Coal gangue solid waste conversion building materials intelligent system

An intelligent system and technology of coal gangue, applied in the field of coal gangue processing, can solve the problems of lack of full-process production line, poor screening effect, poor dust effect, etc., to improve cleaning efficiency, avoid re-distribution, and fast screening rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

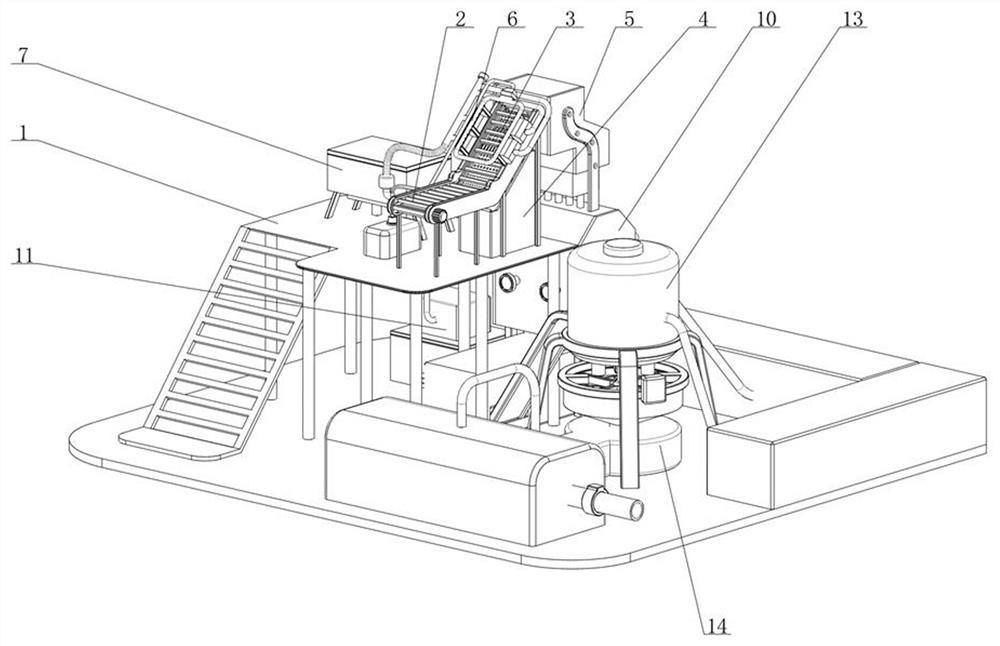

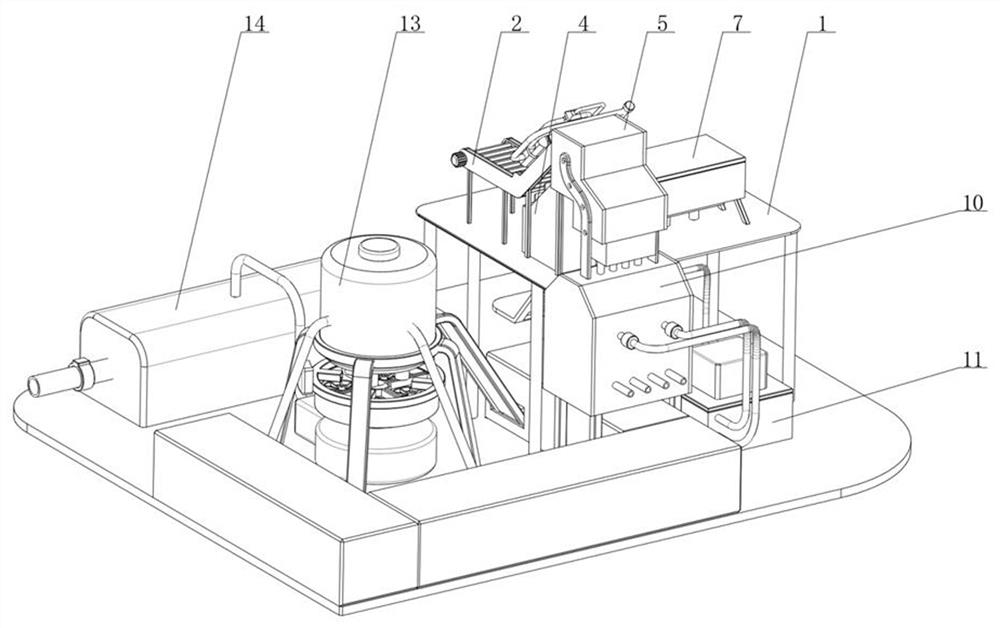

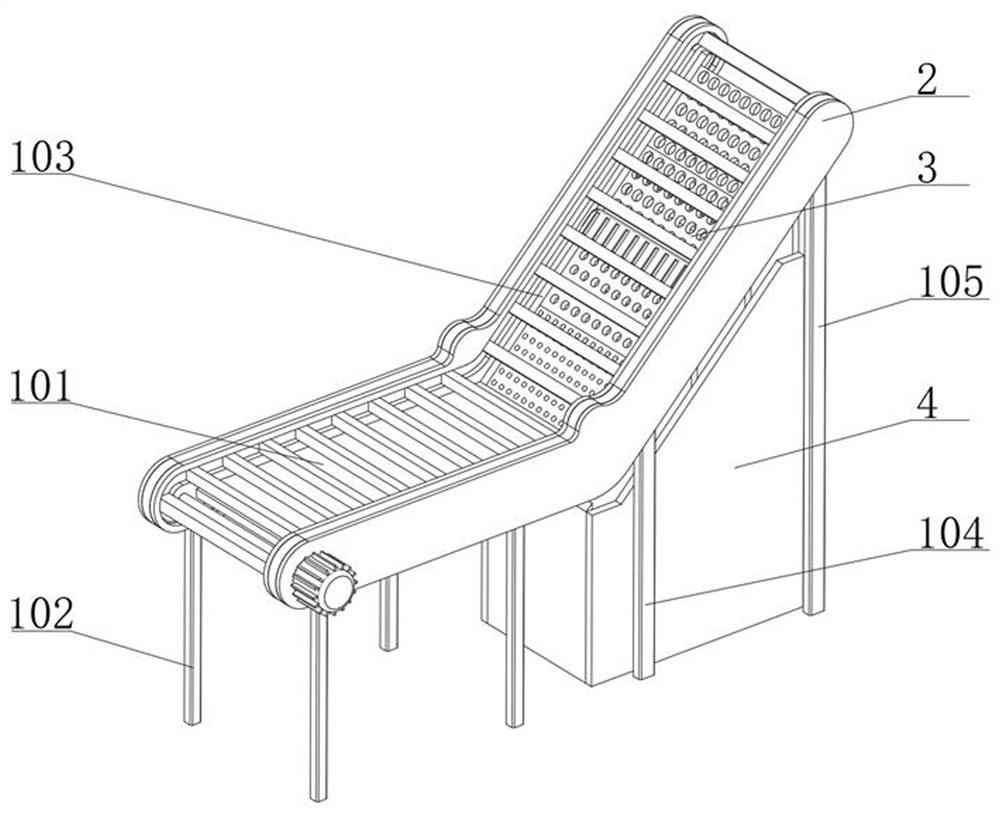

[0040]Please refer to Fig. 1-7, an intelligent system for converting coal gangue solid waste into building materials, including a fixed base plate 1 in a screening area, a feeding platform 101 and an inclined vibrating table 103, and a transmission mechanism 2 with a large inclination angle is arranged on the outside of the feeding platform 101. The inclination transmission mechanism 2 comprises two large inclination conveying boxes 21, a large torque motor 22, a conveying drive shaft 23, two driving wheels 24, two starting point guide wheels 25, two final shock point guiding wheels 26, two elastic Conveyor belt 27 and a plurality of elastic conveying rods 28, the bottom of large inclination angle conveying box 21 is fixedly connected with feeding platform 101 and inclined vibrating table 103, driving wheel 24, starting point guide wheel 25 and final shock point guiding wheel 26 rotate respectively Connected to one end, the middle and the top of the inner chamber of the large-i...

Embodiment 2

