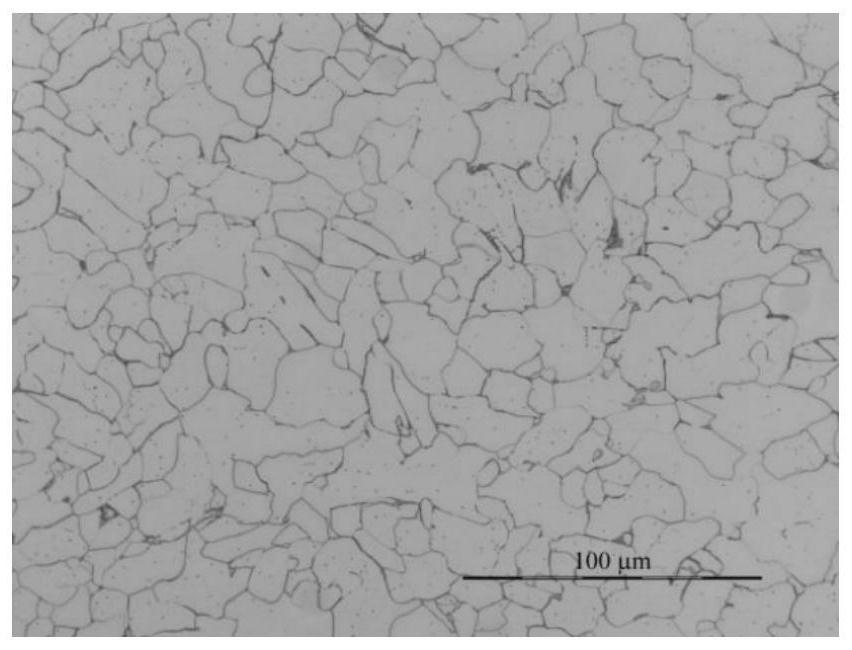

[0036] A hot-rolled pickling plate for a refrigerator compressor shell in this embodiment, the main chemical components of the hot-rolled pickling steel plate are: C: 0.035-0.060%, Si≤0.030%, Mn: 0.30%-0.50 %, P≤0.020%, S:≤0.012%, Al: 0.025~0.050%, N≤0.0045%, and the rest are Fe and unavoidable impurity elements; the microstructure of the hot-rolled pickled steel plate is ferrite + a small amount of pearlite + a small amount of carbide, the grain size of the structure is 10-11, the yield strength range is 260-340MPa, the tensile strength is ≥390MPa, and the elongation after fracture is ≥40%.

[0037] The reason for the limited range of alloy element content in the present invention is as follows:

[0038] C: C is the most economical and effective solid-solution strengthening element to improve the strength. The increase of C content will increase the strength. If the C content is too high, C will exist as undissolved carbides, which will affect the formability of the steel pla...

Embodiment 2

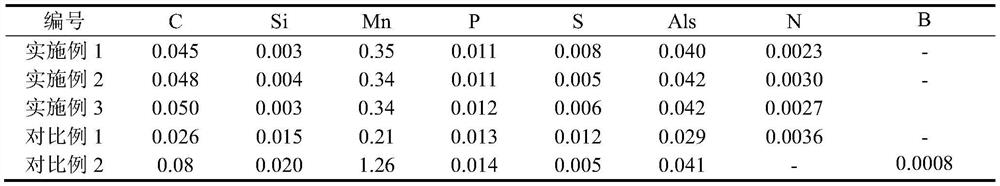

[0046] The production method of a kind of hot-rolled pickling plate for refrigerator compressor shell of the present embodiment, basic structure is the same as embodiment 1, difference and improvement are: the chemical composition (mass percentage) of embodiment of the present invention and comparative example See Table 1, the rest are Fe and unavoidable impurity elements.

[0047] The chemical composition (wt %) of table 1 embodiment and comparative example

[0048]

[0049] According to the requirements of the material composition design of the present invention, the molten iron is pretreated, the slag is removed before and after the slag is removed, and the target S after desulfurization of the molten iron is ≤ 0.005%. Converter top-bottom compound blowing, LF furnace temperature rises and ensures that bottom blowing Ar stirring time is greater than 5 minutes, RH furnace performs vacuum cycle degassing treatment, adopts light treatment process, adjusts target value; ensu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Convexity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com