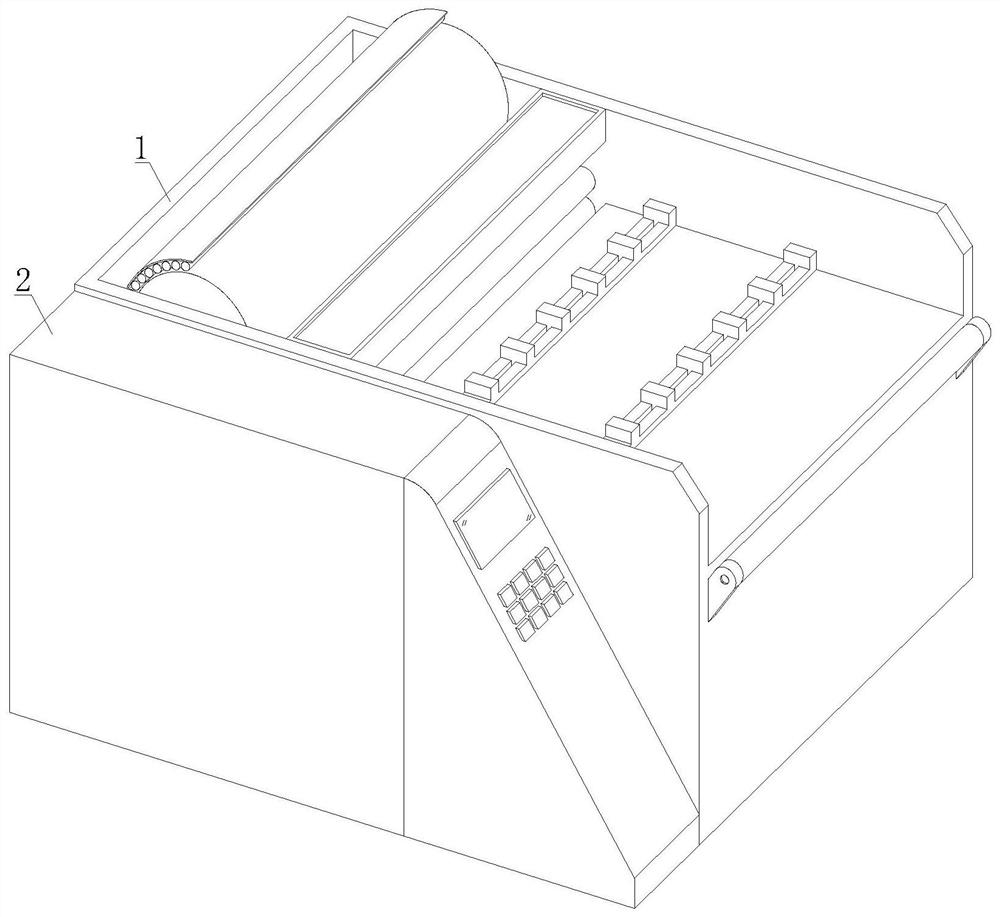

Foil generating device used for machining copper foils and capable of continuously discharging and machining method thereof

A raw foil and copper foil technology, applied in the electrolysis process, electroforming, etc., can solve the problems of unfavorable storage, difficult control of the thickness of electrolytic copper foil, unevenness, etc., and achieve the effect of easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