[0043] Please refer to Fig. 7-14, the present embodiment has carried out further optimization on the basis of embodiment 1, specifically, the top of inclined vibrating table 103 is provided with gangue screening compartment 5, and the bottom of gangue screening compartment 5 is provided with The sulfur crushing mechanism 9 includes a crushing and separating box 91, a feed pipe 92, an electronically controlled sulfur meter 93, a flat driving shaft 94, a flat cutter head 95, and a crushing discharge pipe 910. The bottom of the pipe 92 is fixedly connected with the pulverization and separation box 91, the flat driving shaft 94 is rotatably connected to the middle part of the inner cavity of the pulverization and separation box 91, the flat knife head 95 is fixedly connected to the outside of the flat driving shaft 94, and the electric control sulfur The meter 93 is fixedly connected to the inside of the pulverizing and separating box 91 , the outside of the pulverizing and separat...

Embodiment 3

[0050] Please refer to Figures 14 and 16, the present embodiment is optimized as follows on the basis of Example 1 or Example 2, specifically, one side of the crushing and separating box 91 is provided with a raw material storage mechanism 13, and the raw material storage mechanism 13 includes a daily powder storage bin 131. Powder storage silo outlet 133, cement silo 134, cement feed screw pump 135, fly ash silo 136, fly ash feed screw pump 137, coal gangue sand bin 138, inclined conveyor 139, coal gangue sand delivery Belt 1310 and material delivery control box 1311, cement silo 134 is fixedly connected with daily powder storage bin 131 through cement feeding screw pump 135, fly ash bin 136 is fixedly connected with daily powder storage bin 131 through fly ash feeding screw pump 137, coal gangue sand The bin 138 is fixedly connected to the daily powder storage bin 131 through an inclined conveying platform 139, and the gangue sand conveyor belt 1310 is rotatably connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com