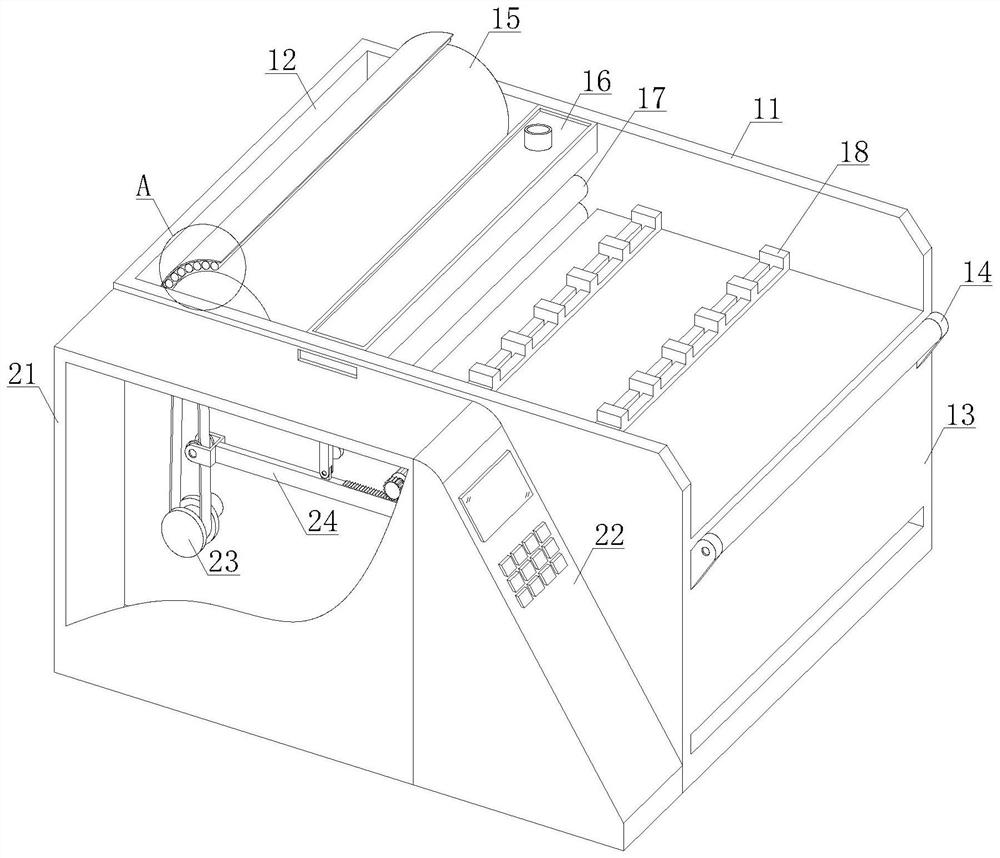

[0043] In order to further and better explain the above examples, the present invention also provides an embodiment, a processing method of a raw foil device capable of continuous discharge for copper foil processing, comprising the following steps:

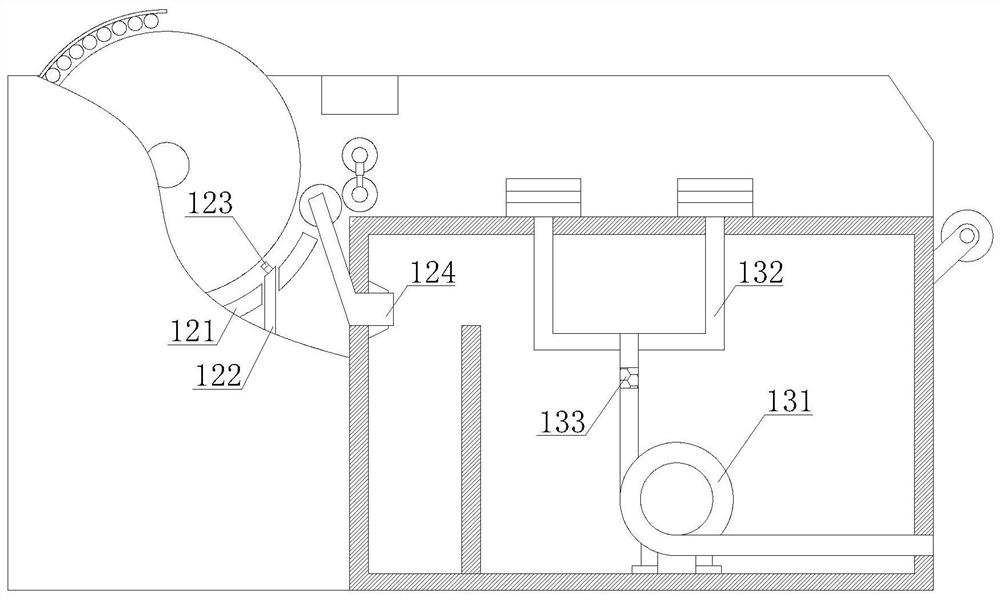

[0044] Step 1: Inject the copper sulfate solution into the electrolytic cell 12, spray the copper sulfate solution toward the surface of the cathode roller 15 from the nozzle 123, produce electrolytic copper foil under the action of the cathode roller 15 and the anode plate 121, and attach the electrolytic copper foil to the surface of the cathode roller 15 The outer surface;

[0045] Step 2: the first pulley 231 drives the cathode roller 15 to rotate, and the surface moisture is sucked dry when passing through the water absorption roller shaft 152;

[0046] Step 3: Cut the two sides of the electrolytic copper foil neatly through the trimming cutter 1532, and the scraps enter the inner box 13 through the feeding plate 124 for col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com